Henry Creamer received U.S. Patent No. 313,854 for a Steam Feed-Water Trap on March 17, 1885. This invention was designed for steam power systems, specifically to automatically return condensed steam (condensate) from heating systems or other steam-using apparatus back to the boiler. This process, known as “trapping,” is crucial for improving the efficiency of steam systems, reducing fuel consumption, and preventing boiler damage.

Detailed Description from the Patent:

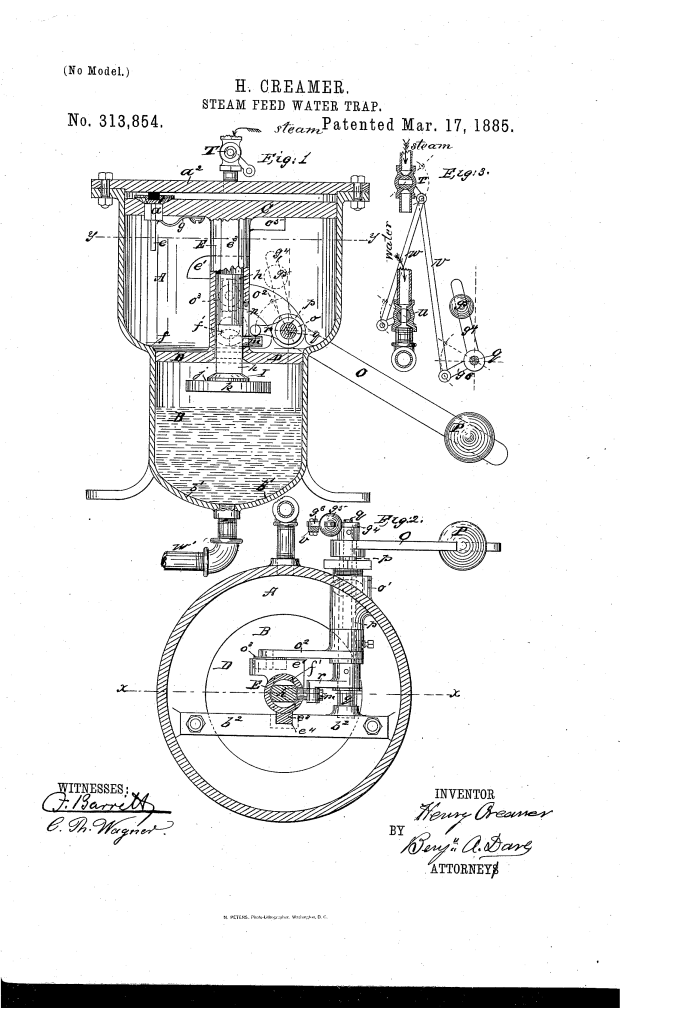

Creamer’s invention focused on a particular type of steam trap, likely a tilting or bucket trap, designed for reliable and automatic operation. The patent details a mechanism for collecting condensate and, once a certain volume is reached, using the weight or buoyancy to trigger a valve that allows the condensate to be returned to the boiler, often against boiler pressure.

Key elements and operational principles would include:

- Receiver or Reservoir (A): A chamber or vessel designed to collect the condensate as it forms and drains from the steam system. This is the primary collection point for the water before it is returned.

- Inlet for Condensate (B): A pipe or opening through which the condensed steam flows into the receiver from the heating coils or other steam-consuming apparatus.

- Outlet for Boiler Return (C): A pipe or opening through which the collected condensate is discharged back to the boiler. This outlet would typically be connected to a check-valve to prevent backflow from the boiler.

- Movable or Tilting Element (D): A core feature of many traps of this era. This could be a tilting tank, a float, or a bucket inside the receiver. The movement of this element is triggered by the accumulation of condensate.

- Valve Mechanism (E): Connected to the movable element, this mechanism controls the flow of steam (or air) to either equalize pressure for discharge or to provide a motive force for the trap’s operation. When the receiver fills with condensate, the movable element shifts, operating the valve.

- Steam/Pressure Connection (F): A line from the boiler or a high-pressure steam source that is used to “blow” or push the collected condensate out of the trap and back into the boiler when the trap’s internal valve opens. This allows condensate to be returned even against boiler pressure.

- Vent/Air-Valve (G): Often, traps would include a small vent or air-valve to release air or non-condensable gases that might accumulate in the system, which can impede efficient operation.

- Automatic Operation: The design emphasizes automaticity. As condensate fills the receiver, its weight or buoyancy causes the tilting element or float to move. This movement then mechanically triggers the valve, allowing steam pressure to push the condensate back to the boiler. Once emptied, the trap resets, ready to collect more condensate.

The advantages of Creamer’s specific design:

- Improved Efficiency: By returning hot condensate to the boiler, it conserves energy that would otherwise be lost if cold feedwater were introduced.

- Automatic and Reliable: Designed to operate without constant manual intervention, ensuring continuous condensate return.

- Prevention of Water Hammer: By efficiently draining condensate, it helps prevent water hammer in steam lines, which can damage pipes and equipment.

- Reduced Water Consumption: Recycling condensate reduces the amount of fresh feedwater needed, saving on water and water treatment costs.

About Henry Creamer

Henry Creamer (dates of birth and death are not widely recorded, but his patent activity is known for the mid to late 19th century) was an African American inventor from New York, New York. While extensive personal biographical information about him is scarce, his patent for the steam feed-water trap is a notable contribution to industrial technology. He is recognized as one of the many African American inventors who made significant, practical improvements to machinery and systems during a period marked by profound racial discrimination. His work highlights the often-overlooked ingenuity of Black individuals in a variety of technical fields.

Personal and Historical Significance of the Invention

Personal Significance for Henry Creamer:

- Demonstration of Engineering Acumen: Obtaining a patent for a sophisticated industrial device like a steam trap showcased Creamer’s deep understanding of mechanical principles, thermodynamics, and the practical needs of steam power systems. This was a remarkable achievement for an African American in the 1880s.

- Formal Recognition of Innovation: The patent served as official documentation of his original contribution, providing a measure of personal validation and recognition for his inventive skill.

- Potential Economic Opportunity: Like other inventors, Creamer likely sought to capitalize on his invention through manufacturing, licensing, or selling the patent rights, offering a potential path to economic advancement.

Historical Significance of the Invention:

- Enhancing Industrial Efficiency: In the 19th century, steam power was the backbone of industry, driving factories, locomotives, and ships. Improvements in steam system efficiency, such as those provided by effective steam traps, directly translated into lower operating costs, less fuel consumption, and more reliable machinery. Creamer’s invention contributed to this vital area of industrial technology.

- Critical Safety and Performance Component: Steam traps are essential for the safe and efficient operation of any steam system. Without them, condensate can accumulate, leading to water hammer, reduced heat transfer, and potential damage to boilers and piping. Creamer’s invention helped ensure these systems operated optimally.

- Contribution to African American Inventive Heritage: Henry Creamer’s steam feed-water trap is a significant example of an African American inventor contributing to complex industrial machinery. His work underscores the diverse range of technical fields in which Black inventors made an impact, often overlooked in mainstream historical narratives. It challenges the misconception that African American innovation was limited to household items, demonstrating sophisticated engineering contributions to the core industries of the era.

- Context of Industrialization: This invention fits squarely within the broader context of the American Industrial Revolution, where continuous improvements in machine design and energy efficiency were paramount. Creamer’s work was a part of this larger wave of innovation.