Volume-Controlling Means for Mechanical Musical Instruments (Joseph H. Dickinson, No. 926,472)

The patent by Joseph H. Dickinson of Cranford, New Jersey, describes Volume-Controlling Means for Mechanical Musical Instruments (Patent No. 926,472, 1909), designed for pneumatically operated musical instruments like player pianos. The primary object is to control the volume of sound (accent) produced by modifying the pneumatic force supplied to various note-sounding devices, allowing for control by both the operator’s hand and automatically by perforations in the music sheet.

Inventor Background: Joseph H. Dickinson

Joseph H. Dickinson (c. 1855–1930) was a pivotal African-American inventor, engineer, and master craftsman known for his work in the musical instrument industry. Having already patented improvements in reed organs and tracker compatibility, this invention represents his advanced work in automatic musical expression, tackling the complex problem of adding dynamic volume control (accenting) to a mechanical player system.

Invention and Mechanism (Simplified)

The device is a pneumatic control center that allows the player to manually override the music roll’s automatic volume markings, or lets the roll define complex, simultaneous accents on different parts of the keyboard.

1. Volume Control Center

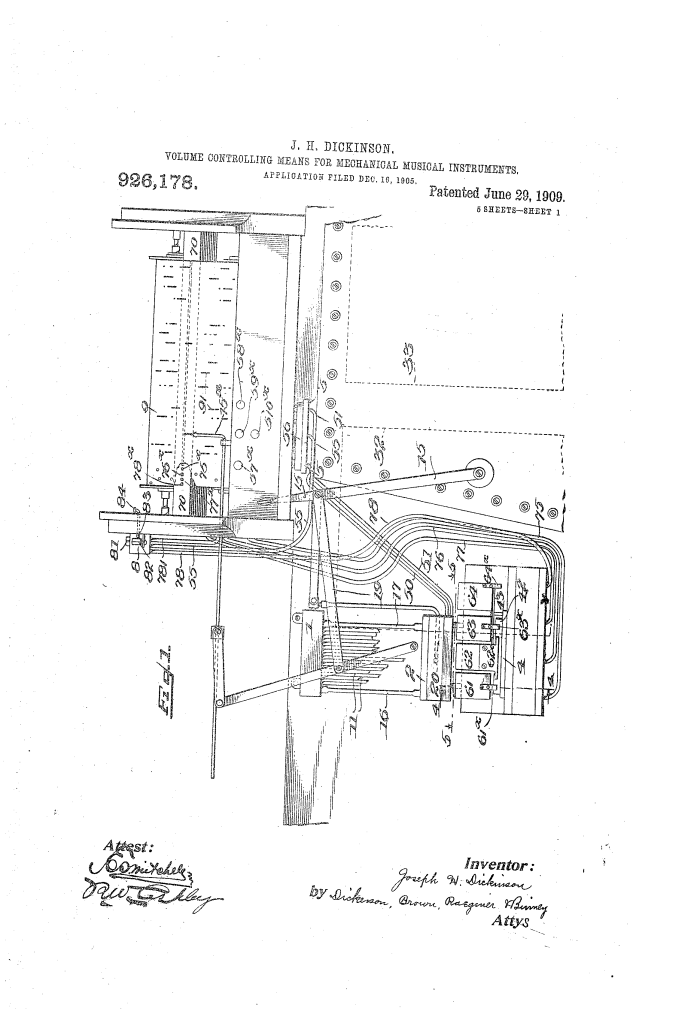

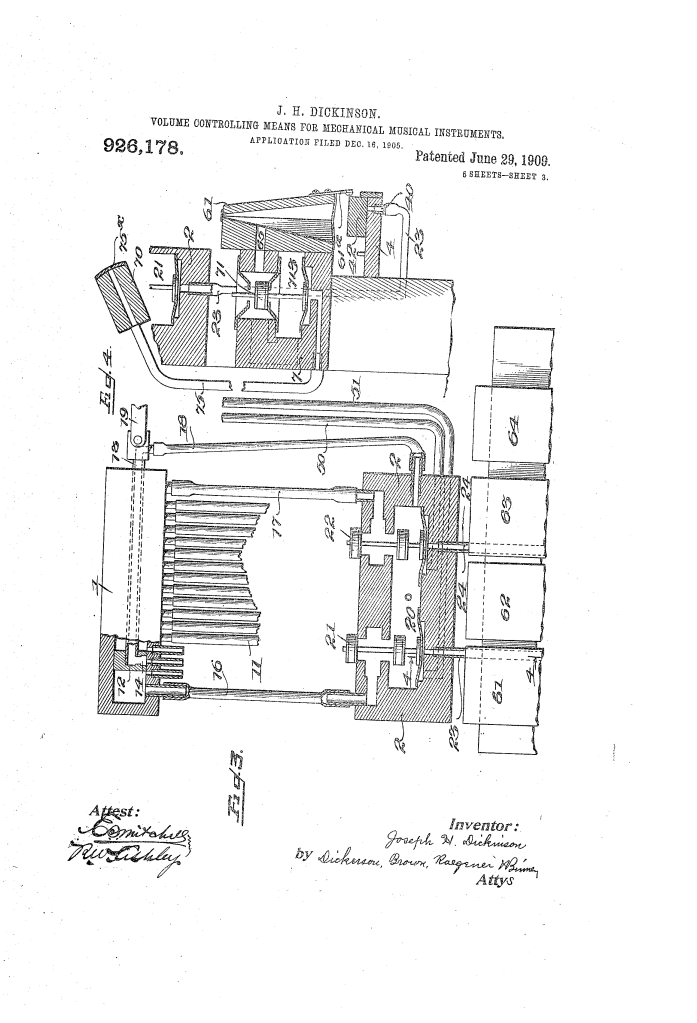

- Valve Casing (1) and Slidable Valve (12): A main casing containing a valve (12) that can slide to cover and uncover a series of output tubes (11).

- Function: The valve (12) is connected to a hand lever (15). Moving the lever slides the valve, which determines which note tubes (11) receive the accenting air. This allows the operator to manually shift the “accent point” across the musical scale (e.g., accenting only the bass notes).

