Wrench (John Arthur Johnson, No. 1,416,197)

The patent by John Arthur Johnson of Leavenworth, Kansas, describes an improved Wrench (Patent No. 1,416,197, 1922). This invention is a heavy-duty adjustable wrench designed for a powerful gripping action through a unique mechanical assembly. Johnson’s primary objective was to create a wrench that is durable, inexpensive to manufacture, and easily disassembled for repair, while providing a “substantially unitary structure” when fully assembled.

Inventor Background: John Arthur Johnson

John Arthur Johnson was an African American inventor based in Kansas during the early 20th century. His 1921 application (granted in 1922) came at a time when industrial tools were evolving to be more ergonomic and modular. Johnson’s design stands out for its sophisticated “swivelled connection” and sectional shank, reflecting a high level of mechanical ingenuity in addressing the wear and tear common in manual labor tools.

Key Mechanical & Structural Systems

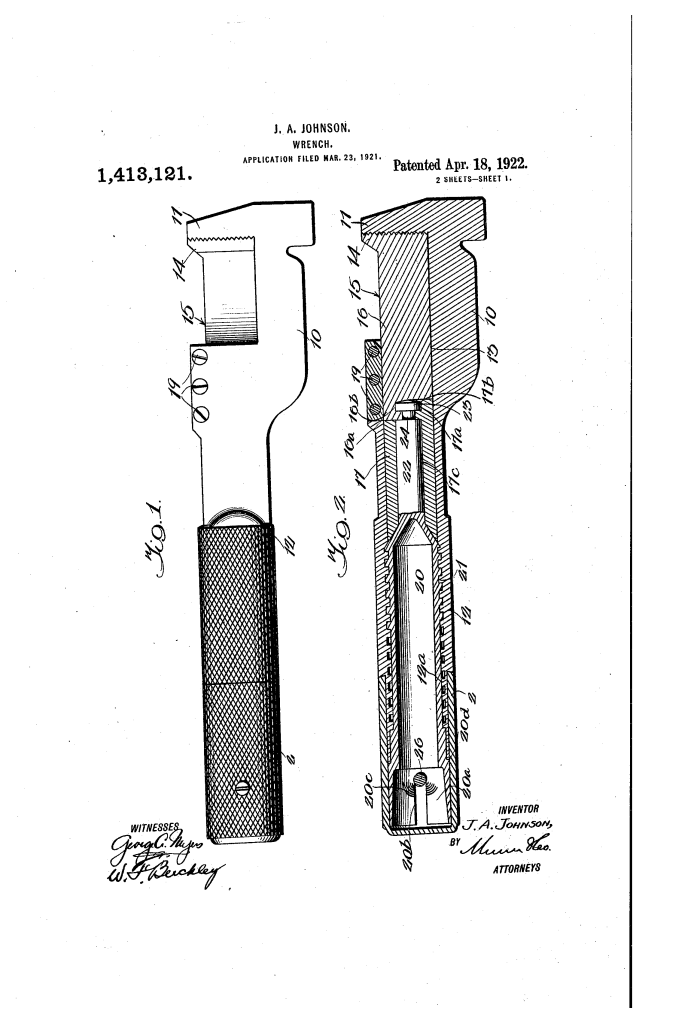

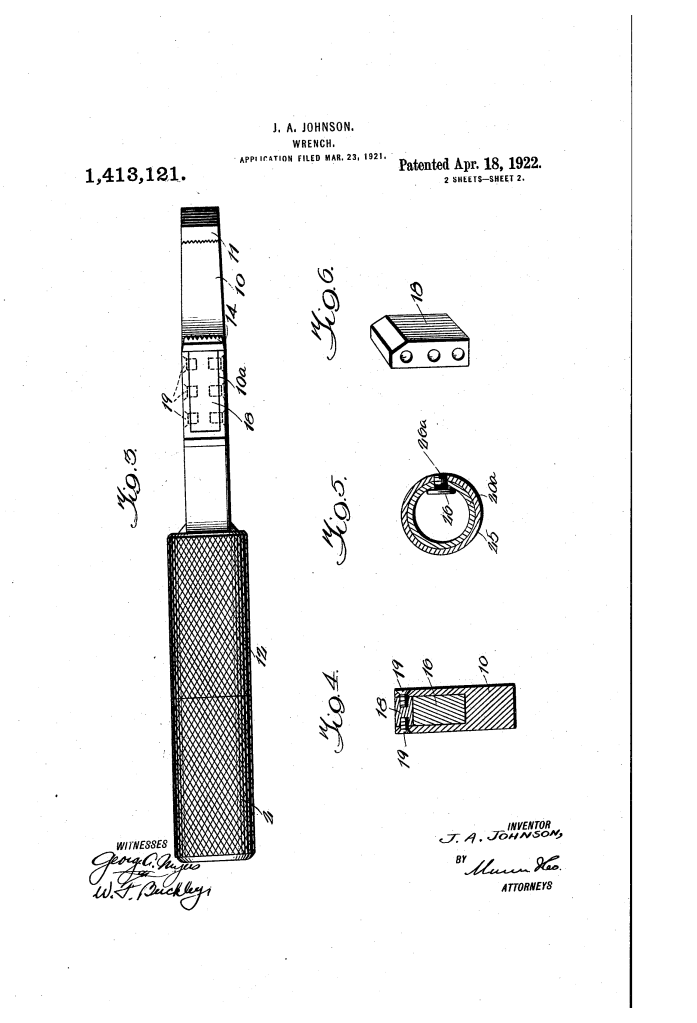

The wrench is built around a main body (10) that houses a sliding jaw system operated by a traveling screw and a rotatable thimble.

1. The Sectional Sliding Shank (15)

- The Inner Jaw (14): Unlike standard wrenches where the jaw and shank are a single solid piece, Johnson’s inner jaw is attached to a sectional shank composed of two parts: Section 16 (attached to the jaw) and Section 17.

- Polygonal Design: The shank sections are polygonal in cross-section, ensuring rectilinear movement (straight-line sliding) without rotating within the body opening (13).

- The Removable Plate (18): A plate on the front of the body allows the user to access the internal coupling. When removed, the jaw and the first section of the shank can be slid out for maintenance.

2. The Traveling Screw and Spindle (20, 22)

- Internal Threading: The handle ends in a tubular shank (12) with internal threads (21).

- The Screw (20): A hollow traveling screw engages these internal threads. As the screw turns, it moves forward or backward within the handle.

