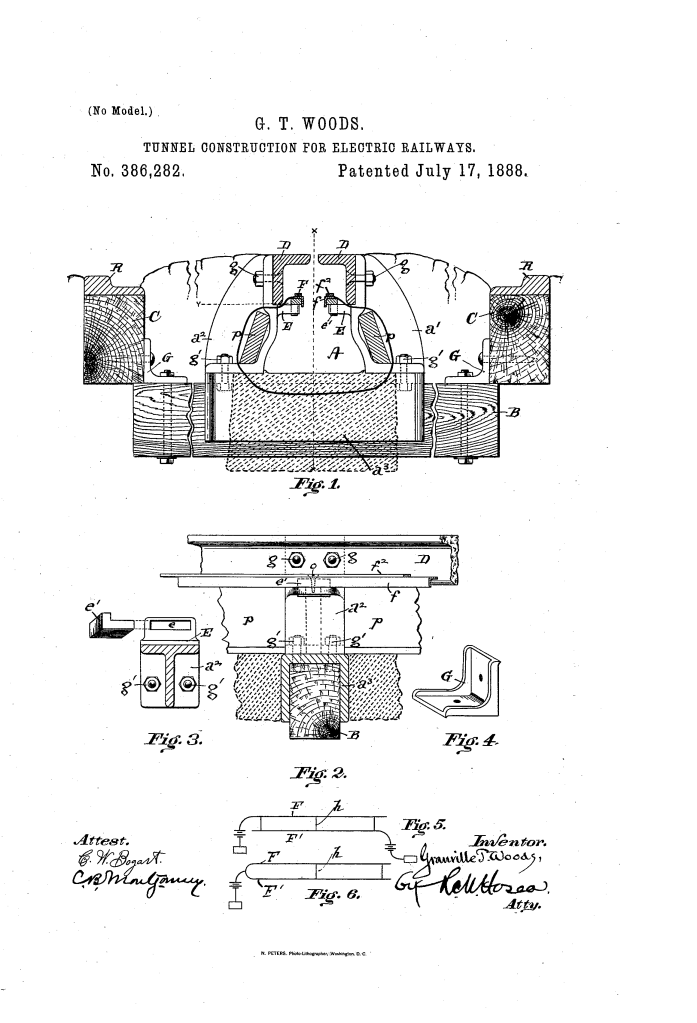

Tunnel Construction for Electric Railways (Granville T. Woods, No. 386,282)

The patent by Granville T. Woods of Cincinnati, Ohio, describes a Tunnel Construction for Electric Railways (Patent No. 386,282, 1888). This invention provides a specialized underground housing (conduit) for the electrical conductors used to power streetcars. Woods’s primary objective was to create an economical and efficient sub-surface system that protected the power lines from the elements and from accidental contact by pedestrians, while allowing a “traveling contact” (plow) from the car to reach the conductors through a narrow slot in the roadway.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910) was a prolific African American inventor known for his contributions to the electrification of the railroad. In the late 1880s, cities were eager to move away from horse-drawn carriages but were wary of dangerous overhead wires. Woods’s “third rail” conduit system offered a safer, underground alternative. This patent showcases his mastery of civil and electrical engineering, specifically addressing the challenges of drainage, insulation, and electrical “leakage” in an urban environment.

Key Mechanical Components & Functions

The system is built around a series of cast-iron yokes that support both the track slot and the electrical power lines.

1. The Tripartite Cast-Iron Yoke (A)

- The Base-Piece (a²): A specialized base designed to fit over and upon a wooden cross-tie (B).

- The Jaw-Pieces (a, a): Two upward-projecting jaws that bolt to the base.

- Function: These jaws maintain the slot-rails (D)—the metal edges of the narrow opening in the street. By making the jaws removable, Woods ensured that the system could be easily repaired without ripping up the entire track.

2. Insulated Brackets and Conductors (E, F)

- Brackets (E): Each jaw has an inner projection or bracket with a vertical hole.

- Insulating Plugs (e): A plug made of wood or non-conductive material is inserted into the bracket.

- The Conductors (F): The conductors are composed of an angle-iron strip (f) for strength, topped with a copper strip (f²) for high electrical conductivity.

- Function: The angle-iron protects the copper from mechanical wear, while the insulating plugs prevent the current from escaping into the iron yoke and the ground.

3. The Drainage and Tunnel Structure

- Tunnel Sides (p): Formed by continuous wooden planks resting against the yokes.

- The Gutter: The bottom of the tunnel is made of concrete, shaped into a continuous gutter.

- Function: This design directs any rainwater that enters through the street slot toward drainage openings at regular intervals, keeping the electrical components dry and functional.

Electrical Strategy: The “Single Polarity” Logic

Woods introduced a specific electrical configuration to increase safety and reliability (Figs. 5 and 6).

- Double Conductors: The system uses two parallel conductors (F, F).

- Same Polarity: Crucially, both conductors exhibit the same polarity (e.g., both are positive).

- Function: This minimizes “leakage” to the ground. If the conductors were opposite polarities in a damp tunnel, the electricity would constantly try to jump between them. By making them the same, Woods ensured a steady, efficient contact for the car’s brush while reducing power waste.

- Ground Return: The circuit is completed by “grounding” the motor to the metal slot-rails or the carrying rails (R).

Improvements Over Previous Conduit Systems

| Feature | Standard 1880s Conduits | Woods’s Tunnel Construction |

| Material Cost | Often used solid copper or expensive alloys. | Uses angle-iron with copper facing for strength and economy. |

| Maintenance | Required extensive excavation for repairs. | Removable jaw-pieces allow for surface-level component access. |

| Electrical Leakage | High; moisture caused “shorts” between poles. | Single-polarity logic and concrete guttering keep the system stable. |

| Reliability | Single contacts often sparked or failed. | Double conductors ensure a constant connection for the traveling brush. |

Significance to Urban Infrastructure

Granville T. Woods’s tunnel construction influenced the development of subway power systems and modern streetcar conduits.

- Sub-Surface Electrification: His design was a precursor to the “third rail” systems used in modern subways, proving that high-voltage power could be safely managed beneath city streets.

- Modular Infrastructure: The use of cast-iron yokes to manage both structural load and electrical delivery is a foundational principle in integrated utility design.

- Drainage Engineering: Woods’s focus on the concrete gutter and water-shedding profiles anticipated the complex civil engineering required for modern underground transit tunnels.

- Redundant Contact: The “double conductor” approach is still reflected in high-reliability industrial power delivery systems, ensuring that a bit of debris on one rail doesn’t stop the vehicle.