Car-Coupling (Andrew Jackson Beard, No. 594,059)

The patent by Andrew Jackson Beard of Eastlake, Alabama, describes an improvement in a Car-Coupling (Patent No. 594,059, 1897). The invention relates to the class of couplers using horizontal jaws and is designed to be simple, cheap, and modular (parts easily replaced). The key object is to provide an automatic coupler where the head and jaw open and close in opposite directions for coupling and uncoupling.

Inventor Background: Andrew Jackson Beard

Andrew Jackson Beard (1849–1921) was an African-American inventor and entrepreneur from Alabama who made several significant contributions to transportation and agriculture.

- Focus on Rail Safety: Beard is most famous for his work in railway safety, particularly the automatic rotary car coupler (patented in 1899), which mechanically linked cars without a person having to go between them—a crucial step in reducing the extremely high rates of death and injury among railway workers in the late 19th century.

- Versatility: His inventions also included a plow design (patented in 1881), demonstrating a broad ingenuity across industrial and agricultural needs.

- This Patent (1897): This earlier coupler patent is part of his focused effort to improve the safety and design of railway couplers leading up to his more famous rotary mechanism. The modular design of this coupler aimed to solve the practical problem of costly repairs by allowing rapid replacement of individual broken parts (head or shank).

Invention and Mechanism

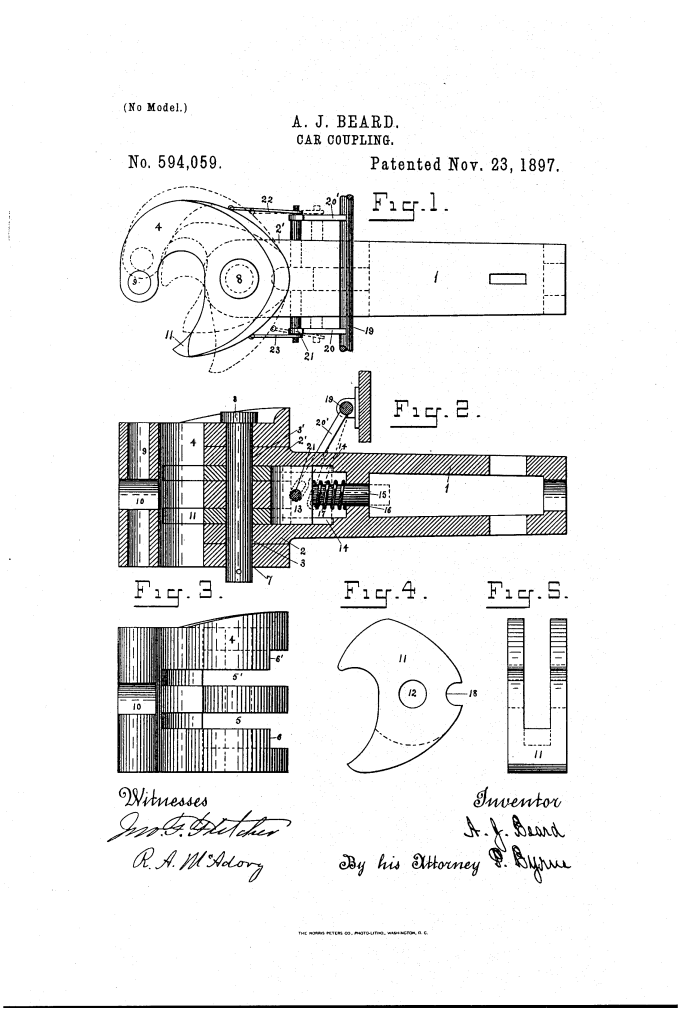

The coupler is an automatic, jaw-type mechanism constructed from separate, pivotally connected components for easy maintenance.

1. Modular Assembly

- Shank (1): The main draw-head shank, designed to attach to the car. It has forward-projecting lugs (2, 2′) with pin-holes.

- Head (4): The front portion of the coupler, having slots (6) to receive the shank lugs and also slots (5) to receive the jaw’s tail-wings.

- Jaw (11): The side jaw component.

- Single Pivot Pin (8): A single pin passes through all three components (shank lugs, head, and jaw pin-hole 12), pivotally connecting the entire assembly.

- Function: This modular construction allows a broken head (4) or jaw (11) to be readily attached to replace a broken part by simply knocking out and replacing the single pivot pin (8).

2. Locking and Automatic Action

- Head-Lock (13): A sliding metallic lock housed in grooves in the shank lugs. A coiled spring (17) keeps the lock pressed forward, where it engages a concave recess (18) provided in the head and side jaw.

- Function (Coupling): When two cars come together, the opposing draw-heads push the lock (13) back. Once the heads align, the spring (17) forces the lock forward into the recess (18), locking the jaws and head together automatically.

- Uncoupling Mechanism:

- Operating-Rod (19): Extends across the end of the car.

- Linkage: The operating-rod connects via levers (20, 20′) and a transverse bar (21) to the locking device (13). Rods (22, 23) connect the lock to the head and jaw.

- Function: Turning the operating-rod (19) simultaneously withdraws the lock (13) and operates the connecting rods (22, 23) to cause the head and jaw to open and close in opposite directions (as shown by dotted lines in Fig. 1), allowing the draw-heads to come apart and uncouple the cars.

Concepts Influenced by This Invention

Beard’s coupler influenced subsequent mechanical designs by pioneering modular components for high-stress applications and integrated, dual-action linkage for operation.

- Modular Components for Repair: The concept of constructing a high-stress component (like a coupler head) from separate parts joined by a single, accessible pin for rapid replacement influenced the design of industrial machinery and vehicle components that must be quickly repaired or maintained in the field.

- Integrated Dual-Action Linkage: The most direct influence is the use of a single lever/rod (19) to perform two simultaneous, distinct actions—unlatching (withdrawing lock 13) and articulating (opening the jaw 11). This integration of control is a key feature in automated machinery and industrial valves that must perform a sequenced operation from a single input.

- Safety Automation: As part of the wave of late 19th-century automatic coupler patents, this design contributed to the engineering base that led to the universal adoption of automatic couplers, eliminating the need for workers to physically enter the space between cars (as required by the older link-and-pin system).