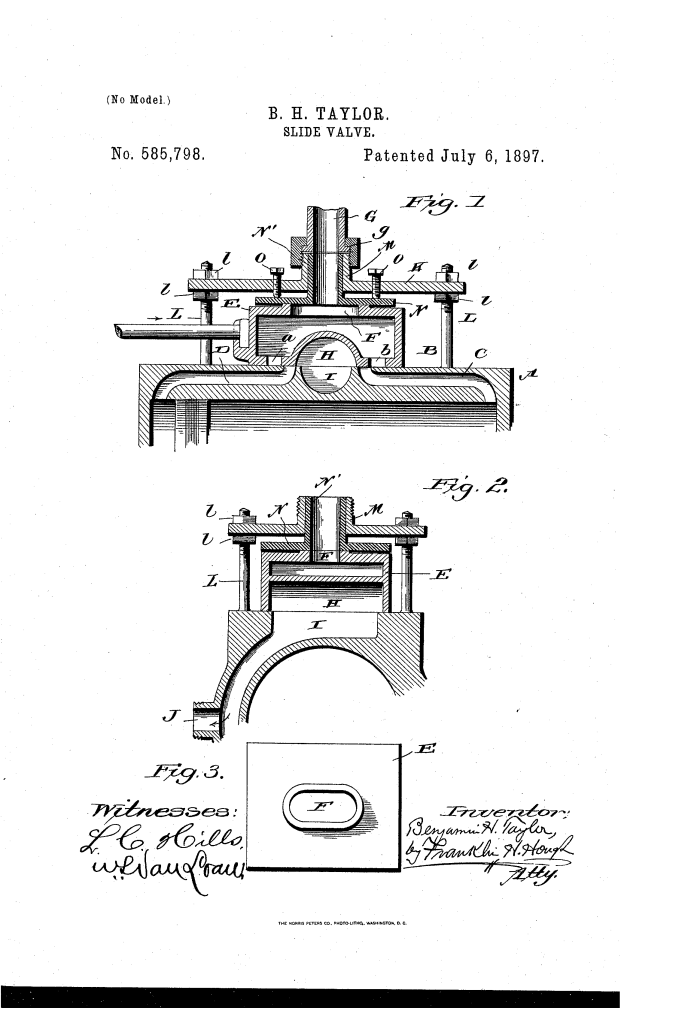

Slide-Valve (Benjamin H. Taylor, No. 585,798)

The patent by Benjamin H. Taylor of Rosedale, Mississippi, describes certain new and useful improvements in a Slide-Valve (Patent No. 585,798, 1897). The invention focuses on providing a balanced slide-valve design that combines the valve and the steam-chest into a single, hollow element, and offers a double means for regulating pressure.

Inventor Background: Benjamin H. Taylor

Benjamin H. Taylor was an inventor working in Mississippi during the late 19th century. He also patented a Rotary Engine (No. 202,888) in 1878, demonstrating a sustained interest in improving steam engine efficiency and design. This later patent shows his focus on refining the traditional slide-valve—a critical component in all reciprocating steam engines—to improve balance and maintenance.

Invention and Mechanism

The improved slide-valve functions as a hollow, pressure-regulated unit that sits on top of the cylinder.

1. The Combined Valve and Steam-Chest (Key Innovation)

- Hollow Valve (E): The valve is essentially a hollow box or chamber that is designed to move over the valve seat (B) on the cylinder (A).

- Function: This hollow interior serves as the steam-chest, eliminating the need for a separate, large external steam chest. Steam is admitted directly into the interior chamber of the valve.

- Exhaust Chamber (H): A semicircular chamber runs through the valve’s longitudinal center, connecting the cylinder’s ports to the main exhaust port (I, J).

- Ports (): Ports on the bottom face of the hollow valve alternately register with the cylinder ports (C, D) to admit steam.

2. Pressure Regulation (Double Adjustment)

A balanced slide-valve is critical; excessive pressure on the valve top increases friction and wear. Taylor provides two ways to adjust the pressure applied to the valve top:

- Lower Adjustable Plate (K): This plate is supported by posts (L) rising from the cylinder and secured by jam-nuts () on the posts.

- Function: By adjusting the jam-nuts, the plate (K) can be moved vertically, allowing the operator to set the general distance from the cylinder head.

- Upper Pressure Plate (N) and Set Screws (O): Plate N rests directly on the upper face of the slide-valve (E). Set-screws (O) pass through the fixed plate (K) and bear against the pressure plate (N).

- Function: Adjusting the set-screws (O) controls the precise degree of downward pressure exerted on the valve (E). This allows for fine-tuning to balance the steam pressure acting underneath the valve, ensuring the valve remains sealed without undue friction.

- Steam Inlet: The steam inlet pipe (G) passes through both plates (K, N) and connects to an elongated opening (F) in the valve top, ensuring continuous steam ingress regardless of the valve’s movement.

Concepts Influenced by This Invention

Taylor’s valve design influenced subsequent engine and fluid control mechanisms by optimizing component integration and pioneering layered, differential pressure adjustment.

- Integrated Component Design (Valve/Chest): The concept of consolidating two distinct, adjacent functions—the pressure chamber (steam chest) and the motion control device (slide valve)—into a single, structurally rigid component (E) influenced the engineering trend toward component integration for reducing size, part count, and complexity in power systems.

- Layered Pressure Regulation: The use of two sequential, adjustable mechanisms (the coarse adjustment via jam-nuts

on plate K, and the fine adjustment via set-screws O on plate N) to control pressure influenced the design of modern multi-stage pressure regulators and precise mechanical calibration systems where both coarse and minute adjustments are necessary for stability.

- Balanced Valve Design: The goal of reducing friction and wear by carefully balancing the steam pressure above the valve against the pressure beneath it is a foundational principle of all modern balanced spool valves, hydraulic control valves, and pneumatic regulators.