Woodworking-Machine (Simon Vincent, No. 1,361,295)

The patent by Simon Vincent of Washington, D.C., describes an advanced Woodworking-Machine (Patent No. 1,361,295, 1920). This invention is a portable, hand-operated precision tool designed specifically for cutting mortises—the rectangular holes used for hinges, window jambs, and cabinetry. Vincent’s machine solved the primary problems of manual woodworking: it prevented the wood from splintering at the edges, automatically regulated the depth of each cut to prevent “gouging,” and allowed for lateral adjustment to create wide or “stepped” mortises with a narrow blade.

Inventor Background: Simon Vincent

Simon Vincent was an African American inventor and craftsman living in the District of Columbia during the early 20th century. His 1920 patent addressed the specific needs of carpenters and cabinetmakers who needed to perform high-quality joinery on-site rather than in a factory. While heavy industrial mortisers existed, Vincent’s invention was portable; it could be clamped directly onto a door already hanging on its hinges or a window frame already in position. This focus on portable precision engineering made it a highly practical tool for the building trades of the era.

Key Mechanical Components & Functions

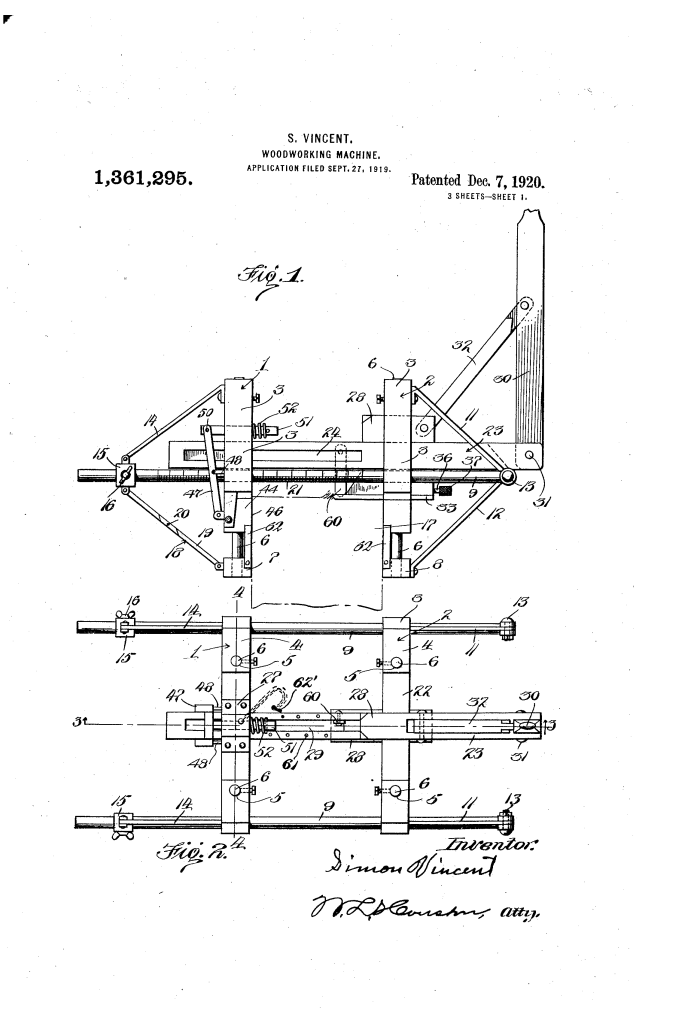

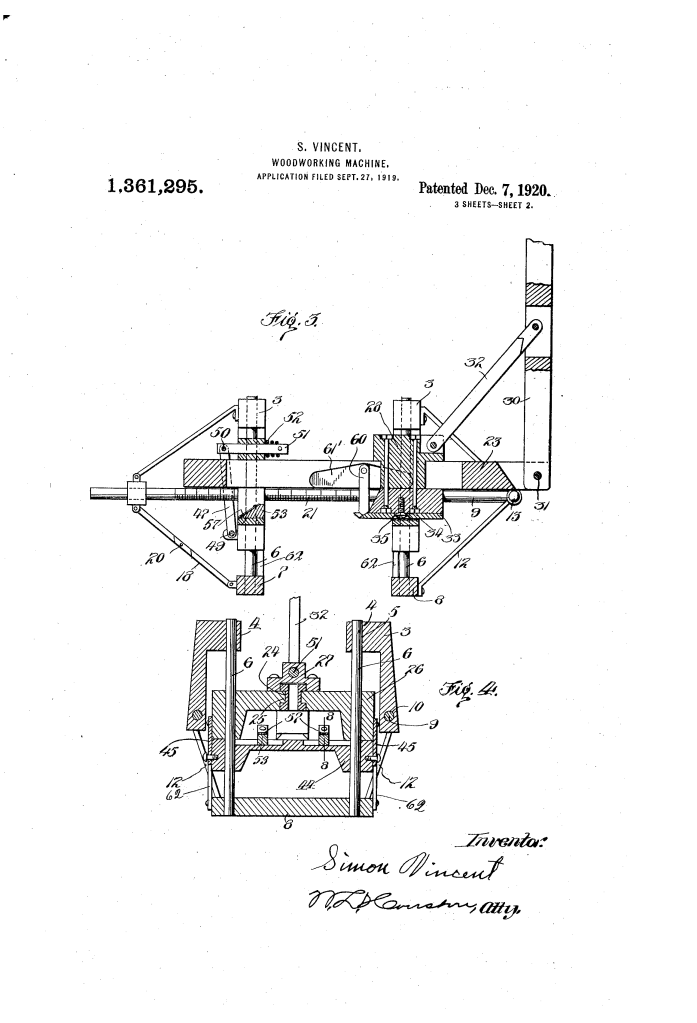

The machine consists of a clamping frame that guides a reciprocating cutter head via a hand lever.

1. The Toggle-Joint Clamping System (15, 18, 19)

- Adjustable Heads: The machine features front and rear heads (1, 2) that slide along side rods (9) to fit the thickness of the wood.

- Toggle Action: Once the heads are loosely set, the operator straightens jointed bracket arms (18).

- Function: This toggle joint exerts a powerful clamping force against the wood (17), ensuring the machine doesn’t shift during the heavy force of the cutting stroke. It also allows for a “quick release” without needing to unscrew the primary set screws.

2. The Reciprocating Cutter Head (28, 30, 32)

- Guide Bar (23): A central guide bar with grooves (24) directs the movement of the cutter head (28).

- Hand Lever (30): The operator pulls a hand lever (30), which is connected to the cutter head via a link (32).

- Function: This reciprocating motion drives the blade through the wood in a clean, shaving action.