2. Manual and Automatic Control (Key Innovation)

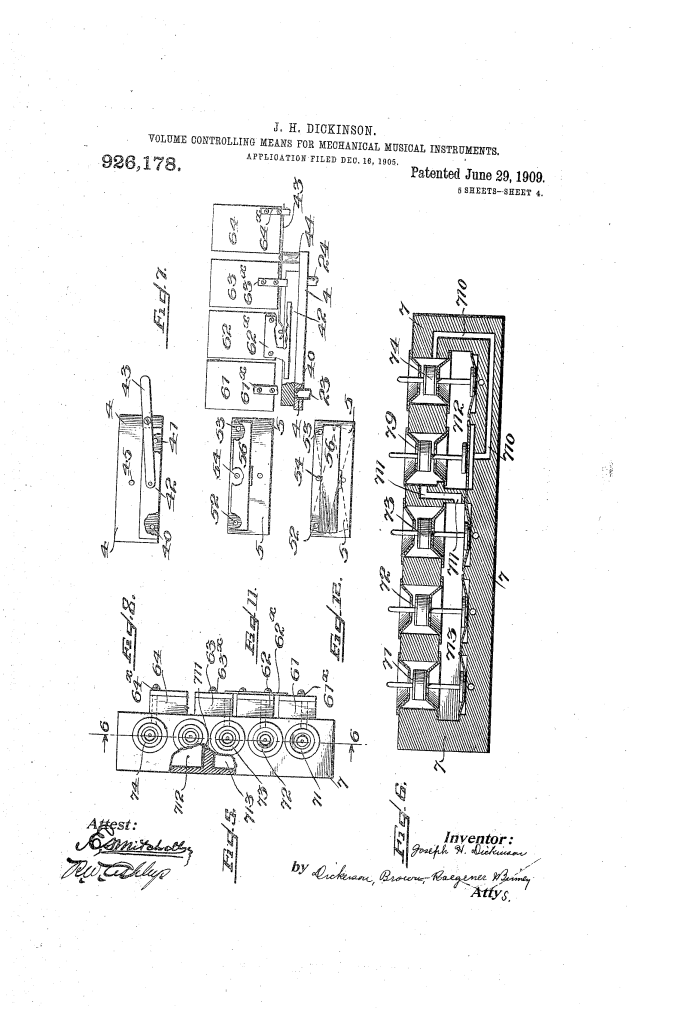

The system uses multiple pneumatic circuits (valves 21, 22 and corresponding bellows 61-64) to control the air supply to the entire system.

