Stacking Device (William Barry, No. 584,842)

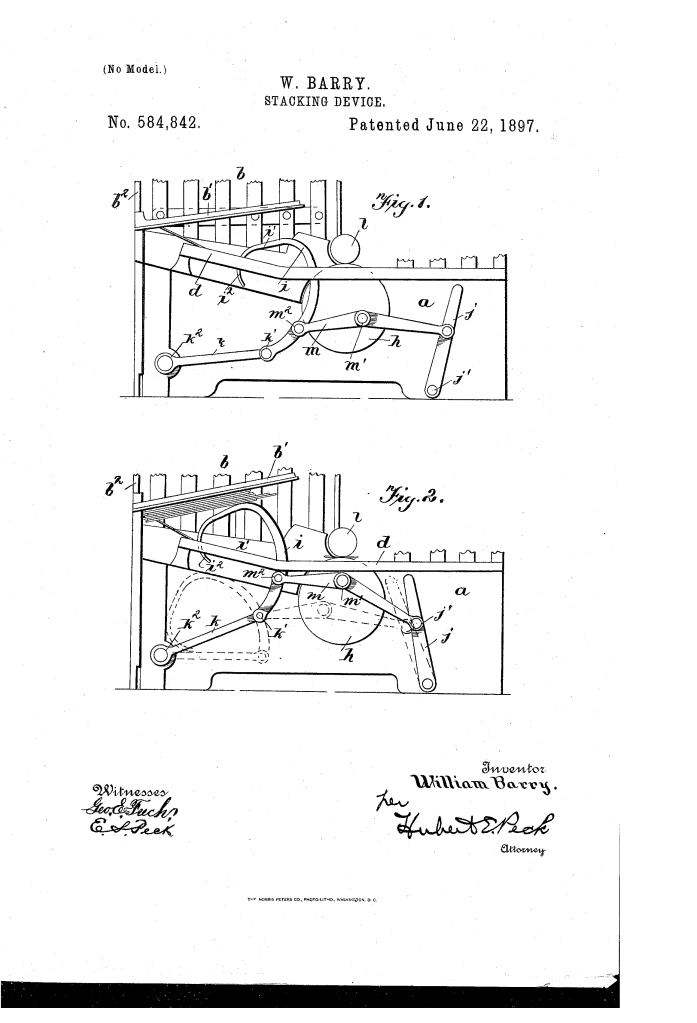

The patent by William Barry of Syracuse, New York, describes a Stacking Device (Patent No. 584,842, 1897). The invention is primarily adapted for use in mail-marking machines (canceling and sorting letters) and aims to provide an efficient and automatic mechanism to stack mail-matter on edge and align the letters against a side guide as they are discharged.

Inventor Background: William Barry

William Barry was an inventor focused on mechanical solutions for office, commercial, and postal automation. His invention addresses a necessary logistical step in the industrial processing of mail: automatically taking individual pieces (letters) and reliably organizing them into a neat, stacked, and aligned batch for the next stage of processing.

Invention and Mechanism

The stacking device is a complex mechanical linkage that converts the rotation of a drive roll into a precise, elliptical motion for the pusher arm.

1. Frame and Mail Delivery

- Floor (a) and Receiving-Way (): The floor or table of the mail-marking machine, where letters are stacked.

- Side Guide (): A longitudinal guide against which the mail-matter is to be aligned.

- Feed Rolls (): Two rolls that grip and discharge letters separately on edge into the receiving-way (

).

2. The Stacker Mechanism (Key Innovation)

- Pusher (): An approximately J or L-shaped pusher (with a rounded inner end

) that operates to push letters into the stack.

- Movable Fulcrum: The pusher’s shank is pivotally joined (

) to a swinging link () that is fulcrumed to the floor. This gives the pusher a movable or shifting fulcrum.

- Actuating Linkage:

- Lever (): A swinging lever pivoted (

) to the floor, arranged to one side of the drive roll (

).

- Pitman (): A rod pivotally joined to the lever (

) and eccentrically joined to the drive roll () via a crank (

).

- Connection: The pitman (

) is also pivotally joined to the pusher’s shank at (

).

- Lever (): A swinging lever pivoted (

3. Elliptical Motion and Alinement

- Path of Movement: The unique linkage (eccentric drive, pitman, swinging lever, and movable fulcrum link) compels the pusher (

) to swing in a precise, approximately elliptical path into and out of the receiving way (

).

- Working Stroke: The pusher enters the way behind the letter just discharged (

) and then moves inwardly toward the rear end of the way, and at the same time transversely toward the side guide (

).

- Function: This two-part motion ensures that each piece of mail is pushed into the mass of stacked letters and is laterally aligned against the guide (

), before the pusher quickly retracts.

- Function: This two-part motion ensures that each piece of mail is pushed into the mass of stacked letters and is laterally aligned against the guide (

- Return Stroke: The pusher swings outwardly, entirely out of the way, just as the next letter enters, ready to re-enter for the next piece.

Historical Significance and the Inventor

William Barry’s 1897 patent is a critical development in the history of postal and sorting automation.

- Postal Automation: The late 19th and early 20th centuries saw massive increases in mail volume. Machines were needed for processes like canceling (mail-marking). The challenge was that mail enters these machines individually but must exit stacked and aligned. Barry’s device provided a reliable, high-speed, mechanical solution to this logistical bottleneck.

- Complex Kinematics: The invention is significant for its complex kinematic design. It uses simple components (levers, links, and a crank) to synthesize a complex, non-circular path (the ellipse) that achieves a very specific, practical goal: pushing in and pushing sideways simultaneously.

- The Inventor (William Barry): Barry was focused on industrial efficiency and automation, contributing a highly specialized mechanical system to the commercial and governmental processing sectors.

Concepts Influenced by This Invention

Barry’s stacking mechanism influenced the design of subsequent high-speed paper handling, sorting, and packaging machinery by pioneering the use of precisely controlled, multi-axis pushers.

- Complex Path Pushers (Kinematic Linkages): The use of an eccentrically driven pitman combined with a constrained lever and a movable fulcrum to generate a specific, non-linear (elliptical) motion is a principle used in modern:

- High-Speed Feeders and Stackers: Machinery for paper, currency, or product handling that requires pushers to move in quickly, act laterally, and retract immediately to clear the path for the next item.

- Packaging and Labeling Machines: Indexing and positioning systems that use multi-bar linkages to perform a precise pick-and-place or push-and-align motion.

- Product Alignment Automation: The specific goal of using a pusher’s inclined and transverse motion to align a product laterally against a guide wall is a fundamental design requirement for modern stacking conveyors and industrial product packaging lines .

- Single-Arm Actuation for Stacking: The solution demonstrated that a single, fast-moving, J-shaped arm could reliably handle the alignment and stacking of discrete items, which is a standard feature in many modern manufacturing and postal automation systems.