Adjustable Tracker for Pneumatic Playing Attachments (Joseph H. Dickinson, No. 915,368)

The patent by Joseph H. Dickinson of Cranford, New Jersey, describes an Adjustable Tracker for Pneumatic Playing Attachments (Patent No. 915,368, 1909), designed for musical instruments like player pianos. The object is to provide a new and improved tracker board with two independent rows of tracker holes (e.g., 65 notes and 88 notes) and means for easily and rapidly switching between them.

🎶 Inventor Background: Joseph H. Dickinson

Joseph H. Dickinson (1855– 1928) was a highly significant African-American inventor, engineer, and master craftsman who made crucial contributions to the musical instrument industry, particularly in the design of organs and player pianos.

Career and Expertise

- Residence and Employment: Dickinson was born in Michigan and worked for many years in Detroit. He later resided in Cranford, New Jersey.

- The Music Industry: He was centrally involved in the manufacturing of musical instruments during the late 19th and early 20th centuries. He worked as an engineer for the Whitney Organ Company in Detroit. His expertise was so highly valued that he later worked for the Aeolian Company (which acquired Whitney), a major manufacturer of player pianos and organs.

- Patents and Focus: Dickinson held several patents, all focused on improving the functionality, sound quality, and production efficiency of musical instruments:

- Reed-Organ (1899): Patented innovations in the qualifying tubes (acoustic chambers) to produce a louder, richer sound similar to a pipe organ, improving the instrument’s tonal quality.

- Adjustable Tracker (1909): This invention solved a crucial market problem for player pianos by creating a mechanism that allowed a single instrument to switch seamlessly between older 65-note music rolls and modern 88-note rolls, enhancing compatibility and market value.

Significance

Dickinson’s work elevated the quality of mass-produced instruments and demonstrated complex engineering mastery in the emerging field of pneumatic control systems for mechanical instruments. His patents illustrate the vital, often technical, role Black inventors played in the highly competitive consumer product industries of the era.

Invention and Mechanism (Simplified)

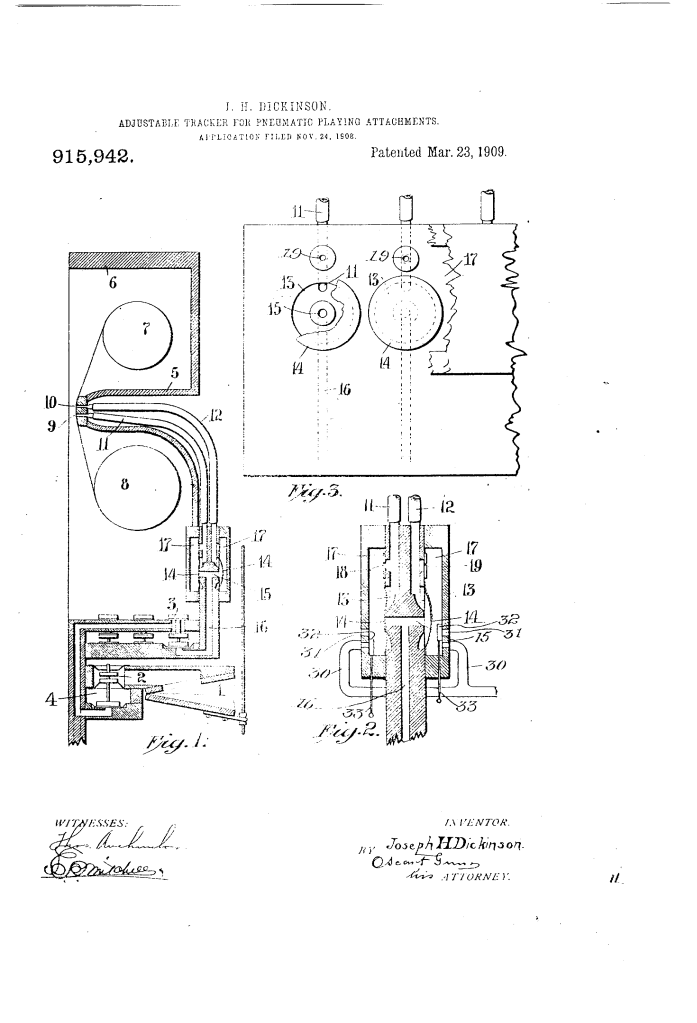

The device is a pneumatic switching system that routes air from one of two sets of tracker holes (for different size music rolls) to the corresponding pneumatic player mechanisms.

1. Dual Tracker System

- Hollow Tracker Board (5): This board is provided with two longitudinal rows of holes (9 and 10) in its outer edge.

- Roll Compatibility: The rows differ in number and size (e.g., 65 holes for older rolls, 88 holes for standard modern rolls).

- Ducts: Each hole (9 or 10) is connected to its own duct (11 or 12).

2. Pneumatic Switching (Key Innovation)

- Transverse Duct (15): The ducts from the two different note rows (11 and 12) terminate in a chamber (13) which is connected to a single transverse duct (15).

- Diaphragm Valves (14): A flexible diaphragm valve is positioned at each end of the transverse duct (15).

- Control Chambers (17): The valves (14) are located within two separate air chambers (17).

- Function: By admitting air (or connecting to atmosphere) into one chamber (17) and exhausting air (connecting to suction) from the other, the pressure differential forces one diaphragm valve (14) onto its seat and pulls the other valve off its seat. This effectively switches the connection of one note row (e.g., 65-note) ON and the other (88-note) OFF to the striker pneumatics.

3. Compensating for Hole Size

- Bleed Holes (18, 19): Each duct (11 and 12) is connected to its corresponding control chamber (17) by a small bleed hole.

- Variable Size: The bleed holes (18) for the larger tracker holes (65-note row) are made larger than the bleed holes (19) for the smaller tracker holes (88-note row).

- Function: This subtle difference in size ensures that the pneumatic action for both rows operates with the same speed and reliability, compensating for the different volumes of air flowing through the different sized tracker holes.

Concepts Influenced by This Invention

Dickinson’s tracker influenced subsequent design in pneumatic control and instrument design by pioneering differential air pressure switching and flow compensation.

- Pneumatic Switching for Modularity: The primary influence is the elegant use of pressure-differential diaphragm valves to create an instantaneous, non-mechanical switch between two modular inputs (the 65-note roll and the 88-note roll). This concept is foundational to pneumatic control systems and influenced the design of multi-format media players.

- Flow Compensation for Uniform Response: The innovation of using variable-sized bleed holes (18, 19) to ensure the timing of the pneumatic response is uniform despite variations in the primary air flow (from different sized tracker holes) is a key principle in fluid and pneumatic engineering. This ensures reliable and consistent performance across a range of inputs.

- Integrated Control Logic: The mechanism demonstrates a sophisticated piece of fluidic logic where the switching action (connecting one chamber to atmosphere and the other to suction) simultaneously enables one input path and disables the other, establishing a standard for pneumatic interlocks.

- Instrument Compatibility: The invention contributed significantly to making player pianos backwards-compatible, allowing institutions and consumers to use both older and newer music rolls on a single instrument, maximizing the value and utility of the technology.