Separating-Screen (Thomas Henry Edmonds, No. 586,724)

The patent by Thomas Henry Edmonds of Washington, D.C., describes a new and useful Separating-Screen (Patent No. 586,724, 1897) designed to be inserted in water-supply pipes. The invention’s object is to provide a durable and easily serviceable screen capable of withstanding the high pressure of water, preventing lint, scale, shell, or any foreign substance from passing through the pipes. It is specifically intended for use with automatic valve-regulators.

Inventor Background: Thomas Henry Edmonds

Thomas Henry Edmonds was an inventor focused on utility and maintenance solutions for infrastructure, particularly in fluid handling. His screen design directly addresses a failure point—the inability of prior screens to withstand high water pressure without rupturing or dislodging—which was critical for maintaining the reliability of automated systems like valve regulators.

Invention and Mechanism

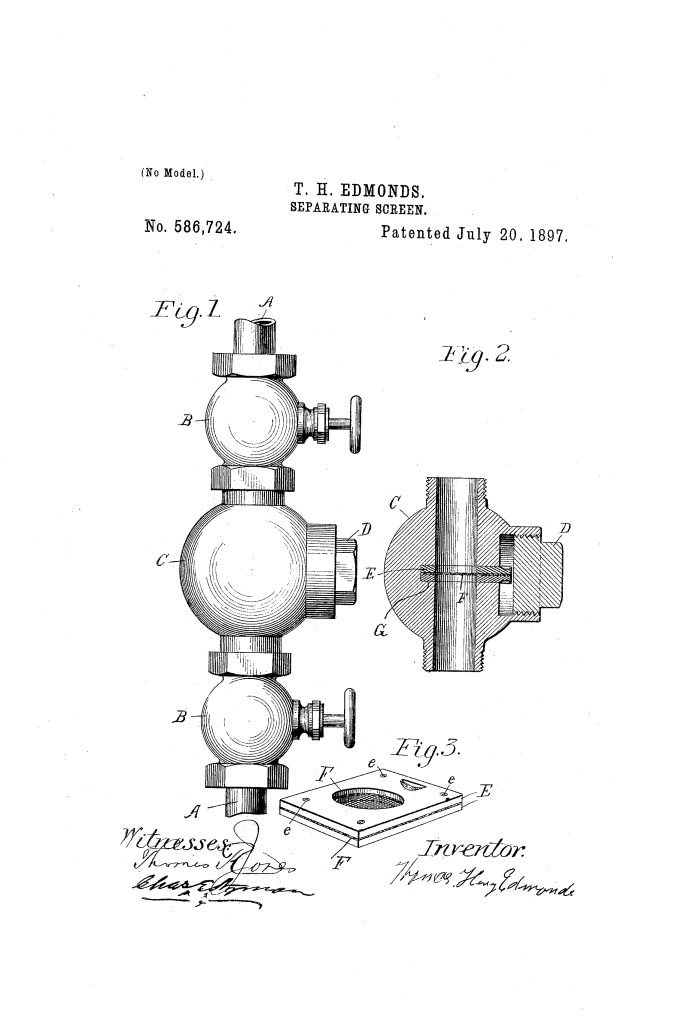

The invention is a specialized, rigid, easily removable screen unit designed to resist high internal fluid pressure.

1. Screen Chamber and Housing

- Water-Supply Pipe (A): The pipe section where the screen is installed. It has inflow and outflow valves (B, B).

- Screen-Chamber (C): A section of the pipe with a suitable slot or recess (G) cut transversely into it.

- Plug or Bonnet (D): A threaded cap that screws firmly down into the chamber.

- Function: The plug (D) not only closes the opening but also serves to hold the screen rigidly in place in the recess (G) and prevent fluid from bypassing it.

2. The High-Pressure Screen (Key Innovation)

- Framing Plates (E, E): The screen is composed of two apertured framing-plates.

- Wire Fabric: The filtering wire fabric is placed between the two framing plates (E, E).

- Detachable Union: The plates are detachably secured together by screws () or other suitable means.

- Function: This design allows the plates to firmly clamp the wire fabric between them, forming an exceedingly solid structure. This clamping force prevents the wire fabric from being pulled out under high water pressure or when a large amount of sediment has collected, solving the primary failure mode of prior screens.

3. Maintenance

- Ease of Service: The screen can be instantly removed by closing the inlet valve, unscrewing the plug (D), and pulling out the framed screen. Because the plates are detachably united, the worn wire fabric can be replaced easily without discarding the entire frame.

Concepts Influenced by This Invention

Edmonds’s design influenced subsequent filtration and piping systems by pioneering a rigid, serviceable, and pressure-resistant filter unit.

- High-Pressure Filter Housings: The design principle of using a transverse slot or recess (G) sealed by a screw-on bonnet/plug (D) for housing a filter cartridge is standard in modern industrial strainers, pipeline filters, and chemical process line filters . This allows the line to be opened and the filter removed without cutting the pipe.

- Cartridge-Style Filter Element: The concept of creating a pre-assembled, rigid filter element (the wire fabric clamped between plates E) that is dropped into a housing influenced the design of all modern replaceable filter cartridges and elements . This rigidity ensures the filter media maintains its integrity against high flow and differential pressure.

- Pressure Resistance via Clamping: The method of achieving pressure resistance by clamping the filter media (wire fabric) between two solid plates is a key technique in modern industrial and hydraulic filtration, where the filter media itself is not solely responsible for containing the pressure.