Street-Car Fender (Matthew A. Cherry, No. 531,908)

The patent by Matthew A. Cherry of Washington, D.C., describes an improved Street-Car Fender designed to provide an absolute safeguard against injury to a person struck by a moving streetcar or vehicle. The invention emphasizes simplicity, strength, durability, yieldingness (cushioning), and convenience of application, especially for cars operating in trains.

Invention and Mechanism

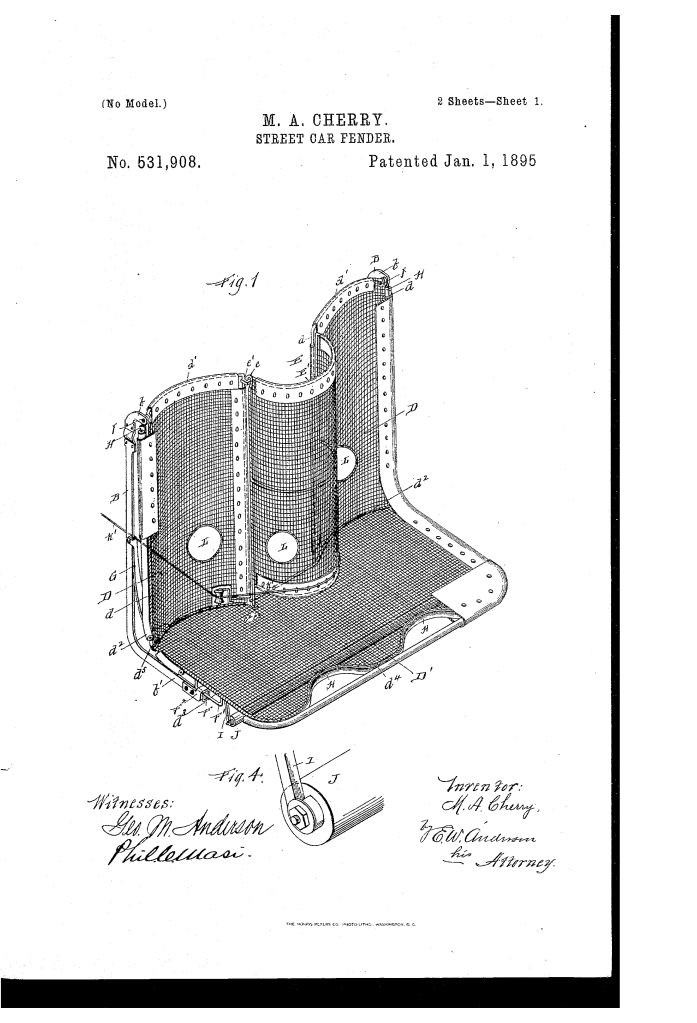

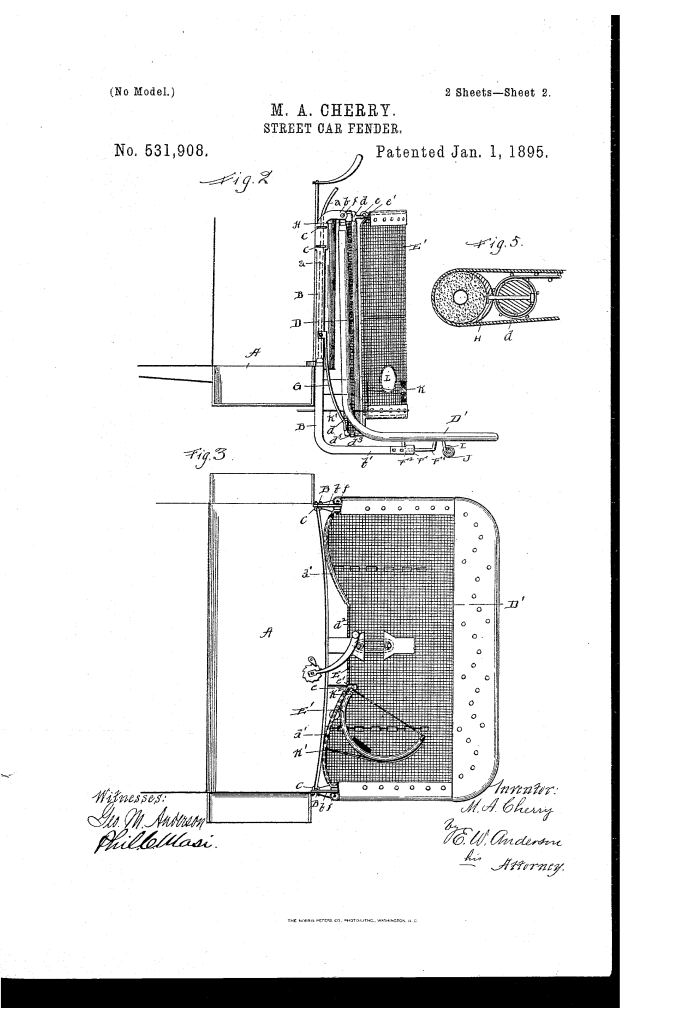

The fender is a complex, cushioned, hinged frame designed to both absorb impact and scoop up a person.

