Steam-Gage (John O’Connor and Collatinus A. Turner, No. 566,613)

The patent by John O’Connor and Collatinus A. Turner describes an improved Steam-Gage (Patent No. 566,613, 1896). The invention integrates a standard steam pressure indicator with electrical systems for alarming excessive pressure changes and automatically controlling the boiler draft to prevent dangerous overpressure.

Invention and Mechanism

The device transforms a conventional Bourdon tube pressure gauge into a sophisticated, multi-functional safety and control unit.

1. Steam Pressure Readout

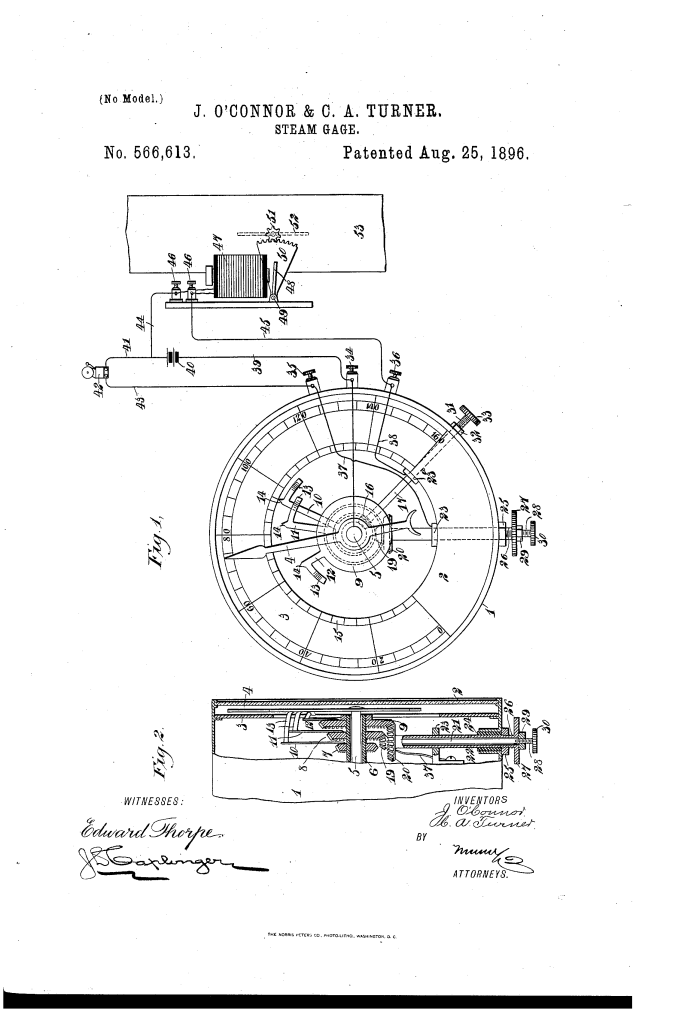

- Casing (1), Scale (3), and Pointer (4): The core components of a standard steam pressure gauge, where the pointer (or “index”) is actuated by pressure devices inside the casing.

2. Electrical Contact System (The Integration)

- Adjustable Contact Fingers (10, 11, 12): Multiple index fingers are mounted on insulated sleeves/shafts (6) within the gauge face. These fingers can be manually adjusted (via gear-and-shaft mechanisms 17, 21, 22) to set their position at any desired pressure point on the scale (3).

- The Pointer as a Terminal: The pointer (4) acts as the moving terminal in the electrical circuit. When the pressure reaches the preset limit, the pointer sweeps across the scale and makes contact with the stationary spring arm (13) on one of the adjustable fingers, thereby closing an electric circuit.

3. Dual Safety Functions (Key Innovations)

- Alarm Circuit (Fingers 11 & 12): Two fingers (11, 12) are typically set as the high and low pressure limits. When the pointer contacts either one, it closes a circuit connected to a battery (40) and a bell (42), sounding an alarm to warn the operator.

- Automatic Control Circuit (Finger 10): A third finger (10) is set slightly beyond the high-pressure alarm point. When the pointer contacts this finger, it closes a separate circuit containing an electromagnet (47).

- Actuation: The energized magnet (47) pulls an armature (48), which uses a segment-rack (50) and pinion (51) to pivotally turn a damper (52) in the boiler’s flue or chimney (53).

- Function: Closing the damper reduces the draft, causing the fire to cool, thereby lowering the steam pressure and automatically correcting the overpressure condition.

Historical Significance and the Inventors

This 1896 patent is a significant step in the history of industrial automation and safety.

- Integrated Safety System: It moved beyond passive safety (like a spring-loaded relief valve) by creating an active, visible, and remotely audible safety system. The alarm gave warning, and the automatic damper provided a crucial second layer of defense against catastrophic boiler failure.

- Early Transducer Design: The invention cleverly repurposed the mechanical energy and motion of the pointer—the indicator of the measured variable—into a reliable electrical signal, making the standard gauge an effective sensor and control trigger.

- The Inventors: John O’Connor and Collatinus A. Turner solved a critical problem for high-pressure steam operations by creating a system that could monitor conditions and initiate automatic corrective action, reducing the risk dependent solely on human intervention.

Concepts Influenced by This Invention

The O’Connor and Turner Steam-Gage influenced the design and engineering of modern industrial control systems by pioneering the direct integration of sensor, alarm, and actuator functions.

- Integrated Sensor/Alarm/Control Platforms: The primary influence is the conceptual merging of the readout instrument and the control system. This led directly to modern Process Control Systems and SCADA (Supervisory Control and Data Acquisition) interfaces, where the same device or screen provides the pressure reading, displays the alarm set points, and initiates automatic corrective actions (like opening a vent or throttling a valve).

- Configurable Electrical Trip Points: The mechanical system of adjustable fingers (contacts) provided the first widely used method for setting precise, customizable high and low electrical trip points on an analog dial. This is the ancestor of the setpoint configuration found in every modern digital process controller and safety interlock.

- Primitive Closed-Loop Control: The magnet/damper mechanism established a foundational model for Closed-Loop Control in industrial safety:

- Sensing: Pressure exceeds limit.

- Actuation: Electromagnet triggers.

- Correction: Damper closes to reduce pressure.The system automatically seeks to return the measured variable (pressure) to the safe range, a defining feature of modern automation.

- Visual Setpoint Indication: By placing the adjustable contacts directly on the gauge face, the safe operating range was made immediately apparent to the operator, a concept used in modern color-coded gauge faces and digital displays that visually mark control limits.