Vehicle Wheel (Neal Moore Robinson, No. 1,422,133)

The patent by Neal Moore Robinson of Kansas City, Kansas, describes a novel Vehicle Wheel (Patent No. 1,422,133, 1922). This invention is a “resilient wheel” designed to provide the cushioning effects of a pneumatic (air-filled) tire without the risk of punctures. Robinson’s primary objective was to create a durable, puncture-proof wheel that utilized internal springs to absorb road shocks, making it “easy riding” while maintaining the strength of a solid rubber tire.

Inventor Background: Neal Moore Robinson

Neal Moore Robinson was an African American inventor based in Kansas City during the rapid expansion of the automotive industry. In the 1920s, pneumatic tires were prone to frequent blowouts and punctures on unpaved roads. Robinson’s patent reflects a significant engineering trend of the era: attempting to move the “resilience” of the tire into the hub and spokes of the wheel itself. His design is a sophisticated example of mechanical shock absorption, treating the wheel as a dynamic suspension system.

Key Mechanical & Resilient Systems

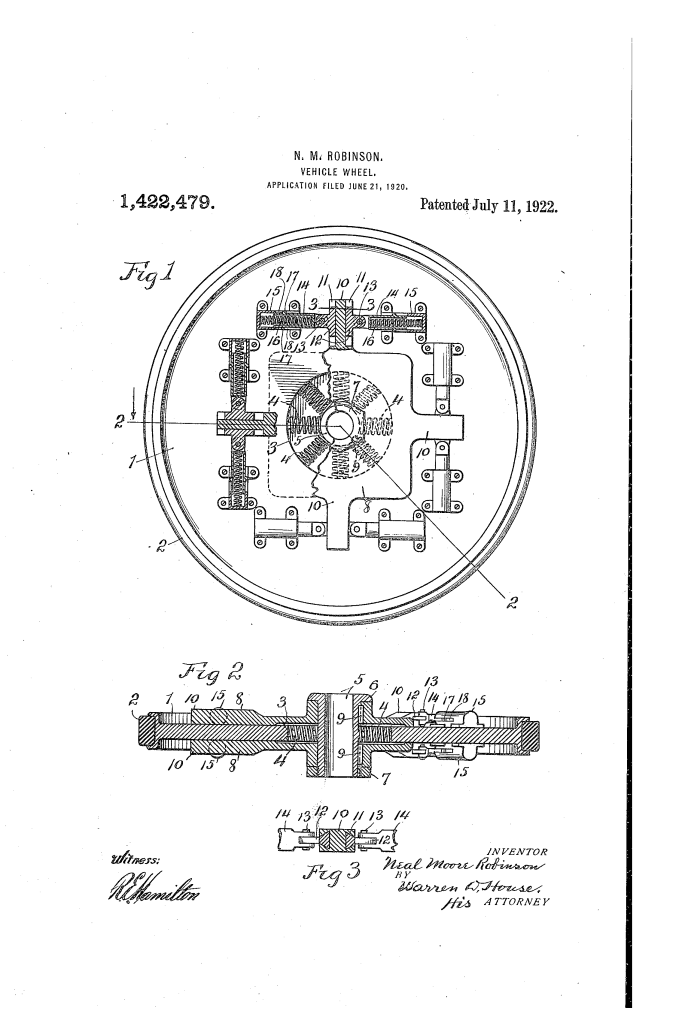

The wheel is composed of a rigid outer body and a floating central hub, connected by a series of radial and tangential springs.

1. The Floating Hub and Radial Springs (3, 4, 5)

- The Body (1): The outer part of the wheel holds a solid rubber tire (2). Unlike a standard wheel, the center is a large opening (3).

- Radial Coil Springs (4): The central hub (5) is suspended within this opening by heavy-duty coil springs. These springs bear the weight of the vehicle and allow the hub to move in all directions within a vertical plane.

- Function: When the wheel hits a bump, the hub “floats” against these springs, absorbing the vertical impact before it reaches the axle.

2. The Driving Members and Dove-Tail Joints (8, 10, 11, 12)

- Driving Members (8): Two plates are keyed to the hub and rotate with it. These plates feature radial arms (10).

- Dove-Tail Grooves (11): Each arm has a longitudinal groove where a slidable member (12) is fitted.

- Function: This allows the hub to move up and down (radially) relative to the wheel body while still maintaining a solid connection to transfer power from the axle to the tire.

3. Tangential Shock Absorption (14, 15, 16)

- Bearing Members (14, 15): The wheel features a secondary set of springs arranged tangentially (perpendicular to the radial arms).

- Sliding Pistons: A tubular member (14) slides inside another (15), which is attached to the wheel body.

- Coil Springs (16): These internal springs resist the rotation of the hub relative to the body.

- Function: These springs act as “torque dampeners.” When the vehicle accelerates or brakes, these springs compress, smoothing out the transfer of energy and protecting the drivetrain from sudden jerks.

Engineering Features and Operational Logic

| Feature | Hazard Addressed | Robinson’s Engineering Solution |

| Solid Tire (2) | Punctures and blowouts. | Uses a solid rubber exterior; resilience is moved to the internal mechanism. |

| Radial Springs (4) | Vertical road shock. | Allows the hub to move independently of the rim in a 360-degree range. |

| Dove-Tail Member (12) | Power loss during flexion. | Ensures the hub and rim remain “locked” in rotation even when the hub is off-center. |

| Slotted Lugs (17, 18) | Part misalignment. | Lugs and slots prevent the bearing members from twisting, ensuring springs stay aligned. |

Significance to Automotive Engineering

Neal Moore Robinson’s vehicle wheel was an ambitious attempt to solve the “pneumatic problem” through pure mechanical physics.

- Internalized Suspension: By placing the suspension inside the wheel, Robinson anticipated modern “in-wheel” motor designs and high-performance shock-absorbing hubs used in specialized industrial vehicles.

- Multi-Directional Flexion: The combination of radial movement (for bumps) and tangential movement (for torque) shows a high level of mechanical sophistication, ensuring the wheel could handle both the weight of the car and the power of the engine simultaneously.

- Sustainability and Durability: His design aimed for a “simple construction and cheap to manufacture” alternative to the expensive and fragile tires of the 1920s, prioritizing long-term reliability for the average driver.