Stacking Device (William Barry, No. 585,017)

The patent by William Barry of Syracuse, New York, describes an improved Stacking Device (Patent No. 585,017, 1897), filed as a division of his comprehensive mail-canceling machine application. The object is to provide an efficient and durable mechanism to automatically stack and pack mail-matter on edge as it is discharged into a receiving-way.

Inventor Background: William Barry

William Barry was an inventor focused on mechanical solutions for postal and industrial automation. His patents in the 1890s, including the Mail-Canceling Machine and the Stacking Device, were critical to improving the logistical efficiency of handling high-volume mail, emphasizing complex but reliable mechanical sequencing.

Invention and Mechanism

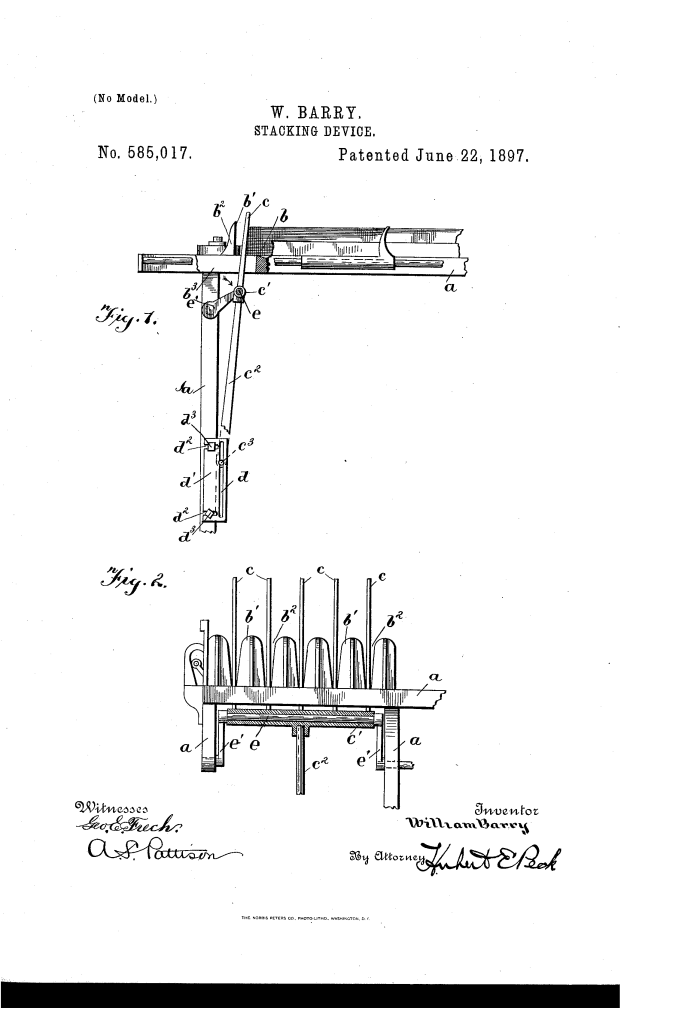

The stacking device is a powered mechanism that moves a letter-engaging pusher in a precise, elliptical path to sequentially pack incoming mail.

1. Receiving Way and Mail Input

- Receiving-Way ($h$): The channel where mail is stacked on edge.

- End Wall ($b$): The wall at the front end of the way is provided with vertical slots ($b^{2}$) and corresponding elongated slots ($b^{3}$) in the floor. Mail is discharged immediately behind this wall.

2. The Stacker Mechanism (Key Innovation: Controlled Elliptical Motion)

- Pusher (Letter-Engaging Portion $c$): A series of upright slats/fingers ($c$) secured to a cross-piece ($c’$) that push the letters.

- Movable Fulcrum: The pusher has a downward-extending shank ($c^{2}$) whose lower end has a lateral pivot/pintle ($c^{3}$). This pintle constitutes the fulcrum of the pusher and is confined to slide within a vertical slot ($d$) in a fixed plate ($d’$).

- Function: This slot confines the fulcrum’s movement, forcing the pusher to swing in a controlled vertical plane.

- Actuating Means: A crank-shaft ($e$) (from the main machine drive) passes through and turns in the tubular cross-piece ($c’$) of the pusher. The cranked ends ($e’$) of the shaft rotate around the pusher’s body.

- Function: The rotation of the crank-shaft ($e$) compels the letter-engaging portion ($c$) to move in an elliptical or approximately elliptical path .

3. Operation Principle

- Working Stroke: The pusher moves up through the floor slots, rearwardly through the end wall slots (engaging the flat face of the newly discharged letter), and pushes the letter against the mass in the way. During this stroke, the pusher moves transversely across the way to pack and align the letter.

- Return Stroke: The pusher moves down below the floor slots and then forward beneath the receiving way to its starting point, ensuring it is entirely out of the way before the next piece of mail is discharged.

- Path Control: The specific path is determined by the fixed geometry of the vertical guide slot ($d$) acting as the movable fulcrum, ensuring the pusher performs the correct compound motion (inward push + downward drop) with reliability.

Concepts Influenced by This Invention

Barry’s stacking mechanism influenced the design of subsequent high-speed paper and currency handling machinery by pioneering the use of complex kinematic linkages for accurate, non-interfering stacking.

- Complex Path Pushers (Kinematic Stacking): The use of a crank-driven linkage with a constrained, movable fulcrum to generate a specific, non-linear (elliptical) motion for the pusher influenced the design of modern currency sorters, paper collators, and high-speed stackers . These systems require the pusher to move quickly into the product path, perform a precise push/align motion, and then rapidly retract out of the path of the next incoming item.

- Controlled Non-Interference: The mechanism ensures that the pusher drops below the working plane on its return stroke and moves out of the way of the incoming mail, establishing a critical engineering principle for continuous, high-speed automation where components must operate in close, sequential proximity without colliding.

- Adjustable Kinematics: The provision for adjusting the position of the fulcrum slot ($d$) allowed the operator to vary the stroke length and horizontal throw of the pusher, influencing the design of modern machinery that requires quick, mechanical calibration to handle different sizes of product.