Steam-Table (George W. Kelley, No. 592,591)

The patent by George W. Kelley of Norfolk, Virginia, describes an improvement in a Steam-Table (Patent No. 592,591, 1897) designed for keeping viands warm in hotels, restaurants, and dining-rooms. The object is to provide a simple, convenient, and effective multi-chamber device that uses steam to keep food hot and moist.

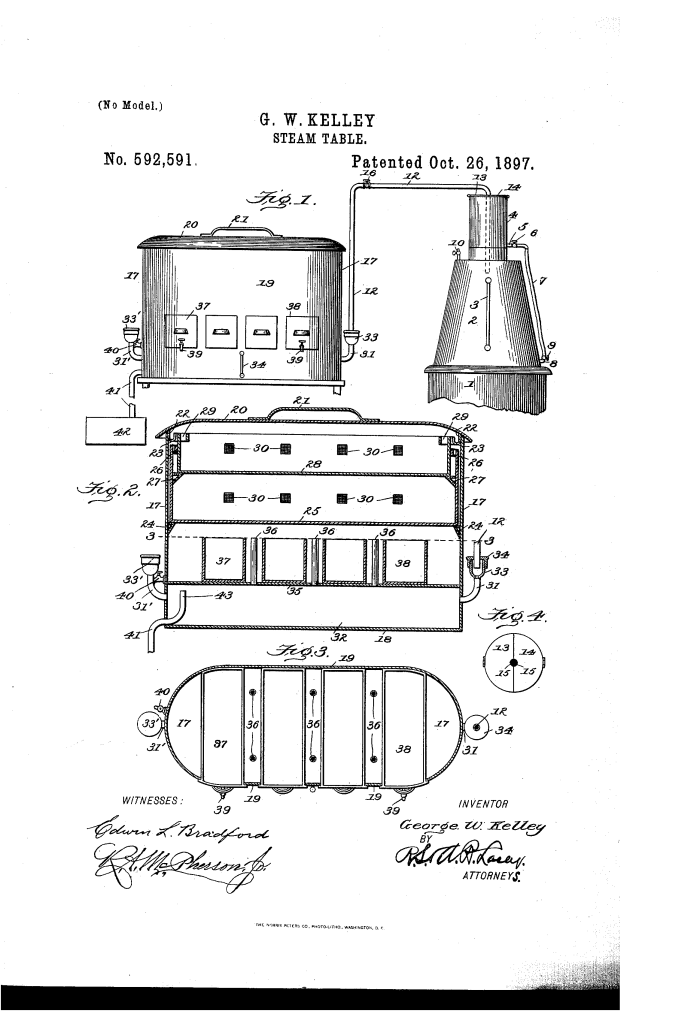

Invention and Mechanism

The device is a tiered, modular steam unit that connects to an external heat source (stove or range).

1. Steam Generation and Water Feed

- Heater (2): A conical cylindrical boiler (or heater) designed to sit on top of an ordinary stove or range (1). It has a vertical glass water-gage (3).

- Feed-Water System: A cylindrical feed-water tank (4) sits on top of the heater (2). It connects to the heater via a flexible pipe (7) and inlet pipe (8).

- Function: Hot water from a discharge pipe (41) can be collected and emptied into the tank (4). The steam-supply pipe (12) passes vertically through this tank (4), maintaining the feed-water at a proper temperature before it’s fed back into the boiler (2).

2. Three-Chamber Steam Table (Key Innovation)

The table structure is composed of three distinct horizontal chambers stacked above the steam-supply chamber (Heater 2):

- Steam-Supply Chamber (32): This is the hot-water space inside the heater (2).

- Steaming-Chamber (35): Located immediately above the steam-supply chamber, this chamber has a diaphragm (35) at its base. Steam passes from the hot-water space (32) up through vertical tubes (36) fixed in the diaphragm.

- Food Receptacles: This chamber houses horizontal, rectangular drawers (37, 38) that slide on the diaphragm. The outer drawers (38) have faucets (39) for serving hot coffee or tea.

- Warming-Chamber (17): Located above the steaming-chamber (35). Its bottom is the top/cover of the steaming-chamber.

- Tiered Trays: This chamber contains multiple removable trays (25 and 28), which are supported by internal angle-brackets (24, 27). The trays hold food like roast joints, bread, and rolls.

3. Moisture Control (The Moist/Dry Balance)

- Perforated Walls: The walls of the food-holding trays (25, 28) have a series of orifices (30) protected by a fine-wire-gauze diaphragm.

- Function: This wire-gauze is intended to cause the saturated steam to condense on the gauze itself, only permitting a small amount of comparatively dry steam to enter the trays. This supplies just enough moisture to replace evaporation and keep the food palatable, preventing it from getting overly soggy.

Historical Significance and the Inventor

George W. Kelley’s 1897 patent reflects the rapid growth of the hospitality and service industries in the late 19th century, particularly the standardization of restaurant and hotel dining.

- Commercial Food Service: The invention provided a dedicated, high-capacity appliance for the preparation and holding of food. This type of equipment was essential for the efficiency of large-scale buffets, cafeterias, and high-volume dining rooms, keeping multiple courses hot simultaneously.

- Integrated System: The significance lies in the integration of the heating, water management, and multi-chamber holding into a single appliance. The design solved the logistical problem of constantly monitoring and replenishing the water supply with its ingenious pre-heating feed-water tank (4).

- The Inventor (George W. Kelley): Kelley, residing in Norfolk, Virginia, contributed to the necessary commercial infrastructure of the modern food service industry.

Concepts Influenced by This Invention

Kelley’s steam-table design utilizes principles of thermal and fluid management that are standard in modern commercial kitchens and HVAC systems.

- Tiered Thermal Zones: The use of stacked chambers (steaming chamber 35 and warming chamber 17), each receiving controlled heat from the same source, is the core concept of modern commercial holding cabinets and combi ovens that provide different levels of heat or humidity for different food types (e.g., higher moisture at the bottom, drier heat at the top).

- Wire Gauze for Steam Conditioning: The idea of using a fine wire gauze or mesh (30) at the steam inlet to facilitate condensation and moisture control is an early example of steam conditioning. This principle is used in modern industrial processes (and some combi ovens) that require specific levels of humidity, utilizing demister pads or mesh filters to remove excess moisture from saturated steam.

- Heat Recovery/Pre-Heating: The design that routes the steam-supply pipe (12) through the feed-water tank (4) to pre-heat the water before it returns to the boiler is a clear example of a heat recovery system. This principle is fundamental to modern high-efficiency HVAC, boiler, and water heating systems to conserve energy.

- Modular/Sectional Food Wells: The use of multiple, removable, and distinct food receptacles (drawers 37, 38 and trays 25, 28) within a common heated chamber is the standard design for all modern steam tables and buffet hot wells.