The patent by Brinay Smartt of Nashville, Tennessee, describes a Valve-Gear (Patent No. 935,169, 1909). The fundamental object is to provide a valve-gear that makes it possible to dispense with the eccentrics, the links, and their attachments traditionally used in steam engine valve-gear. The secondary goal is to provide a simple, efficient, and highly durable replacement.

Inventor Background: Brinay Smartt

Brinay Smartt was an African-American inventor and entrepreneur specializing in rail technology and industrial efficiency. He also patented an earlier, more complex Reversing-Valve (No. 799,498) that aimed to simplify the link-motion. This later patent represents his continued effort to strip complexity from steam engine kinematics, making them easier to build, operate, and maintain—a crucial need for widespread industrial adoption.

Invention and Mechanism (Simplified)

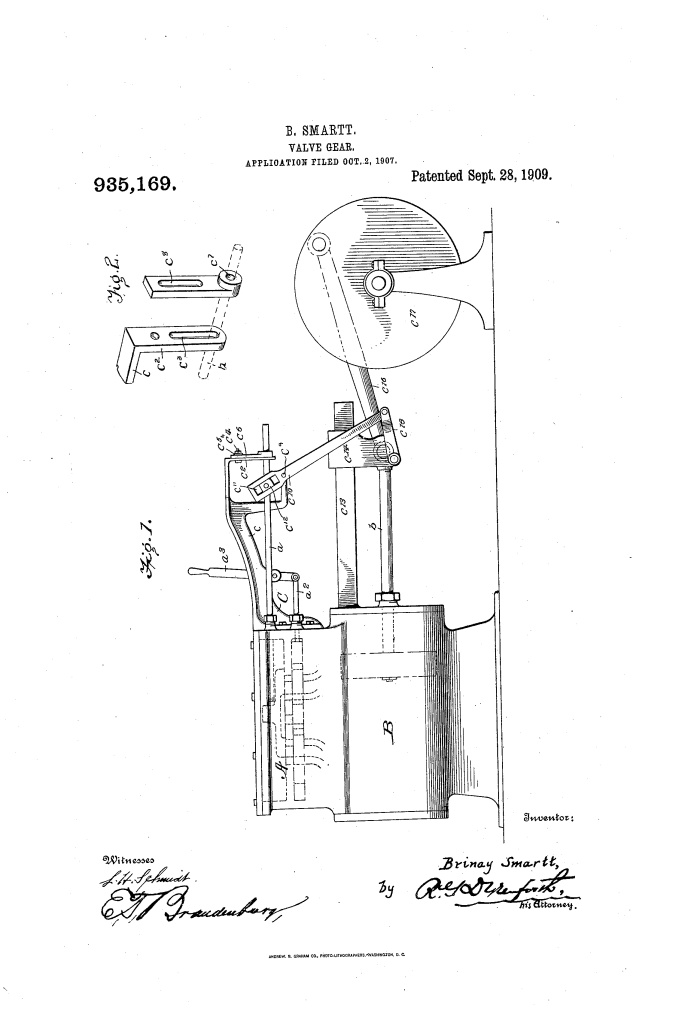

The invention replaces the entire complex system of external eccentric rods and links with a single rocking lever (hanger) that is controlled directly by the engine’s main piston.

- The Problem: Traditional steam engine valve-gear (link motion) required several rotating parts (eccentrics) and numerous heavy, external rods and links to translate crankshaft rotation into the precise, timed motion needed for the steam valve. This system was cumbersome, required extensive maintenance, and consumed significant space.

- Simplified Direct Drive (The Standard C): A rigid standard (C) is attached to the fixed steam valve-box (A). This standard guides the movement.

- Hanger (The Rocking Lever $c^{10}$): A depending hanger ($c^{10}$) is pivotally supported from the standard’s arm ($c$). This hanger swings or rocks back and forth.

- Piston Connection (Key Innovation): The lower end of the rocking hanger ($c^{10}$) is connected by a **link ($c^{18}$) ** to the main piston-rod’s cross-head ($c^{14}$). The cross-head’s motion is also linked to the main driving wheel ($c^{17}$) via rod ($c^{16}$).

- Valve Connection: The upper end of the rocking hanger ($c^{10}$) has a block ($c^{12}$) that is secured to the steam-valve rod ($a$).

- Operation:

- Forward Stroke: The piston moves forward, pushing the cross-head ($c^{14}$) and the link ($c^{18}$) forward.

- Result: This rocking motion of the hanger ($c^{10}$) pulls the valve rod ($a$) forward, moving the steam valve to cover the spent port and uncover the live steam port for the return stroke.

- Efficiency: The system achieves the necessary valve timing by using the engine’s own piston position as a direct input, eliminating the need for complex eccentrics and external links.

Concepts Influenced by This Invention

Smartt’s valve gear influenced subsequent mechanical designs by reinforcing the principle of direct, non-eccentric actuation for reciprocating machinery.

- Non-Eccentric Actuation: The core influence is the successful design strategy of entirely eliminating the eccentric and link motion by using a direct-coupled, swinging lever (hanger $c^{10}$) whose motion is derived from the engine’s own piston rod. This influenced the engineering of simpler, compact valve gears for small and specialized engines.

- Compact, Integrated Design: The system’s achievement of a crucial function (timing the valve) with a minimum number of parts (replacing a dozen pieces with three simplified rods and one hanger) influenced the design philosophy of simple, durable, and space-saving industrial machinery.

- Adjustable Guidance: The inclusion of a slotted arm ($c^{3}$) and adjustable plate ($c^{6}$) to guide the valve stem ($a$) influenced the design of industrial actuators that require precise, field-adjustable guidance to maintain alignment and reduce wear.

- Direct Kinematic Input: The reliance on the piston rod’s cross-head as a primary kinematic input source, rather than the rotating crankshaft, influenced the development of specialized engine designs where valve timing needs to be precisely controlled relative to the piston’s linear position.