Valve-Gear for Steam-Engines (Robert Leon Campbell, No. 728,364)

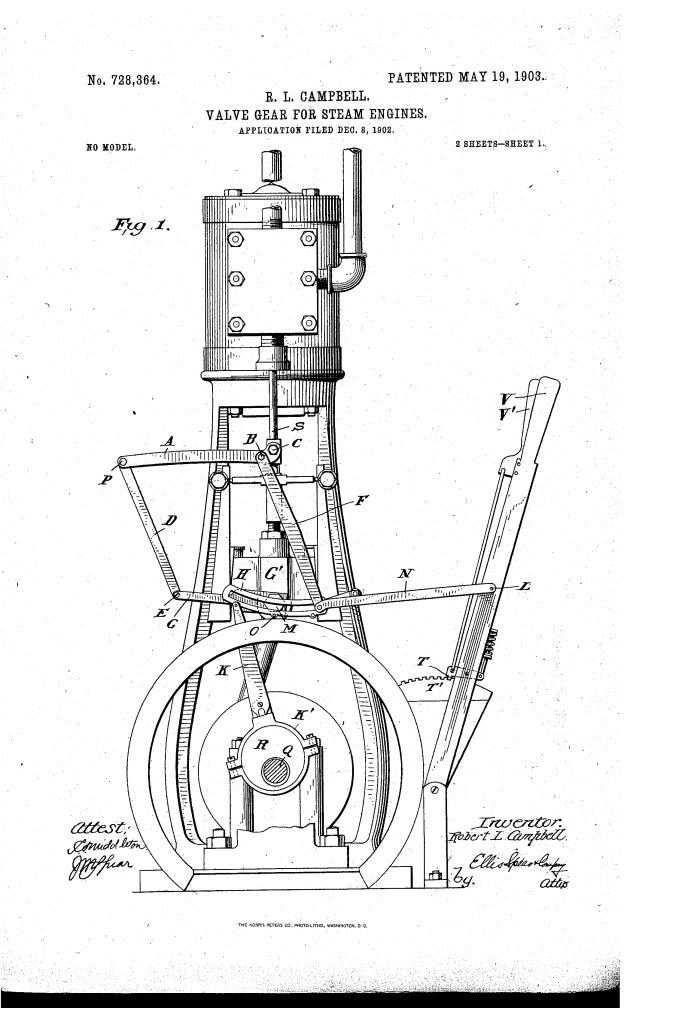

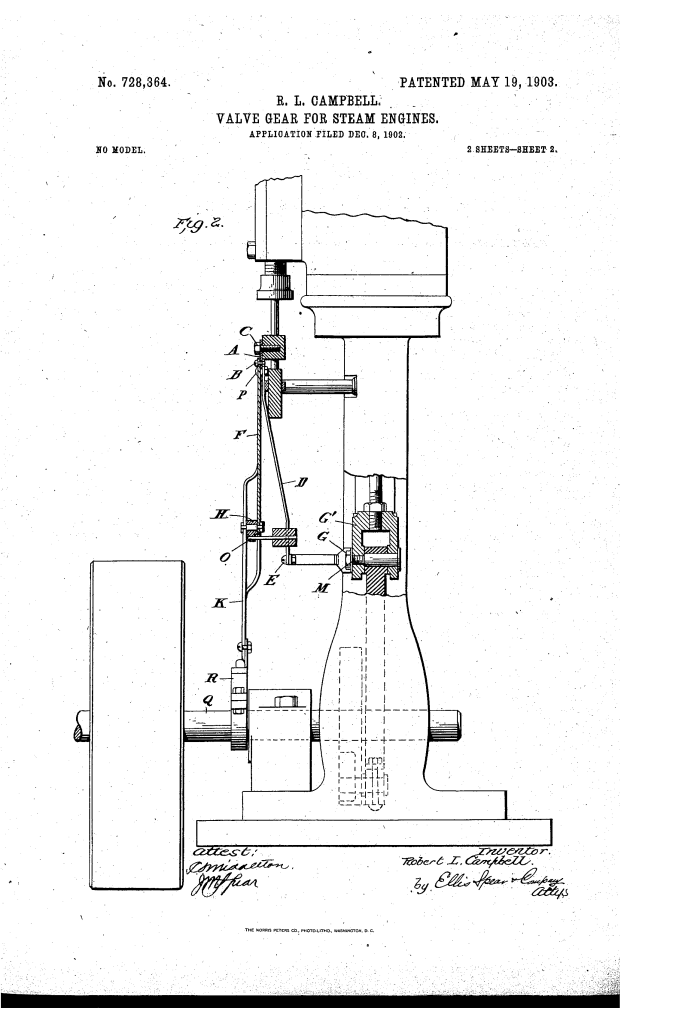

The patent by Robert Leon Campbell of Tuskegee, Alabama, describes certain new and useful Improvements in Valve-Gear for Steam-Engines (Patent No. 728,364, 1903). The invention relates to a reversing valve-gear for stationary, locomotive, and marine engines. The primary objective is to provide an extremely simple and efficient construction that secures all necessary results using only a single eccentric, reducing friction and complexity.

Inventor Background: Robert Leon Campbell

Robert Leon Campbell was an African-American inventor and engineer based in Tuskegee, Alabama. His patent is particularly notable as he assigned one-half interest to Booker T. Washington, the influential educator and founder of the Tuskegee Institute. This connection highlights the Institute’s role in fostering practical technical education and supporting Black innovation in industrial fields, specifically targeting steam engine efficiency which was vital for industry and education.

Invention and Mechanism (Simplified)

The invention is a specialized linkage that uses motion derived from both the main piston (cross-head) and a single rotating eccentric to control the slide valve precisely, allowing for reversal and variable cutoff.

- The Problem: Traditional steam engines (especially for locomotives) often required two eccentrics on the crankshaft to operate the valve gear efficiently and allow for reversing. This added complexity, weight, and friction.

- The Single Eccentric Solution (Key Innovation): Campbell’s system uses a single eccentric (R) set $90^\circ$ from the main crank, but supplements its motion with a direct link to the piston cross-head.

- The Linkage System:

- Rocking Link (H): One end is connected to the single eccentric (R), receiving the main timing motion. A block from rod F slides in this link (H).

- Piston Connection (D & G): A rod (D) connects the cross-head (G’) (which moves with the piston) to the outer end of a lever-arm (A).

