Spring Seat for Chairs (Albert B. Blackburn, No. 380,420)

The patent by Albert B. Blackburn of Springfield, Ohio, describes a Spring Seat for Chairs (Patent No. 380,420, 1888). This invention is a modular, high-comfort seating system designed for chairs, sofas, and stools. Blackburn’s primary innovation was the creation of a self-contained spring-and-lever frame that could be manufactured separately and “retrofitted” into various styles of furniture. By supporting the seat with a series of pivoted blocks and coiled springs, he achieved a level of durability and “elasticity of action” that was superior to the standard upholstered furniture of the late 19th century.

Inventor Background: Albert B. Blackburn

Albert B. Blackburn was a prolific African American inventor and mechanical engineer. While many of his patents focused on the heavy industrial safety of the railroad (such as his railway signals), this 1888 patent shows his versatility in consumer product design. During the Victorian era, luxury furniture was often prone to sagging or spring failure. Blackburn applied his expertise in mechanical linkages to the home, creating a seat that was “cheap and simple in construction” but engineered to prevent the common problem of springs cutting through delicate upholstery fabric.

Key Mechanical Components & Functions

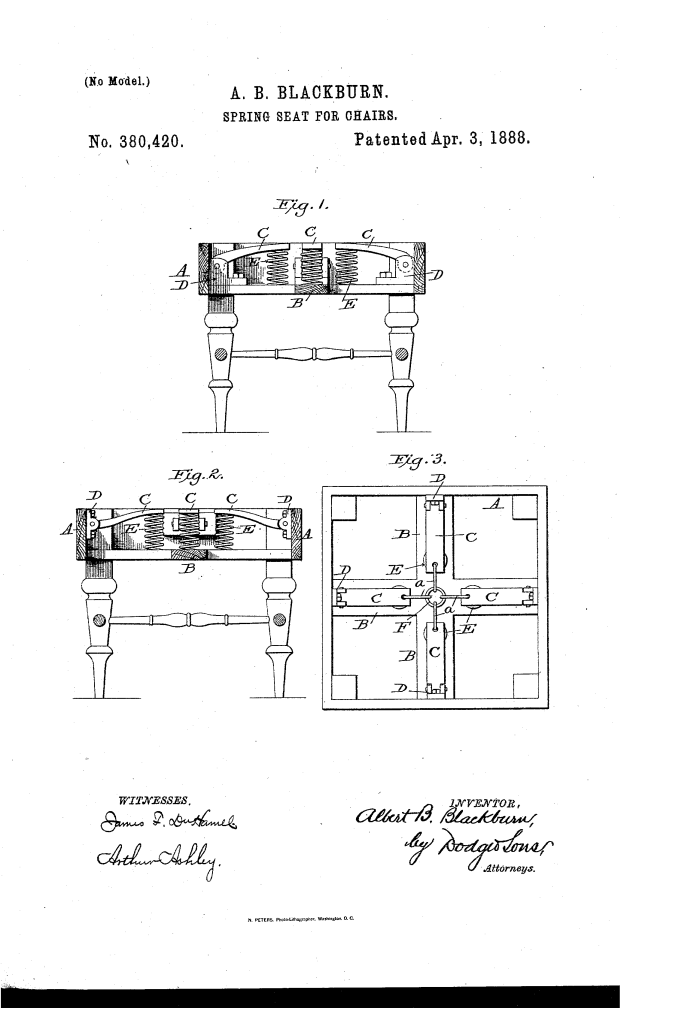

The seat is not a simple pad but a mechanical assembly consisting of a secondary frame, pivoted levers, and equalizing rings.

1. The Secondary Frame (B)

- The Removable Base: Within the main body of the chair (A), Blackburn placed rigid cross-bars (B) that form a separate frame.

- Function: This secondary frame sustains the weight of the occupant. Because it is separate from the chair’s outer body, the entire seating mechanism can be removed for repairs without damaging the furniture’s decorative frame.

2. The Pivoted Blocks (C) and Brackets (D)

- Lever Action: A series of blocks (C)—essentially wooden or metal levers—are pivoted at their outer ends to brackets (D).

- Elevated Tips: The blocks are angled so that their inner ends are higher than their outer ends.

- Function: These blocks act as the “ribs” of the seat. By pivoting them at the outer edge, the seat can “give” and move under the weight of the occupant.

3. The Coiled Springs (E) (Key Innovation)

- Inner Support: Unlike previous designs that placed springs near the pivots, Blackburn placed coiled springs (E) under the free (inner) ends of the blocks.

- Function: This placement maximizes elasticity. Because the springs are at the end of the lever arm, they provide a smoother, more responsive bounce. Furthermore, by keeping the springs tucked deep inside the frame, they are less likely to shift and puncture the upholstery.

4. The Equalizing Ring and Links (F, a)

- Synchronized Movement: At the very center of the seat, the inner tips of the blocks are connected by links or wires (a) to a central ring (F).

- Function: This acts as a “mechanical equalizer.” If an occupant sits slightly off-center, the ring distributes the load across all the blocks and springs simultaneously. This prevents the seat from tilting uncomfortably and ensures the springs wear evenly over time.

Improvements Over Standard Furniture Construction

| Feature | Standard Victorian Upholstery | Blackburn’s Spring Seat |

| Repairability | Required stripping the entire chair. | Secondary frame (B) can be removed as a single unit. |

| Durability | Springs often poked through fabric. | Enclosed blocks (C) protect the upholstery from the springs. |

| Comfort | Prone to “bottoming out” or uneven sagging. | Equalizing ring (F) ensures uniform support. |

| Versatility | Custom-built for each chair. | Can be sold to the trade as a standard part for any chair size. |

Significance to Furniture Engineering

Albert B. Blackburn’s spring seat influenced the development of modular furniture and ergonomic support systems.

- The Modular Insert: Blackburn was one of the first to propose that the functional “engine” of a chair (the springs and frame) should be a separate, mass-produced component. This is a foundational concept in modern manufacturing, where standardized parts are used across different product lines.

- Mechanical Load Balancing: The use of the central ring to equalize spring tension is a sophisticated application of linkage logic, ensuring that the furniture adapts to the occupant’s body position.

- Upholstery Protection: By recognizing that the “outer ends of the blocks… are not exposed,” Blackburn solved a major consumer pain point of the 19th century, increasing the lifespan of expensive textiles.

- Materials Flexibility: His note that the frame could be made of wood or metal showed an early understanding of industrial scaling, allowing the design to be adapted for either high-end hand-crafted furniture or mass-produced factory pieces.