Well-Drilling Tool (Clifton M. Ingram, No. 1,542,776)

The patent by Clifton M. Ingram of Porter, Oklahoma, describes a Well-Drilling Tool (Patent No. 1,542,776, 1925). This invention is a specialized “fishing” or recovery tool designed for deep-well operations, such as oil or artesian drilling. Its primary objective is to prevent the total loss of a well by providing a way to clear debris—like sand and mud—from around a drill stem that has become stuck deep underground.

Inventor Background: Clifton M. Ingram

Clifton M. Ingram was a prolific African American inventor based in Oklahoma during the height of the state’s oil boom. In the 1920s, a “stuck” drill stem often meant abandoning the entire well, costing companies thousands of dollars and months of labor. Ingram’s engineering background led him to design a recovery tool that could be deployed around the existing obstruction, a significant advancement over tools that required the stem to be removed first.

Key Mechanical & Operating Systems

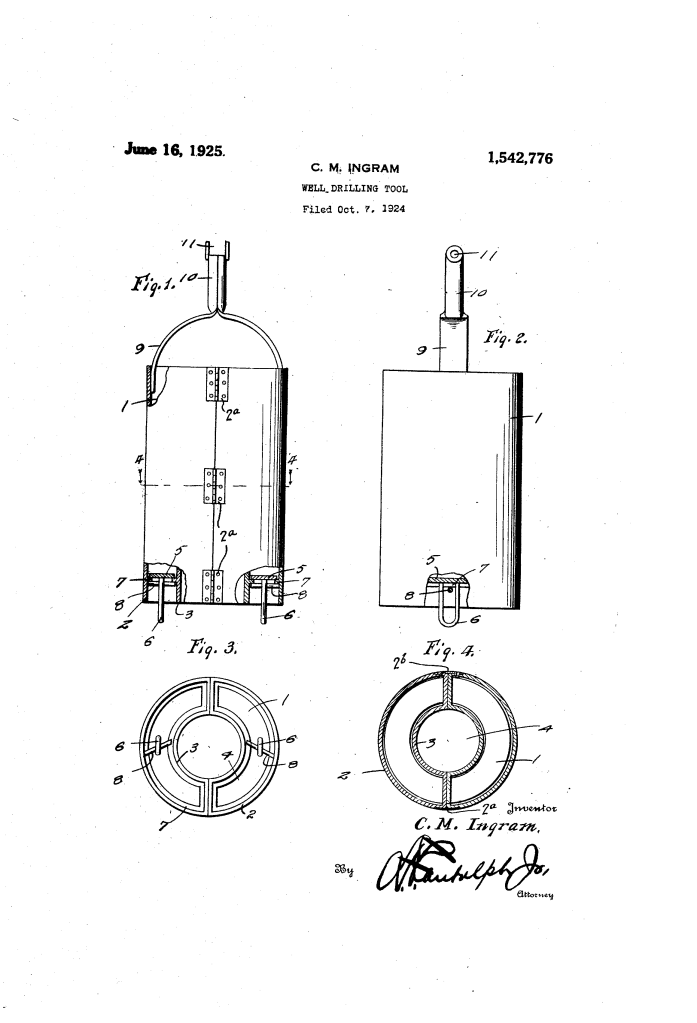

The tool is designed as a “split cylinder” that can be latched onto a drill stem already in the hole.

1. The Hinge and Latch System (2*, 2b)

- Semi-Cylindrical Sections: The tool consists of two similar halves.

- Hinges (2):* These allow the tool to open wide so it can be wrapped around the stuck drill stem.

- Latches (2b): Once positioned around the stem, the tool is latched shut to form a complete double-walled cylinder. This allows the drill stem to pass freely through the central opening (4) while the tool works on the debris surrounding it.

2. The Double-Wall Debris Chamber (1, 2, 3)

- Space (1): Between the outer wall (2) and inner wall (3) is a hollow annular space.

- Function: This space acts as a storage chamber for sand, mud, and cuttings. By capturing these materials inside the walls, the tool removes the friction “binding” the drill stem to the borehole wall.

3. Upward-Opening Valve Mechanism (5, 6, 7)

The bottom of the tool is equipped with a clever “trap-door” system:

- Valves (5): These are located at the bottom of the annular space and open only in an upward direction.

- Loop Extensions (6): These projections hit the sand/mud at the bottom of the well. The pressure of the debris against these loops forces the valves open as the tool is lowered.

- Collection and Retention: As the tool is lifted, gravity and the weight of the collected material force the valves back down onto their inner seats (7), trapping the debris inside for removal.

Engineering Features and Safety Logic

| Feature | Problem Addressed | Ingram’s Engineering Solution |

| Sectional Bail (9, 10) | Operational deployment. | A split lifting handle (bail) that allows the tool to be suspended by a cable even when wrapped around a stem. |

| Inner Wall (3) | Protecting the drill stem. | Creates a smooth conduit so the recovery tool doesn’t accidentally damage or further jam the stuck stem. |

| Cross Pins (8) | Valve failure. | Pins that cooperate with the loop extensions to prevent the valves from opening too far and getting jammed in the “up” position. |

| Cylindrical Formation | Structural integrity at depth. | The hinged design ensures the tool maintains a perfectly circular profile, preventing it from getting stuck itself against the well walls. |

Significance to Petroleum Engineering

Clifton Ingram’s tool was a masterclass in emergency intervention engineering.

- The “Around-the-Pipe” Concept: This was a radical departure from contemporary “bailers” which could only be used in an empty hole. Ingram recognized that the debris is the problem, and removing it without pulling the pipe is the most efficient solution.

- Mechanical Automation: The use of hydrostatic and mechanical pressure to open the valves (via the loops) eliminated the need for complex surface-controlled hydraulics, making the tool reliable in the harsh, high-pressure environment of a deep well.

- Salvage Value: By preventing the abandonment of wells, Ingram’s tool provided a direct economic benefit to the drilling industry, particularly in the challenging clay and sand strata of the mid-continental United States.