- The Coupling: A spindle (22) extends from the screw into the shank of the inner jaw. It terminates in a head (23) and neck (24) that sit within complementary recesses in the shank sections.

- Function: This creates a “swivel” that transmits the linear (push/pull) force of the screw to the jaw while allowing the screw to rotate freely without spinning the jaw itself.

3. The Thimble Drive (25, 26)

- Ergonomic Grip: A large, milled thimble (25) is rotatably mounted on the end of the handle.

- Connection: The thimble is locked to the internal traveling screw by a headed screw (26).

- Operation: By gripping and rotating the thimble with the full hand, the user can exert significantly more torque to tighten the jaws against a bolt compared to using a small thumb-knurl.

Engineering Features and Logistics

| Feature | Hazard/Problem Addressed | Johnson’s Engineering Solution |

| Sectional Shank | Wear and tear on the jaw. | Allows the jaw section (16) to be replaced without replacing the entire internal screw mechanism. |

| Polygonal Opening (13) | Jaw twisting/slippage. | Constrains the shank to a strictly linear path, providing a more stable grip on work. |

| Milled Thimble (25) | Poor grip/hand fatigue. | Provides a large surface area for the hand to apply force, facilitating a “powerful gripping action.” |

| Headed Screw (26) | Difficult disassembly. | A slotted screw accessible through the handle allows the thimble to be removed with a standard screwdriver. |

Significance to Mechanical Tool Design

John Arthur Johnson’s wrench introduced several concepts that parallel modern professional-grade hand tools.

- Modular Maintenance: The idea that a tool should be “easily dissembled for purposes of replacement or repair” was a precursor to modern sustainable design, where components (like the jaw) can be swapped out rather than discarding the whole tool.

- Force Multiplication: By utilizing a large thimble at the base of the tool, Johnson applied the principles of leverage and grip surface area to increase the user’s mechanical advantage.

- Precision Coupling: The use of a swivel head (23) to decouple rotation from linear movement is a sophisticated mechanical solution that ensures the wrench jaws remain perfectly parallel and steady under high pressure.