Shoe (Selim W. Gunn, No. 641,642)

The patent by Selim W. Gunn of Agawam, Massachusetts, describes improvements in a Shoe (Patent No. 641,642, 1900). The primary object is the production of a shoe that can be adjusted both lengthwise and laterally (width-wise), allowing it to fit feet of different sizes and accommodate changes in the foot.

Inventor Background: Selim W. Gunn

Selim W. Gunn was an inventor focused on utility and consumer goods. His invention addresses the commercial problem of producing shoes that accommodate variable foot sizes and shapes—a key challenge in shoe retail and comfort—by engineering a complex system of internal sliding and lacing adjustments.

Invention and Mechanism (Simplified)

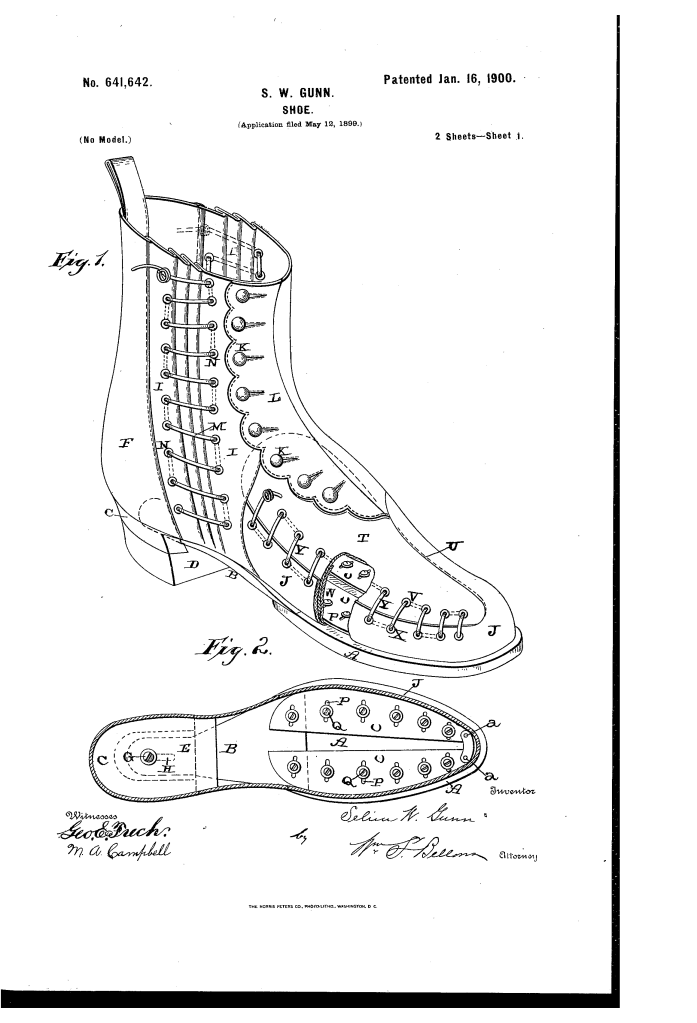

The shoe is built in two primary adjustable segments: the sole/heel (for length) and the upper (for width).

