🛤️ Tie-Plate (Ned E. Barnes, No. 1,180,366)

The patent by Ned E. Barnes of Houston, Texas, describes an improved Tie-Plate (Patent No. 1,180,366, 1916). This invention is a critical piece of railway hardware designed to sit between a steel rail and a wooden tie. Barnes’s primary goal was to solve three common maintenance issues of early 20th-century railroads: the “wearing” or cutting of the rail into the wooden tie, the “spreading” of rails (losing gauge), and the “overturning” of rails under the heavy lateral pressure of passing locomotives.

Inventor Background: Ned E. Barnes

Ned E. Barnes was an African American inventor and businessman based in Houston, Texas. In 1915, he partnered with B. Edmond to patent an automatic film mover, but this 1916 patent shows his expertise in heavy industrial engineering. Railway technology was the backbone of American commerce at the time, and the transition to heavier, faster trains put immense strain on tracks. Barnes’s tie-plate was a robust, mechanical response to these structural demands. He successfully assigned a majority interest in the patent to W. G. Twyman, indicating the commercial viability of his design in the Texas railway market.

Invention and Mechanism (Simplified)

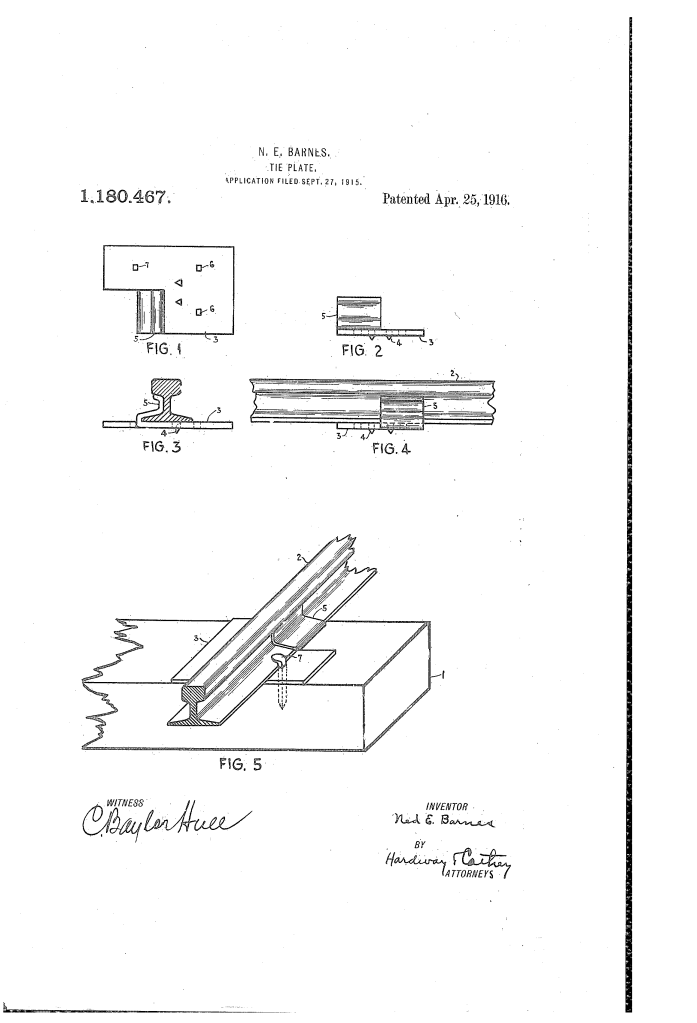

The device is a specially forged metal plate that acts as a cradle and a brace for the rail.

1. The Seat and Teeth (3, 4)

- The Seat: The plate (3) forms a flat, durable seat that receives the base of the rail (2). This distributes the weight of the train over a larger area of the tie (1), preventing the rail from acting like a knife and cutting into the wood.

- Anchor Teeth (4): The underside of the plate features projecting teeth (4).

- Function: These teeth bite into the wooden tie before the spikes are even driven. This keeps the plate perfectly positioned during installation and prevents “creep” (horizontal shifting) during the high-vibration environment of a passing train.

2. The Integrated Bracing Knuckle (5) (Key Innovation)

The most distinctive feature of Barnes’s design is the outer edge of the plate, which is divided or “bifurcated.”

- Upturned Section: One section of the outer edge is bent upward to form a knuckle (5).

- Contour Bracing: This knuckle is shaped to conform exactly to the outer web and the “ball” (head) of the rail.

- Function: Standard tie-plates only held the bottom flange of the rail. Barnes’s plate acts as an external brace for the entire side of the rail. When a train rounds a curve, the lateral force tries to “overturn” the rail; this knuckle physically blocks that movement, keeping the rail upright and perfectly spaced.

3. Spike Orifices (6, 7)

- Configuration: The plate features three orifices—two on the inner side and one on the outer side.

- Securement: Standard railway spikes (6, 7) pass through the plate and into the tie.

- Function: The enlarged heads of the spikes overlap the edges of the rail base, clamping the rail, the plate, and the tie into a single, rigid unit.

Improvements Over Existing Track Hardware

| Feature | Standard 1910s Tie-Plates | Barnes’s Tie-Plate |

| Lateral Stability | Relied entirely on the friction of the spikes. | Integrated knuckle (5) provides mechanical bracing against the rail web. |

| Rail Preservation | Rails could still tilt or “roll” slightly. | Contour-fitting brace supports the rail “ball,” preventing overturning. |

| Installation | Required manual alignment during spiking. | Integral teeth (4) lock the plate to the tie automatically. |

| Tie Longevity | Only protected against vertical crushing. | Prevents spikes from widening their holes by resisting lateral spreading. |

Significance to Civil Engineering

Ned E. Barnes’s tie-plate influenced the development of heavy-haul railway infrastructure and structural fasteners.

- The Rigid-Track Principle: Barnes’s design moved the industry away from “floating” rails toward a more rigid, integrated track structure. This was essential as locomotive weights increased in the early 20th century.

- Bifurcated Forging: The method of “dividing” a single metal plate to serve two functions (a base seat and a vertical brace) is a foundational principle in metal stamping and forging for structural components.

- Gauge Maintenance: By providing a physical barrier (the knuckle) against rail spreading, Barnes helped maintain the “gauge” (the distance between two rails), which is the most critical safety dimension in railroading.

- Modern Rail Anchors: The logic of Barnes’s integrated brace is seen today in specialized “rail anchors” and high-performance “elastic fasteners” used on high-speed rail lines globally.