- Valve Rod Connection (A & S): The inner end of the lever-arm (A) is pivotally connected to the valve-rod (S).

- Fulcrum Rod (F): A rod (F) connects the lever-arm (A) to the sliding block in the rocking link (H), acting as a shifting fulcrum for lever A.

- Result (Precise Control): The valve’s motion is the result of compounding the simple eccentric throw (from R) with the direct, proportional motion of the piston (from G’). This intricate lever arrangement (A, D, F) overcomes the timing problems inherent in using a single $90^\circ$ eccentric, allowing the valve to open and close the ports at any desired portion of the stroke.

- Reversing: A separate shifting link (N) connected to the fulcrum rod (F) and the shifting-lever (V) allows the operator to control the position of the fulcrum, thereby changing the valve’s timing to reverse the engine’s direction.

Concepts Influenced by This Invention

Campbell’s valve gear influenced subsequent mechanical and hydraulic control systems by pioneering a highly effective compound motion synthesis using minimal inputs.

- Compound Kinematic Synthesis: The most significant influence is the strategy of synthesizing the required complex valve motion by mechanically combining inputs from two different sources (the eccentric/timing input and the cross-head/position input). This principle is used in modern:

- Advanced Linkages: Mechanical and hydraulic systems requiring precise, non-linear control, such as specialized machinery timing and engine mechanisms.

- Minimal Input Efficiency: The goal of achieving all necessary functions (reversing, variable cut-off, and proper timing) with a single eccentric influenced the engineering drive for complexity reduction and part minimization in high-cost, heavy-duty machinery.

- Shifting Fulcrum Control: The use of the rocking link (H) and the shifting link (N) to dynamically change the fulcrum point of the control lever (A) is a sophisticated technique for modulating output from a constant input. This is used in various industrial applications for variable stroke or rate control.