Puncture-Proof Pneumatic Wheel (Brinay Smartt, No. 1,051,922)

The patent by Brinay Smartt of Indianapolis, Indiana, describes an innovative Wheel design (Patent No. 1,051,922, 1913). The invention aims to provide the cushioning and resiliency of a pneumatic tire—highly desired for the emerging automobile and bicycle markets—while ensuring that the wheel remains fully operational even if the outer rubber tire is punctured. Smartt achieved this by moving the pneumatic tube away from the road surface and placing it deep within the wheel structure, where it is protected by a metallic “deformable” rim.

Inventor Background: Brinay Smartt

Brinay Smartt was an African American inventor based in Indianapolis, a city that was a major hub of the early American automobile industry. His patent reflects the primary anxiety of early motorists: the “blowout.” In 1912, rubber technology was primitive, and flat tires were frequent and dangerous. Smartt’s engineering approach was to treat the pneumatic tube as a mechanical spring rather than a road-contact surface. His design shows a sophisticated grasp of modular assembly and reciprocating mechanical parts.

Invention and Mechanism (Simplified)

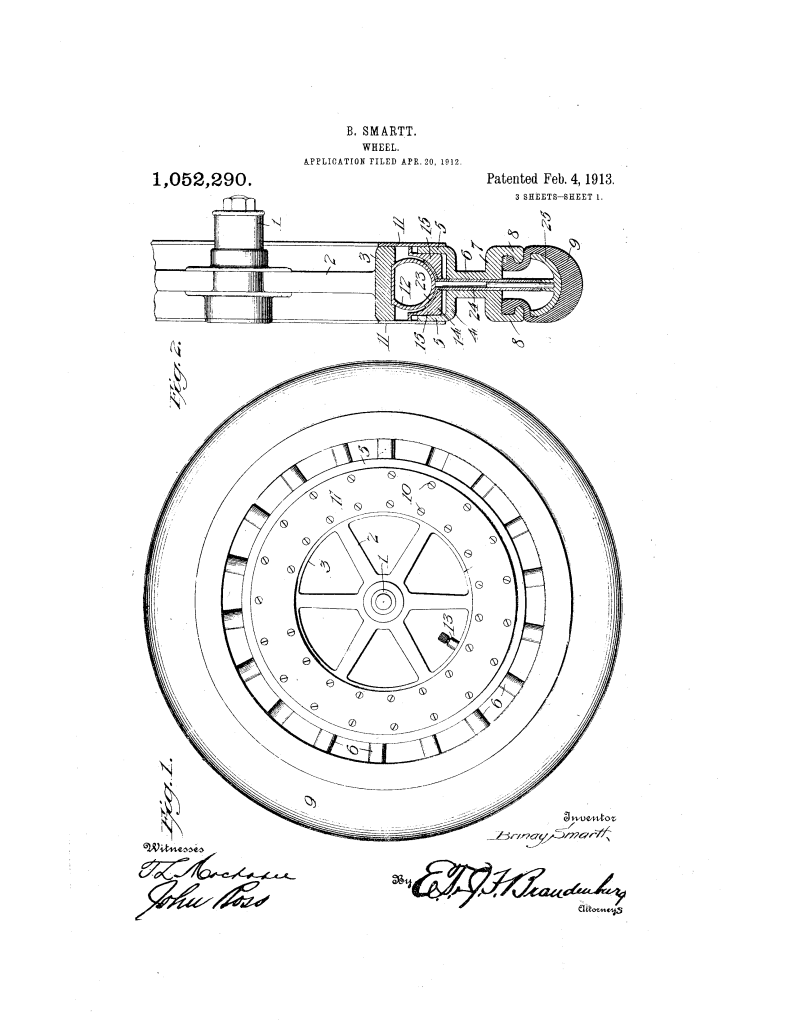

The wheel functions by using an internal air tube to push a series of mechanical plungers outward against a segmented rim.

