Supporting-Bracket (Samuel R. Scottron, No. 505,008)

The patent by Samuel R. Scottron of Brooklyn, New York, describes an improved, vertically adjustable Supporting-Bracket designed to hold shelves or other articles without damaging the supporting post. The invention’s core principle is utilizing the weight of the supported object to automatically tighten the bracket’s grip on its vertical support.

Invention and Mechanism

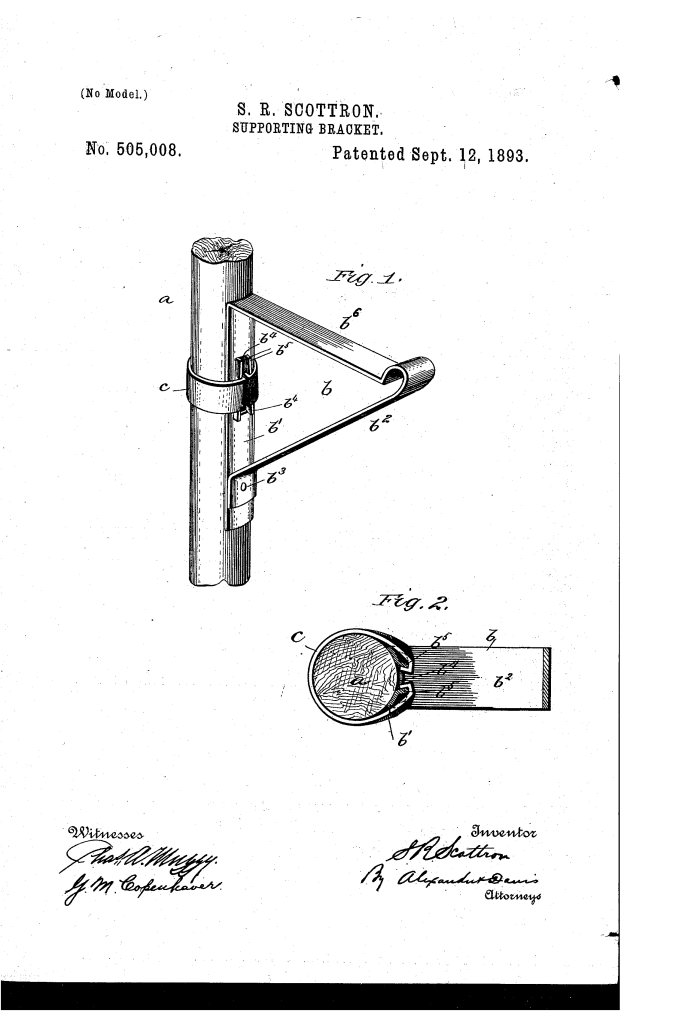

The bracket is an ingenious friction-locking system composed of two main parts:

- Triangular Bracket (b):

- Formed from a single band of metal bent into an open triangle.

- It has a vertical part (b′), a horizontal part (b′′), and an oblique part (b′′′), riveted together at b4.

- The vertical part (b′) is concave to fit closely against the supporting pole (a) and prevent lateral shifting.

- Wedge-Shaped Slot (b5): A vertical slot is cut into the vertical part (b′). The sides of this slot converge upwardly and are bent outward to form oblique flanges (b6).

- Securing Band (c):

- A thin, flexible band of metal that embraces the support (a) and partially embraces the vertical bar (b′) of the bracket.

- The ends of the band are bent down over the converging flanges (b6) in the wedge-shaped slot and terminate before reaching the support.

- Operation (The Clamping Principle):

- Clamping: When a shelf or object is placed on the horizontal part (b′′) of the bracket, the weight exerts a downward force. Because the band is routed through the upwardly converging wedge-shaped slot, the downward pull on the bracket forces the ends of the flexible band (c) toward each other. This tightens the band around the pole (a) with increased friction.

- Adjustment: To loosen the grip for adjustment or removal, one simply needs to raise the bracket slightly while holding the band still. This releases the tension, allowing the band to expand and the bracket to slide vertically.

- Key Advantage: The design obviates the need for nails, screws, etc., preventing the weakening and disfigurement of the support.

Historical Significance and the Inventor

Samuel R. Scottron’s patent, granted in 1893, is a notable example of utility-focused invention, particularly within the context of African-American inventors in the late 19th century.

- Practical Design: Scottron’s invention addressed a common household need: easily adjustable shelving without permanent installation damage. This focus on domestic utility and efficiency was a hallmark of the era’s patent activity.

- The Inventor (Samuel R. Scottron): Samuel Raymond Scottron (1843–1908) was a prominent African-American inventor, businessman, and civic leader in Brooklyn. He was known for several practical inventions, including an ornamental cabinet used for storage. His work demonstrates the ingenuity of Black inventors in solving everyday problems despite the systemic barriers they faced. Scottron was also involved in the development of the electrical sector and was a noted abolitionist and member of the New York African Society for Mutual Relief.

- Friction Lock Innovation: The patent’s significance lies in its elegant use of a wedge-and-lever principle (the downward force on the bracket acting as the lever against the wedge-shaped slot) to convert a static load (the shelf weight) into a dynamic clamping force (friction). This was a mechanically clever solution to the problem of non-destructive load-bearing support.

Relation to Current Items

The core mechanical principle of Scottron’s bracket—using the load to generate the clamping force—is highly relevant to modern temporary and adjustable supports:

- Tension Rods and Curtain Rods: The over-arching principle is found in modern tension rods (like those used for shower curtains or closet organization) which use rotation and friction to generate a force that locks them in place against two parallel surfaces.

- Temporary Clamping and Tool-less Shelving: The design is an early precursor to various cam-lever clamps and quick-release mechanisms used in modern adjustable shelving systems, photography light stands, and temporary fixture supports. These mechanisms allow for rapid adjustment without the use of permanent fasteners.

- Gravity Locks: Scottron’s bracket employs a “gravity-assisted” or “load-sensitive” lock. This concept is fundamental to safety mechanisms in heavy equipment, such as self-locking hitches or certain types of ladder stabilizers, where the force exerted by the load or gravity acts to secure the apparatus.