1. Frame and Mounting

- Main Supports (B, B): Rigid metal bars secured to the car frame (posts c) via clips (C). They have upper (b) and lower (b′) forwardly projecting arms.

- Fender Frame (D, D’): A rigid, right-angled frame, typically made of rods and netting, having a vertical portion (D) and a horizontal platform portion (D’).

- Pivotal and Sliding Connection:

- The upper portion is pivotally attached to the upper arms (b) by bolts (f), allowing the fender to swing.

- The horizontal platform portion has a sliding connection with the lower arms (b′), allowing the fender to move backward upon impact.

- Springs (G): Secured to the supports (B, B), these springs bear against the vertical portion (D) of the fender frame.

- Function: Upon striking an object, the fender swings backward against the pressure of these springs, absorbing the impact and providing yieldingness.

2. Safety and Yielding Features

- Yielding Edge Guard: Running around the entire outside of the frame (except the top) is a strip (H) with a concave outer face, which serves as a seat for a hollow rubber tube of considerable diameter.

- Function: This rubber tube acts as a guard to prevent the rigid frame from striking the person, cushioning the initial contact.

- Sinuous Front Rod (d4): The forward transverse rod (d4) is sinuous (wavy), having forward and backward bends.

- Function: When struck, the rubber guard can yield into the backward bends. The forward bends at the sides are intended to prevent the body from being thrown off to one side.

- Flexible Binding (H′): All rods of the fender and gate frames are covered by a thick, yielding binding of considerable width to prevent injury to a person thrown against them.

3. Scoop and Roller

- Under Bearing Roller (J): A transverse roller hung in lugs (I) beneath the forward platform portion (D’).

- Function: The force of the impact causes the fender to swing back, and the weight of the object (person) received by the platform brings the roller (J) into contact with the track or pavement. This likely helps scoop the person onto the platform and reduces drag.

4. Gate for Couplings

- Opening and Gate (E,E′): The vertical portion (D) has a central vertical opening (E) closed by a semi-cylindrical (convex) gate (E′), which is preferably made of wire netting.

- Function: This gate makes the fender specially adapted for cars made up in trains. The gate can be opened using cords (K′,K2) to admit the coupling link between cars.

Historical Significance and the Inventor

Matthew A. Cherry’s 1895 patent is a significant reflection of the urgent public safety crisis caused by the rapid, widespread deployment of electric streetcars (trolleys) in American cities.

- Public Safety Crisis: By the 1890s, streetcars moved much faster and quieter than horse-drawn vehicles, leading to a dramatic increase in accidents, injuries, and fatalities. The public demanded solutions. Cherry’s fender is part of a wave of inventions aimed at creating a functional safety device that could reliably catch and protect a person rather than simply pushing them aside or crushing them.

- Engineering for Impact: The emphasis on yieldingness, springs (G), rubber guards, and the sinuous bar (d4) demonstrates an attempt to engineer a solution based on impact absorption and deflection, moving beyond simple rigid cowcatchers.

- Addressing Logistics: The inclusion of the gate (E′) for coupling links addresses a specific practical need for transit companies: a safety device that does not interfere with the essential operation of linking multiple cars into a train, which was common on cable and electric lines.

- The Inventor (Matthew A. Cherry): Cherry, residing in Washington, D.C., was working in the nation’s capital, which was an early adopter of advanced streetcar systems. His patent reflects the high demand for safety innovations in a rapidly urbanizing environment.

Relation to Current Items

Cherry’s fender utilizes concepts that are still essential in modern vehicle safety and rail equipment:

- Crash Absorption Zones: The use of springs (G) and a yielding frame to absorb impact is the foundational concept behind modern crumple zones and deformable energy absorption units used in automobiles and passenger train crash buffers.

- Obstacle Deflection and Guidance: The sinuous frame rod (d4) designed to guide a struck object and prevent lateral deflection is related to modern rail cowcatcher/pilot designs which are heavily contoured to deflect objects (or bodies) away from the wheels and underneath the frame.

- Active/Deployable Fenders: While Cherry’s was passively hinged, its functionality is ancestral to modern pilot plow or obstacle deflector systems on freight trains and some light rail, and also conceptually related to the mechanisms of safety devices that may momentarily drop or deploy upon sensor detection of an object.

- Modular Attachments: The design that allows the safety equipment to be quickly detached (via bolts f) and integrates an operational component (the gate) is a principle of modern modular equipment attachments in the rail industry, ensuring that essential safety gear doesn’t permanently complicate maintenance or multi-unit coupling.