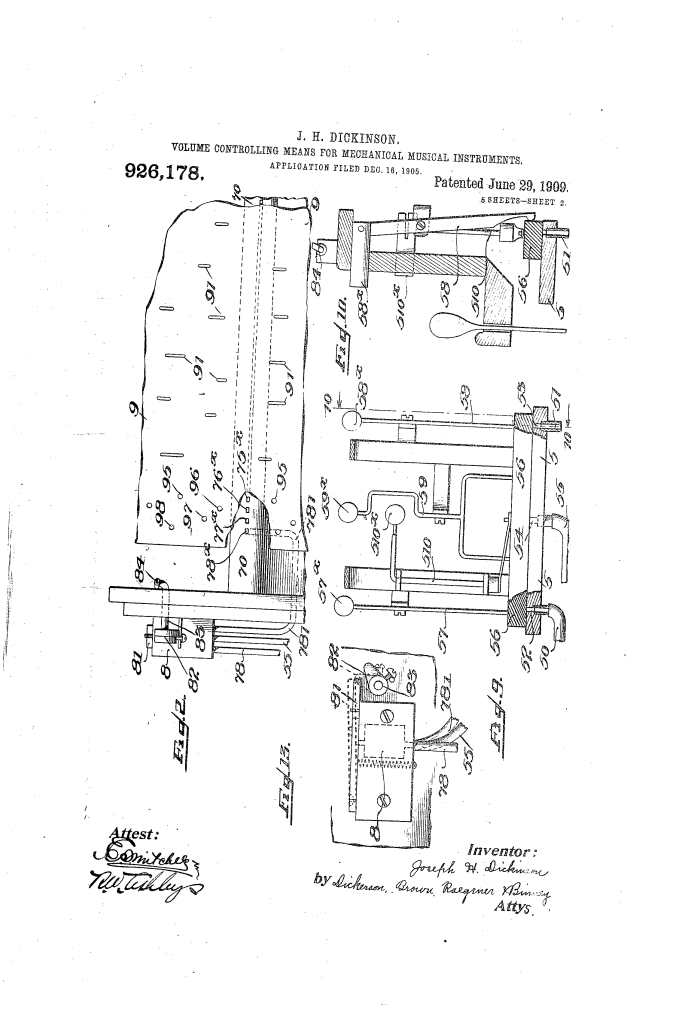

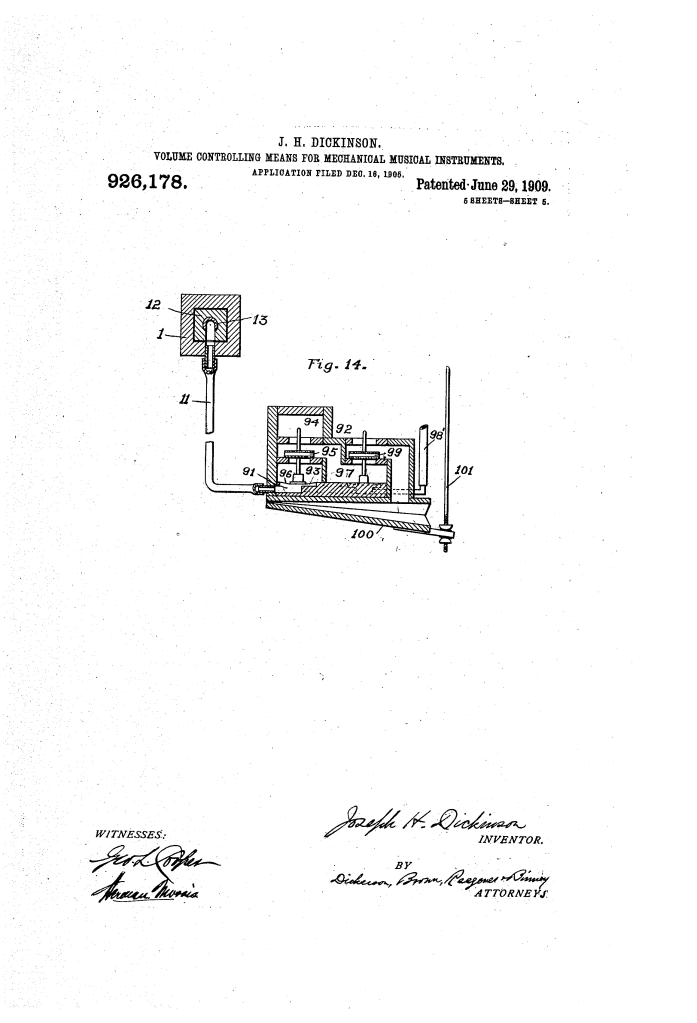

- Automatic (Tracker) Control: The music roll (9) has additional rows of perforations (95, 96, 97, 98) . These perforations register with special ducts ($75^*$–$78^*$) on the tracker.

- Function: Air pulses through these ducts activate the bellows (61, 62, 63) which, by moving a valve bar (42), automatically open air supplies to the left or right groups of note connections (16, 17), giving the automatic accent directed by the music roll.

- Manual Control (Push Buttons 57, 58, etc.):** Push buttons activate levers (57, 58, etc.) which move a separate unitary valve (56).

- Function: Pressing a button manually opens the air supply to the left, right, or both groups of notes, allowing the operator to apply accent at will.

3. Alternative Operation (Override/Interlock)

- Override: The manually controlled valve (56) is designed to simultaneously render the automatic tracker-controlled means inoperative.

- Function: This ensures that when the player uses their hand to control the accent, the automatic markings on the music sheet are disregarded, preventing interference and allowing the player’s taste to prevail.

- Accent Method: The pneumatic force (air tension) delivered through the tubes (11) is routed through a secondary action (Fig. 14), which causes the striking mechanism to operate with increased force (higher wind tension), thereby increasing the volume (accent).

Concepts Influenced by This Invention

Dickinson’s device influenced subsequent mechatronic and musical instrument design by pioneering multi-source control logic and selective input overrides.

- Manual Override and Interlock: The core concept of providing two alternative control sources (automatic music roll vs. manual push button) where the manual input simultaneously disables (overrides) the automatic input influenced the design of industrial control panels and safety systems that require a clear, non-interfering user override mode.

- Zoned/Group Control: The ability to independently apply accent to groups of notes (left-hand range vs. right-hand range) and to shift the point of accentuation across the keyboard (valve 12) influenced the design of modern digital sound synthesizers and controllers that allow for selective processing or accenting of different frequency ranges or MIDI note groups.

- Pneumatic Control Logic: The system’s use of complex pneumatic circuitry (cascading valves and bellows 61–64) to perform intricate logic sequences (e.g., if perforation $95$ is open, then collapse bellows $61$) influenced the design of industrial automation relying on fluidic or pneumatic logic before electronics became dominant.

- Musical Expression Automation: This invention represents a significant early step in the effort to mechanize the nuance and expression of music, moving player pianos beyond simple note delivery to dynamic musical performance.