Server for Automatic Serving Systems (James Doyle, No. 1,098,788)

The patent by James Doyle of Pittsburgh, Pennsylvania, describes a Server for Automatic Serving Systems (Patent No. 1,098,788, 1914). This visionary invention was designed to automate the restaurant experience, delivering meals from the kitchen directly to dining tables via an overhead track and elevator system. By utilizing a modular, detachable tray system, Doyle sought to eliminate the need for waiters and ensure that diners were served with mechanical precision and hygiene.

Inventor Background: James Doyle

James Doyle was an African American inventor based in Pittsburgh during the early 20th century. His patent, filed in 1912, represents an early and sophisticated attempt at “service automation,” a concept that would later evolve into the “Automats” and modern conveyor-belt sushi restaurants. Living in an industrial powerhouse like Pittsburgh, Doyle applied high-level mechanical engineering—specifically overhead transit and modular coupling—to the hospitality industry. His design focused on scalability, allowing the system to serve any number of guests at a single table without wasting space or effort.

Invention and Mechanism (Simplified)

The system operates like a miniature industrial assembly line installed in a restaurant’s ceiling.

1. The Overhead Transit System (3, 5)

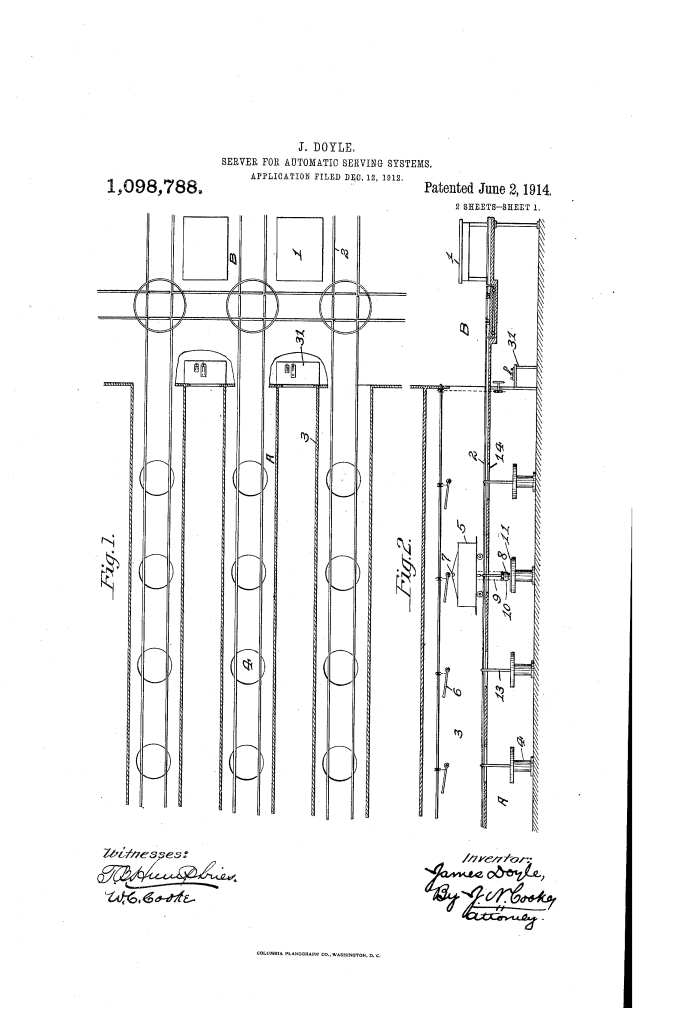

- The Cabinets (3) and Tracks (2): Above the dining room tables, a series of cabinets (3) are installed, connected to the kitchen by tracks (2).

- The Cars (5): Motorized cars (5) travel along these tracks. Controlled by an operator at a central board in the kitchen, a car stops precisely above the target table using a lever and groove alignment system.

