Waste-Trap for Basins, Closets (Samuel E. Thomas, No. 371,107)

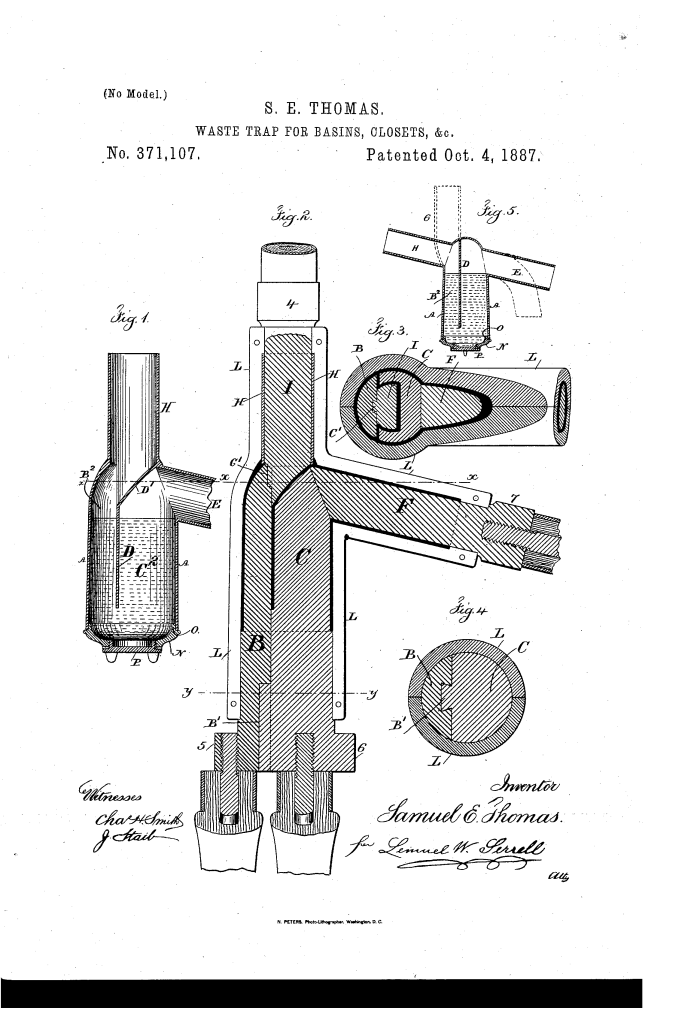

The patent by Samuel E. Thomas of Brooklyn, New York, describes an improvement in Waste-Traps (Patent No. 371107, 1887). The invention focuses on a more durable and easily manufactured plumbing trap for sinks, basins, and water closets. It introduces a hybrid construction method—combining cast metal for the body with wrought-lead for the inlet—to ensure the trap is both easy to clean and simple to install without cracking.

Inventor Background: Samuel E. Thomas

Samuel E. Thomas was an African-American inventor and master plumber based in Brooklyn during the late 19th century. His work was pivotal during a time when urban sanitation was undergoing rapid modernization. Plumbing traps are essential for public health, as they hold a water seal that prevents sewer gases from entering living spaces. Thomas’s patent addressed common technical failures in lead casting, such as the fragility of cast pipes when being fitted to fixtures. By innovating in both the mechanical design and the metallurgical process of the trap, he contributed to the reliability of Victorian-era home sanitation.

Invention and Mechanism (Simplified)

The waste-trap is designed to be easily cast in a mold and features an internal “dam” or partition to prevent siphoning.

1. The Cylindrical Trap Body (A)

- Design: The body of the trap is nearly cylindrical. This specific shape is intended to allow the cores (B and C)—the solid pieces used during the casting process to create the hollow interior—to be easily withdrawn once the metal has cooled.

- The Partition or Dam (D): Inside the body is a vertical wall or dam that terminates just above the bottom.

- Anti-Siphoning Feature: Thomas placed the dam closer to the inlet side. This creates a larger volume of water on the outlet side (C), which significantly reduces the risk of the water seal being “siphoned” away when a large volume of water flushes through.

2. Hybrid Material Construction (Key Innovation)

- Cast Body vs. Wrought Inlet: The body (A) and outlet (E) are cast in a mold. However, the inlet-pipe (H) is made of wrought-lead (formed by a hydraulic press).

- Function: Wrought-lead is more ductile (flexible) than cast metal. This allows the plumber to “spread or flange” the end of the pipe during installation to connect it to a sink or basin without the lead cracking—a common problem with purely cast traps.

- Casting Process: The wrought pipe is tinned and inserted directly into the mold. When the molten metal for the body is poured, it melts and solders itself to the wrought pipe, creating a single, seamless unit.

3. Cleaning and Accessibility

- Brass Ring (N) and Cap (P): At the bottom of the trap, a brass ring is soldered into place. It features an internal screw thread for a removable cap (P).

- Function: This “trap-screw” provides easy access for cleaning out debris or “muck” that may settle at the bottom of the dam, a necessity for maintaining proper drainage.

Concepts Influenced by This Invention

Samuel E. Thomas’s waste-trap influenced the manufacturing of plumbing hardware and the standards of domestic sanitation.

- Metallurgical Bonding in Manufacturing: The method of inserting wrought components into a cast mold to create a hybrid-material part is a sophisticated manufacturing technique still used to combine the strength of one material with the flexibility or precision of another.

- Volumetric Siphon Prevention: The logic of an off-center dam to maintain a “heavier” water seal on the discharge side is a core principle in hydraulic engineering used to prevent gas leaks in modern waste systems.

- Standardized Clean-Out Ports: By incorporating a brass-threaded ring and cap, Thomas helped standardize the “clean-out” feature that is now a legal requirement in modern building codes for all plumbing traps.

- Ductility in Field Installation: Recognizing that a product must survive the “rough-in” process of installation led to more resilient plumbing designs that accounted for the physical stresses applied by tradespeople during assembly.