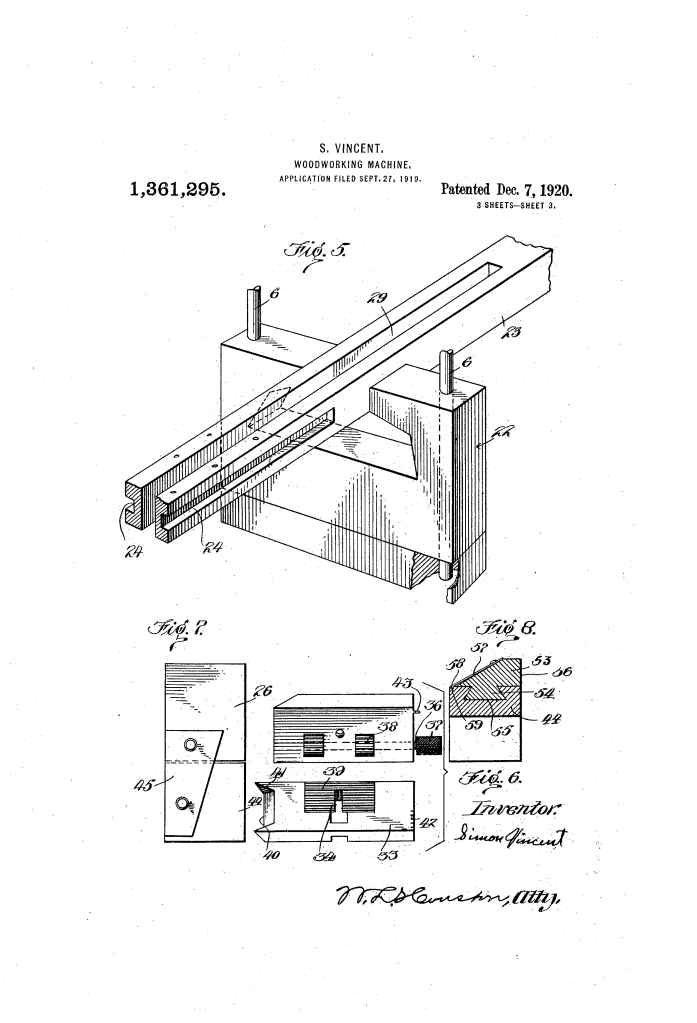

3. Lateral Blade Adjustment (33, 36, 38, 39) (Key Innovation)

Standard mortisers were limited by the width of the blade. Vincent included a “micrometer-style” lateral adjustment.

- Rack and Pinion: The blade (33) features a rack (39) on its upper face.

- Knurled Head (37): By turning a knurled head (37), the operator rotates a shaft with pinions (38).

- Function: This moves the blade sideways without removing the machine from the work. A scale (42) and pointer (43) allow the carpenter to cut wide mortises in multiple precise passes or create “stepped” ornamental cuts.

4. The Anti-Splintering Presser Head (44, 46, 51)

Cutting into wood often causes “ragged edges” or splintering at the end of the stroke.

- Presser Head (44): A flat-faced head that bears against the face of the work.

- Plunger Activation (51): As the cutter head reaches the limit of its forward stroke, it strikes a plunger (51).

- Action: This automatically forces the presser head firmly against the wood at the exact moment of cleavage, supporting the wood fibers and ensuring a clean, neat cut. Slidable lugs (53) can be adjusted to support the wood at the specific width of the mortise.

5. Depth and Stroke Regulation (60, 62)

- The Dog (60): A pivoting dog (60) rests on the surface of the work.

- Function: It limits how far the guide bar can drop, automatically regulating the thickness of the shaving removed in each stroke to prevent the tool from digging too deep.

- Stop Pins (62): Removable pins (62) can be placed in various holes along the guide bar to limit the length of the lever’s stroke, adapting the machine to different hinge leaf widths.

Improvements Over Manual Mortising

| Feature | Manual Chisel and Mallet | Vincent’s Woodworking-Machine |

| Precision | Hard to maintain consistent depth/width. | Automatically regulated depth (60) and scale-adjusted width (42). |

| Edge Quality | Prone to splintering and ragged edges. | Presser head (44) and lugs (53) ensure clean cleavage. |

| Speed | Slow, repetitive striking and clearing. | Rapid, smooth shaving action using lever advantage. |

| On-Site Utility | Difficult to perform on vertical surfaces (doors). | Toggle-clamped design works on any surface in any orientation. |

Significance to Carpentry and Engineering

Simon Vincent’s machine influenced the development of precision hand-tools and portable fabrication.

- The Toggle Clamp Principle: His use of a toggle joint for a woodworking clamp remains a standard design in modern industrial hold-down clamps (like those made by De-Sta-Co).

- Integrated Scale Adjustment: By adding scales directly to the rods and blade, Vincent treated a carpentry tool with the precision of a machine-shop instrument, a precursor to modern router jigs and guide systems.

- Automatic Force Sequencing: The way the cutter head triggers the presser head via the plunger is an early example of synchronized mechanical logic, ensuring the “hold” happens at the exact peak of the “cut.”

- Material Management: The use of dove-tail grooves (55) for the adjustable lugs provided a secure, self-aligning track that is still a staple of high-end tool design today.