2. The Modular Server (8) (Key Innovation)

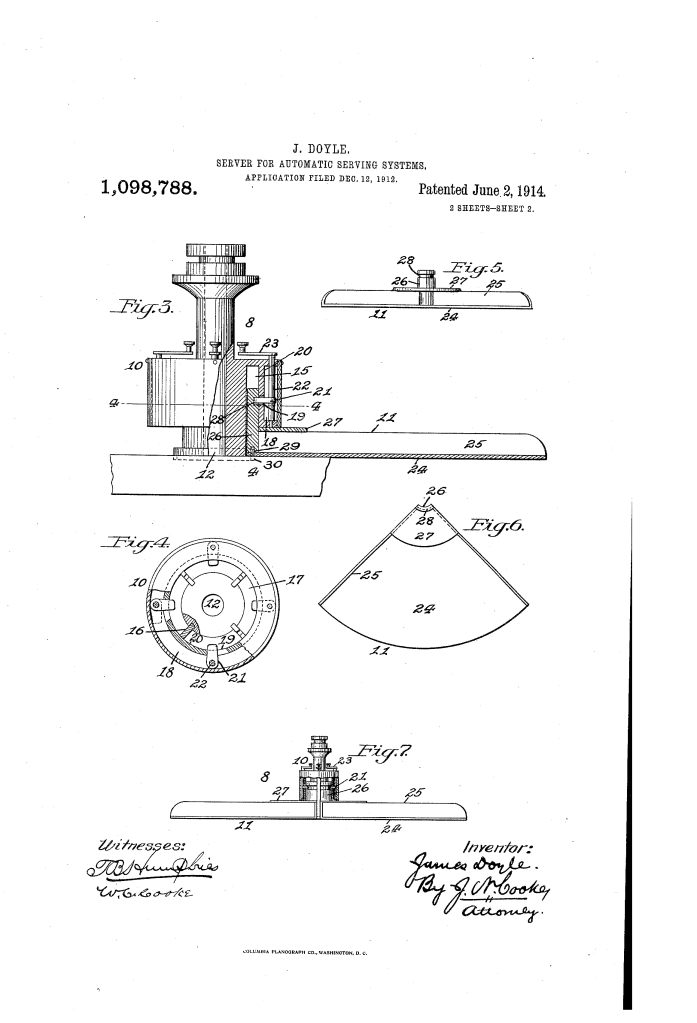

The server itself is not a single large tray, but a two-part modular assembly:

- The Body Portion (10): A central hub connected to the car by chains (9). It features a vertical hole (12) that fits over a guide rod (13) rising from the center of the dining table to ensure it lands perfectly every time.

- Individual Tray Sections (11): These are pie-shaped wedges that hold the food.

- Selective Serving: If only two people are at a table for four, the kitchen attendant only attaches two tray sections to the body. This prevents unutilized trays from cluttering the table.

3. The Latching Mechanism (21, 23, 28)

To keep the food trays attached during their flight across the restaurant, Doyle engineered a secure locking system:

- The Latch (21) and Groove (28): Each tray section has an attaching portion ($26$) with a groove (28).

- The Lever (23): Once the server is lowered to the table, the diner or an automated mechanism turns a lever (23). This rotates a shaft (22) to disengage a latch (21) from the tray’s groove.

- Function: This releases the tray sections onto the table, allowing the body portion (10) to be raised back into the ceiling cabinet, leaving the diners with their meals.

4. Alignment and Collection (29, 30)

- Table Flange (30): The table surface has raised flanges (30).

- Base Groove (29): The bottom of each tray section has a corresponding groove (29).

- Function: This ensures the trays stay in exact alignment on the table. When it is time to clear the table, the central body is lowered again, and the flanges ensure the trays are perfectly positioned to be re-latched and lifted back to the kitchen.

Concepts Influenced by This Invention

James Doyle’s automatic server influenced the fields of hospitality automation and modular logistics.

- The Modern “Automat”: Doyle’s focus on eliminating the “middleman” (waiters) for efficiency and speed was a precursor to the 20th-century Automat and modern digital-ordering kiosks.

- Overhead Conveyor Systems: The use of ceiling-mounted tracks to save floor space is a principle now standard in high-efficiency industrial warehouses and modern garment handling systems.

- Modular Payload Delivery: The logic of a “central carrier” (the body) delivering “variable payloads” (the tray sections) is a fundamental concept in modern robotics, where a single robot arm can swap different tools or parts depending on the task.

- Precision Guidance: The use of a fixed guide rod ($13$) to stabilize a suspended load during descent is a classic engineering solution for “docking” procedures, seen in everything from heavy maritime crane operations to space station docking modules.