Sealing Attachment for Bottles (Robert Hearns, No. 598,929)

The patent by Robert Hearns of St. Paul, Minnesota, describes a Sealing Attachment for Bottles (Patent No. 598,929, 1898). The object is to provide an improved sealing attachment that prevents refilling of the bottle after it has been emptied of its original contents, serving as a safeguard against fraudulent substitution or dilution of high-value liquids (like spirits).

Inventor Background: Robert Hearns

Robert Hearns was an inventor focused on commercial security and anti-fraud solutions. His invention targeted a major problem in the late 19th-century retail and hospitality industries: the illegal practice of refilling liquor or medicine bottles with inferior or counterfeit liquids. The co-assignment to Sam Black suggests a commercial intent to mass-produce and market the security device.

Invention and Mechanism

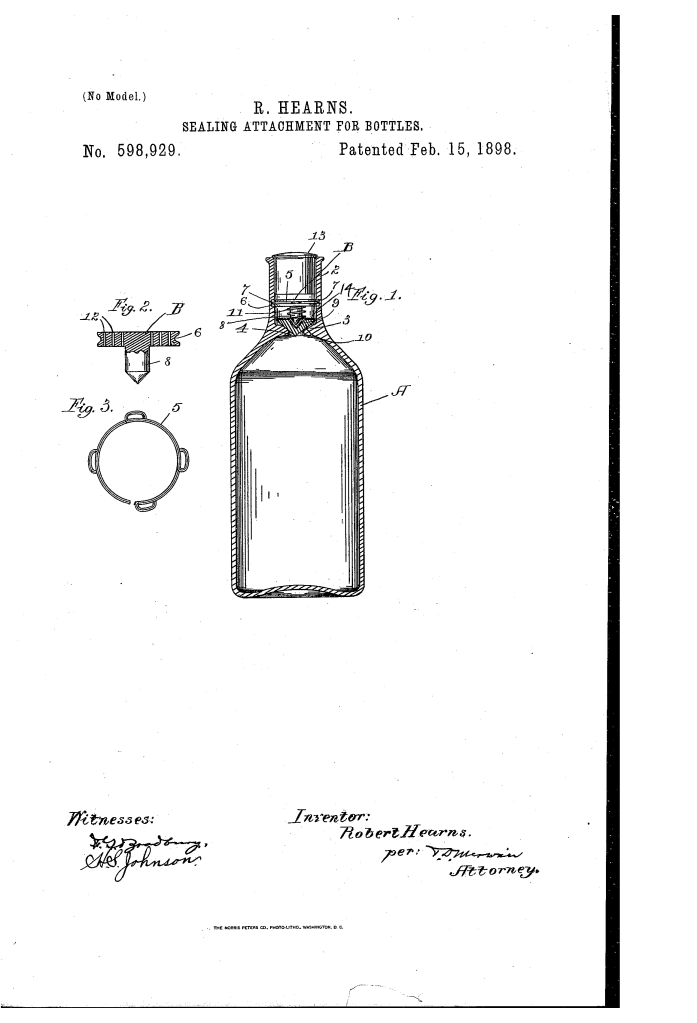

The device is a non-removable, spring-loaded valve assembly inserted into the bottle neck, which is designed to open outward only under the weight of the original liquid.

1. Bottle and Valve Seat

- Bottle Neck (2): The neck has an inwardly-projecting annular flange (3) at the bottom, creating a constricted central throat (4) that serves as the valve seat.

- Valve (10): A valve (often non-metal with metallic sheathing 14 to prevent tampering) is sized to seat snugly in the throat (4).

2. The One-Way Flow Mechanism (Key Innovation)

- Coil Spring (11): A light coil spring surrounds a central stem (8) and abuts against the valve (10) and the guard-disk (B).

- Function (Refilling Block): The spring (11) is of sufficient strength to hold the valve (10) firmly to its seat when the bottle is empty or upright, preventing liquid from being forced back into the bottle.

- Outflow (Emptying): The spring (11) is weak enough to be compressed by the weight of the liquid when the bottle is held in the inverted position. This allows the liquid to pass around the valve and exit through ports (12) in the guard-disk (B).

3. Permanent Sealing Guard

- Guard-Disk (B): A disk arranged above the valve (10) with multiple vertical openings (12) for liquid outflow.

- Securing Spring (5): The guard-disk (B) is held permanently in place by a spring-ring (5) that fits into corresponding circumferential grooves (6, 7) in the disk and the bottle neck.

- Function: Once the guard-disk (B) is inserted, it locks permanently into the neck, making the entire anti-refill mechanism non-removable without destroying the bottle.

Concepts Influenced by This Invention

Hearns’s bottle seal influenced subsequent designs in packaging security by pioneering weight-actuated, single-direction valves.

- Anti-Refill Valves (One-Way Check Valves): The core concept of a spring-biased valve that opens only under the force of the liquid’s weight (when inverted) but seals against external pressure (when upright or pressurized) is the functional ancestor of many modern anti-refill mechanisms used in high-value spirits bottles, where the valve ensures single-direction flow.

- Permanent Sealing/Tamper Evidence: The use of a spring-ring locking mechanism (5) to permanently fix a component within the neck influenced the design of various tamper-evident seals, permanent bottle caps, and closures that require physical destruction to be removed, guaranteeing product integrity.

- Internal Check Valves: The valve mechanism functions as an internal, gravity-independent check valve, preventing reverse flow under normal pressure—a principle widely used in fluid engineering.