1. Lengthwise Adjustment (Heel and Shank)

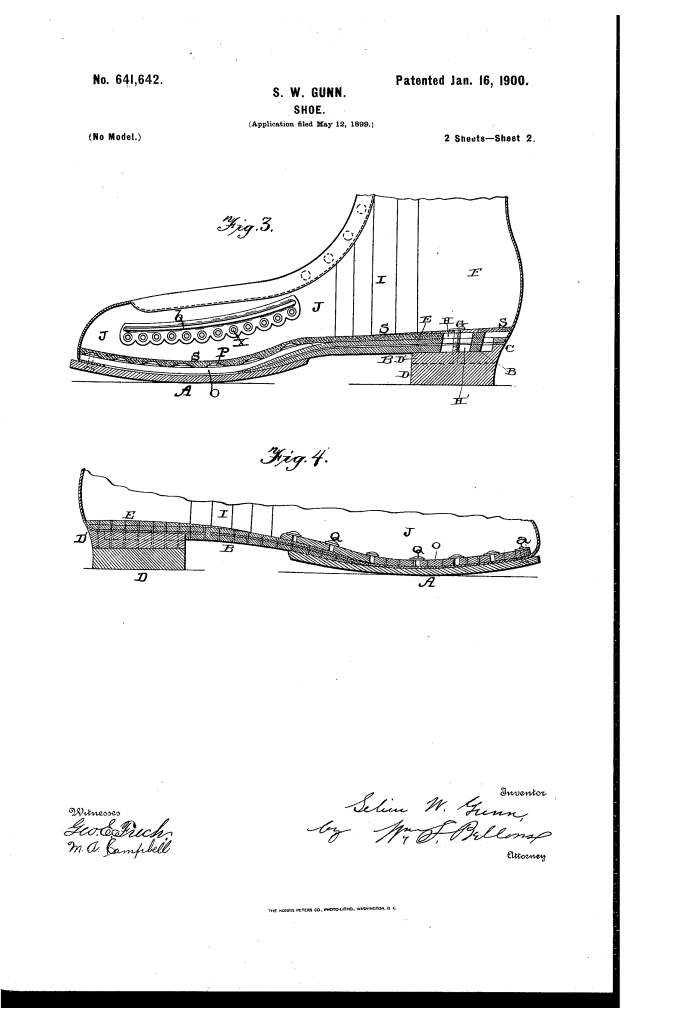

- Two-Part Sole: The sole is formed of a front portion (E, vamp) and a separate circular frame-like part (C) to which the heel (D) is attached.

- Sliding Connection: The front part of the sole is secured to a shank (B) whose rear end overlaps the heel portion (C).

- Clamping Screw (G): A single clamping screw (G) extends through a slot (H’) in the shank (B) and down into the heel (D).

- Function: Loosening the screw (G) allows the rear portion (heel C) to slide forward or backward in relation to the shank (B). This adjusts the shoe’s length to fit different foot sizes or to substitute different heels.

2. Upper Adjustment (Length)

- Inserted Pieces (I): Pieces of fabric or leather are inserted between the vamp (F) and the rear upper (J). These pieces have parallel rows of eyelets (N).

- Function: When the shoe is lengthened, the lacing cord (M) is loosened to let out the inserted pieces (I). When the shoe is shortened, the lace is tightened to contract the fullness (puckers) in the pieces (I), accommodating the length change.

3. Lateral Adjustment (Width) (Key Innovation)

- Adjustable Side Pieces (O): Longitudinal pieces (O) are placed on top of the sole (A) to which the edges of the upper (J) are secured. These pieces have slotted (P) connections to the sole.

- Function: These pieces (O) pivot slightly on their front screws, and the slots (P) allow them to be adjusted laterally (toward or away from each other) to increase or decrease the width of the shoe.

- Upper Width Adjustment: The upper has a separate piece (T) inserted along the top of the foot with lacing (Y) that allows the width to be contracted or loosened to match the lateral sole adjustment.

Concepts Influenced by This Invention

Gunn’s shoe influenced subsequent adjustable and orthopedic footwear designs by pioneering multi-axis modular adjustability in a single item.

- Multi-Dimensional Adjustability: The core concept of engineering a product for simultaneous adjustment in two critical axes (length and width) using separate, coordinated mechanical systems influenced the design of specialized orthopedic braces, adjustable work boots, and custom-fit consumer goods.

- Sliding/Overlapping Adjustment: The use of the slotted shank (H’) and clamping screw (G) to achieve smooth, non-fixed longitudinal adjustment influenced the design of various telescopic and adjustable structures where one component slides within another and is locked by a single fastener (e.g., adjustable shelving or tool handles).

- Flexible Gusset/Lace Sizing: The use of laced gussets (pieces I, T) in the upper to expand and contract the material, accommodating dimensional changes in the sole, influenced the design of modern adjustable/expandable apparel and specialized footwear that uses cinches or drawstrings to achieve custom fit.

- Pivoting Width Mechanism: The design using pivoting side pieces (O) on the sole influenced the mechanical principle behind adjustable-width devices where rotation around a fixed point is used to control the lateral dimension.