1. The Protected Pneumatic Core

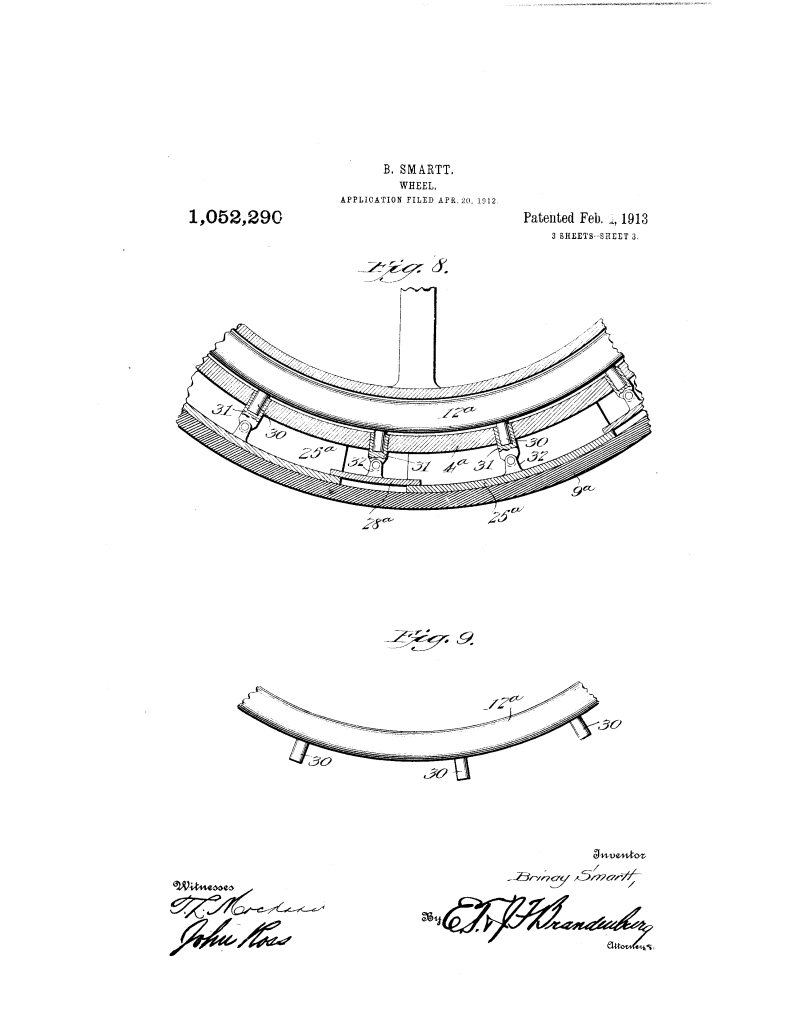

- Inner Felly (3) and Inner Rim (4): Unlike a standard wheel where the tube is on the outside, Smartt placed a pneumatic tube (12) in a chamber between the wooden spokes and a secondary inner metal rim.

- Retaining Rings (11): Metal plates bolt to the sides of the wheel to keep the tube safely encased. Because it never touches the ground, it cannot be punctured by nails or glass.

2. The Plunger and Spoke System

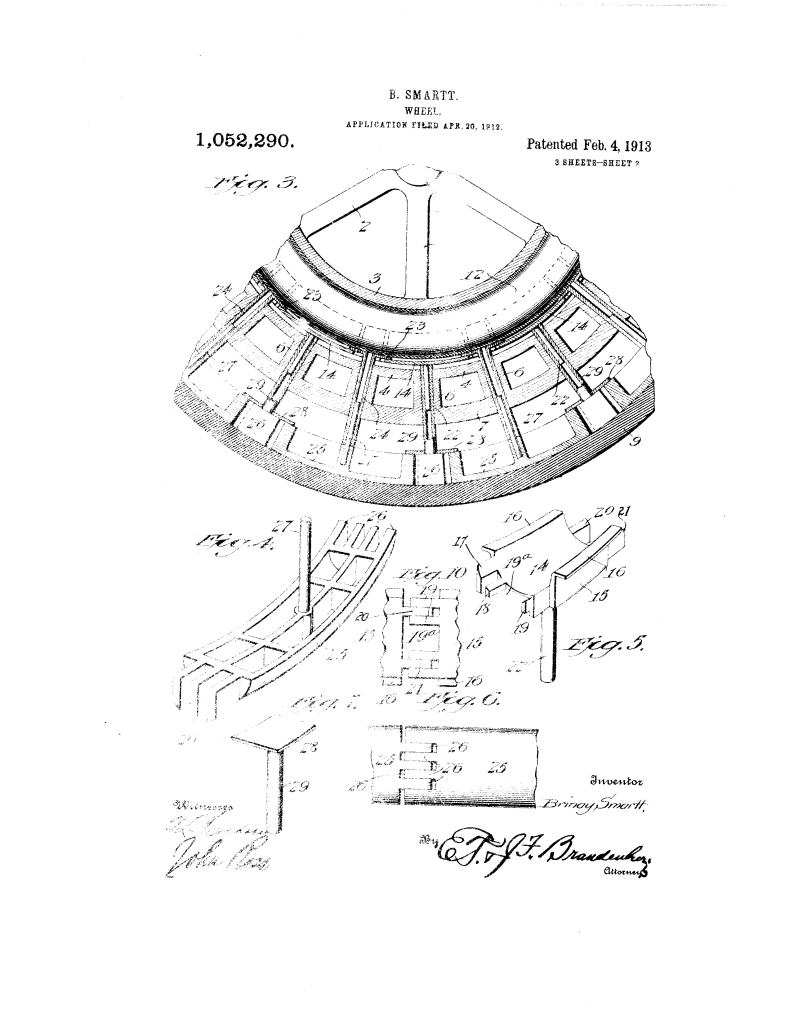

- Plunger Members (14): A series of curved metal blocks ($14$) sit directly on the air tube.

- Hollow Spokes (6): The outer part of the wheel features hollow metal spokes.

- Function: As the tube is inflated via the nipple (13), it expands and pushes the plunger members (14) and disks (23) outward through the hollow spokes.

3. The Deformable Outer Rim (Key Innovation)

- Interlocking Units (25): The outer rim, which holds the solid rubber tire (9), is not a solid circle. It is made of individual metal sections or units (25).

- Interlocking Tongues (26): Each section has “fingers” or tongues that slide into the next section.

- Function: This allows the rim to expand or contract. When the internal tube is highly inflated, the plungers push these sections out, tightening the tire. When the wheel hits a bump, the sections can move slightly inward against the air pressure, providing a “cushioning” effect without the air ever being exposed to the road.

Concepts Influenced by This Invention

Brinay Smartt’s wheel influenced the development of non-pneumatic tires and mechanical suspension systems.

- The “Air-Spring” Principle: Smartt’s use of a pneumatic bladder to actuate mechanical plungers is a direct mechanical ancestor to modern air suspension systems used in trucks and luxury cars to maintain ride height and absorb shocks.

- Run-Flat Capability: By using a segmented metal rim as the primary structure, the wheel could continue to roll even if the internal tube failed, a concept that evolved into the run-flat tires and “tweels” (airless tires) used by military and industrial vehicles today.

- Modular Rim Construction: The logic of a segmented, interlocking rim influenced the design of heavy-duty tracks for tanks and bulldozers, where individual links must move independently while remaining a cohesive unit.

- Internalized Component Protection: The engineering philosophy of moving a fragile but essential component (the air tube) to a protected internal housing remains a standard practice in “hardened” industrial design.