Billiard-Cue Rack (Richard B. Spikes, No. 963,834)

The patent by Richard B. Spikes of Albuquerque, New Mexico, describes a Billiard-Cue Rack (Patent No. 963,834, 1910). The invention provides a way for pool hall owners to simultaneously lock all cues in a rack, preventing unauthorized “practice” that causes excessive wear and tear on expensive billiard balls, cues, and table cloth. The design allows the proprietor to unlock all cues with a single key when a paying customer is ready to play.

Inventor Background: Richard B. Spikes

Richard B. Spikes (1878–1963) was a prolific African-American inventor whose work spanned many industries, including automotive, rail, and consumer goods. Residing in the Territory of New Mexico at the time of this patent, Spikes was known for his ability to improve existing mechanical systems. His most famous inventions include an improved gear shift mechanism, the automatic brake safety system, and a beer keg tap. This cue rack invention showcases his early mechanical ingenuity in solving practical business problems through integrated locking systems.

Invention and Mechanism (Simplified)

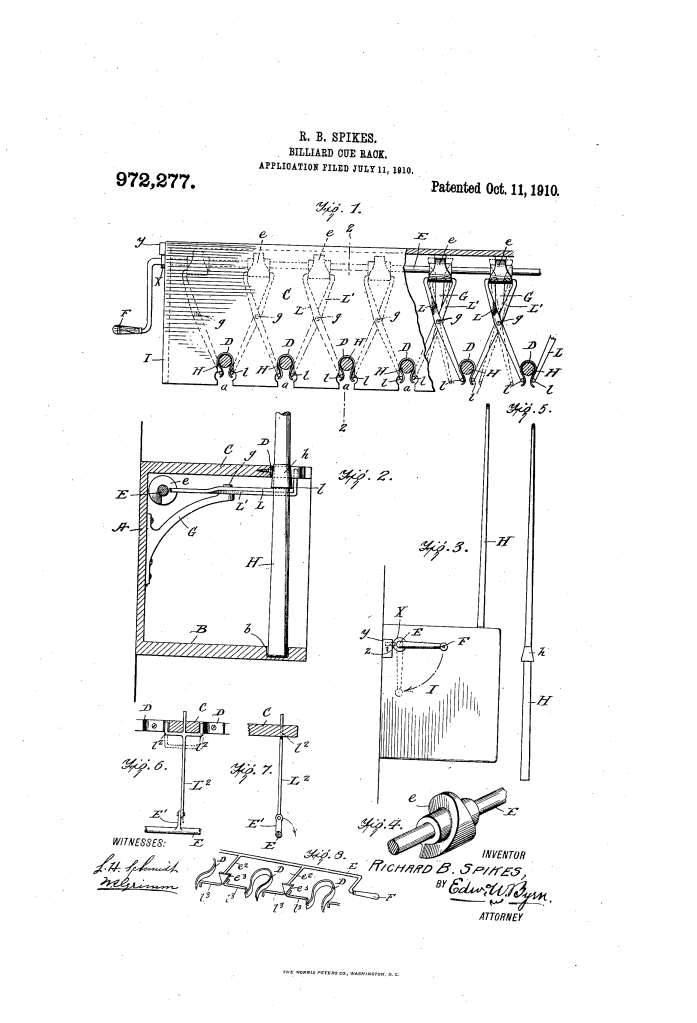

The rack secures cues by using spring clasps that are physically blocked from opening by a series of cam-operated levers.

1. Frame and Spring Clasps

- Frame (A, B, C): The rack consists of a back (A), a base (B) with bored seats ($b$) for the cue butts, and a top member (C) with slots ($a$) for the cue bodies.

- Spring Clasps (D): Each top slot contains a circular spring clasp. These clasps are sized to fit a cue snugly; they can expand to let a cue out, but only if the spring ends are allowed to move.

2. The Locking Mechanism (Key Innovation)

- Crossed Levers (L): A pair of crossed “scissor” levers is fulcrumed behind each cue slot. The front ends of these levers have lugs ($l$) that rest behind the ends of the spring clasps.

- Rotary Cam Shaft (E): A horizontal shaft runs the length of the rack. On this shaft are tapering, wedge-shaped cams ($e$).

- Locked Position: When the shaft is turned so the thick part of the cam is between the rear ends of the levers, the front lugs ($l$) are forced tightly against the spring clasps. This prevents the springs from expanding, making it impossible to pull the cue out laterally.

- Unlocked Position: When the shaft is turned to the thin part of the cam, the levers can move freely, allowing the spring clasps to expand so the cues can be removed.1

3. Security and Anti-Theft Features

- Master Lock (2$y$): The shaft (E) is controlled by a crank handle (F).3 A notched collar ($X$) on the shaft engages a lock bolt ($2$). The proprietor uses a key to retract this bolt, allowing the shaft to turn and unlock all cues at once.

- Conical Collar ($h$): Each cue is equipped with a small tapered collar (4$h$) where the clasp grabs it.5

- Function: This prevents a person from simply lifting the cue vertically out of its base socket and sliding it down through the clasp. The taper creates a physical stop that prevents the cue from moving upward while the clasp is locked.

Concepts Influenced by This Invention

Spikes’s cue rack influenced the development of centralized mechanical security and multi-point locking systems.

- Centralized Multi-Point Locking: The core concept of using a single rotating shaft with multiple cams to actuate and lock numerous independent stations simultaneously is a foundational principle in modern security. This is seen today in multi-point locking doors and centralized industrial tool storage.

- Interlocking Mechanical Logic: The combination of the spring clasp and the cam-wedge creates a “mechanical interlock”—a system where a secondary part (the lever) provides the structural integrity for the primary part (the spring).6 This is a common theme in fail-safe mechanical engineering.

- Prevention of Multi-Axis Movement: By using the conical collar ($h$) to prevent vertical movement and the locked clasps to prevent lateral movement, Spikes demonstrated an early mastery of “restricting degrees of freedom,” a critical concept in mechanical design and robotics.

- Business Process Automation: The invention shifted the burden of enforcement from the proprietor (asking friends to stop practicing) to the machine itself, an early example of using technology to manage social and commercial interactions.