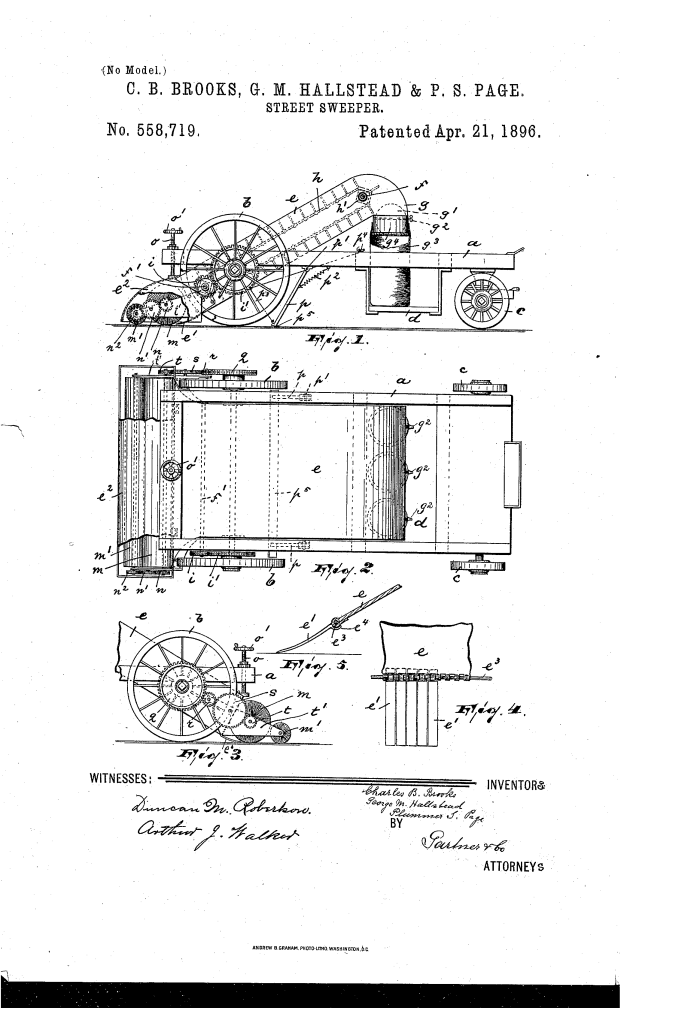

Street-Sweeper (Charles E. Brooks, George M. Hallstead & Plummer S. Page, No. 558,719)

The patent by Charles E. Brooks, George M. Hallstead, and Plummer S. Page describes an improved Street Sweeper and Cleaner (Patent No. 558,719, 1896). This invention is an improvement on Brooks’s previous sweeper design (Serial No. 547,455) and focuses on enhancing efficiency, durability, and most critically, preventing the flying around of dust and dirt during sweeping.

Invention and Mechanism

The machine is a drive-wheel-powered sweeper integrating a multi-stage brush system, a hinged elevator, and a sectional refuse pan.

1. Sweeping Mechanism (Dual Brushes)

- Main Revolving Brush (): The primary brush, mounted in a bracket-frame (

) at the inlet of the elevator casing, receives motion from the rear axle via a gear train and revolves in a direction opposite to the truck wheels.

- Auxiliary Brush (): A smaller revolving brush arranged parallel and in rear of the main brush (

). It receives motion from the main brush’s shaft and revolves in the same direction as the main brush.

- Function: Any dirt missed by the main brush (

) is taken up by the auxiliary brush (

) and discharged back onto the main brush, which then discharges it onto the sectional pan (

). This dual-brush system ensures a more thorough sweep.

- Function: Any dirt missed by the main brush (

2. Refuse Collection and Dust Control

- Sectional Pan (): A pan pivoted to the underside of the elevator casing, consisting of a series of narrow strips (

).

- Function: The sectional nature allows the pan to articulate to the street surface better, while catching the refuse from the brushes.

- Elevator Casing () and Bucket-Chain (): The inclined casing is fulcrumed on the rear axle and houses the endless bucket-chain, which scoops refuse from the pan (

).

- Collection: Refuse is carried up the casing, through a channel (

), and into a series of downwardly-extending hoppers () where removable bags are attached. Dampers (

) on the hoppers can be closed during bag changes to maintain dust containment.

- Dust Containment: The hood or casing () covers both brushes (

) and the pan, and the sealed bag-hopper system is intended to fully prevent dust from escaping during operation.

3. Specialty Scraper

- Spring-Controlled Scraper (): A separate, substantially knife-edged scraper secured to downwardly-extending arms (

) mounted on a rod (19) beneath the truck. It is normally held by spiral springs ().

- Function: This scraper is designed to be lowered (via a cord

) to scrape smooth pavements (like asphalt), for which the brushes might be less effective.

- Function: This scraper is designed to be lowered (via a cord

4. Height Adjustment

- The elevator-casing (

), brush hood (

), and brushes (

) can be raised and lowered simultaneously by an elevator screw (

) with a hand-wheel (

).

Historical Significance and the Inventors

This 1896 patent represents a significant advancement in the technological efforts to solve the public health and logistical crisis of urban waste in the late 19th century.

- Addressing Dust (The Primary Problem): The invention’s explicit goal of “fully avoid[ing] the flying around of dust, dirt, &c.” is paramount. The dual-brush system, sealed casing, sectional pan, and damped hoppers were all designed to overcome the notorious dust pollution caused by earlier mechanical sweepers.

- Multi-Stage Cleaning: The use of multiple parallel brushes of different sizes (

and

) to ensure no dirt is missed is a critical design step toward maximizing the efficiency of the sweep before the debris is elevated.

- The Inventors: Charles E. Brooks and his partners, George M. Hallstead and Plummer S. Page (from Scranton, PA), were responding to the acute need for better sanitation infrastructure in growing industrial cities.

Concepts Influenced by This Invention

Brooks and his partners’ design influenced subsequent street-cleaning technology by establishing the standards for multi-stage operation and debris containment.

- Multi-Stage Sweeping Heads: The most direct influence is the use of two or more parallel brushes of varying sizes to achieve a more thorough sweep. This concept is foundational to modern tandem-sweeping units in most large street sweepers , where a smaller gutter brush precedes a main cylindrical broom.

- Debris Containment and Airflow Management: The system of a sealed hood () over the brush and gasketed hoppers with internal dampers () influenced the development of modern vacuum-assisted and regenerative air sweepers , where the emphasis shifts to managing the air stream and containing dust within the machine structure.

- Sectional/Articulating Ground Engagement: The use of a sectional pan () to articulate with the uneven pavement influenced the design of modern articulating skid plates and flexible vacuum shoes used on sweepers and industrial vacuums to maintain close contact with irregular surfaces.

- Specialized Attachments (Scraper): The inclusion of an independent, spring-controlled scraper (), deployable for specific tasks (like hard asphalt), influenced the design philosophy of modern municipal equipment, which often integrates specialized, interchangeable tools (e.g., plows, scrapers, water jets) onto a single chassis.