Reversing-Valve (Brinay Smartt, No. 799,498)

The patent by Brinay Smartt of Nashville, Tennessee, describes certain new and useful Improvements in Reversing-Valves (Patent No. 799,498, 1905), designed particularly for locomotive-engines. The main object is to simplify the construction of the reversing mechanism by obviating the employment of the usual link-motion (a complex system of rods and levers) and replacing it with a simple, small lever and intermediate connections.

Inventor Background: Brinay Smartt

Brinay Smartt was an African-American inventor and entrepreneur focusing on rail technology and industrial efficiency. His invention directly tackled the complexity and operational difficulty of the standard link-motion valve gear, which was heavy, cumbersome, and required great effort to operate. His goal was to create a simplified, reliable system that could be easily operated by the engineer.

Invention and Mechanism (Simplified)

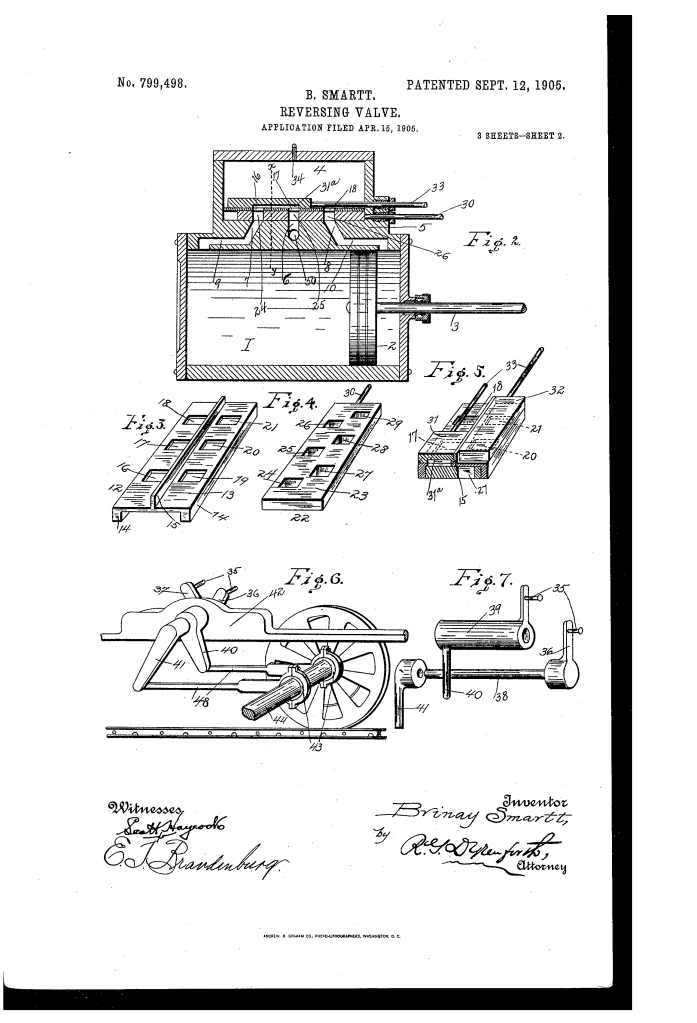

The invention replaces the external link motion with a simplified, short-throw system using stacked internal plates and a unique dual rocker-arm assembly.

1. The Internal Valve Plates (Key Innovation)

- Removable Valve Seat (12): A plate with downturned flanges that rests unsecured within the steam chest (4). This is designed to be easily removable for maintenance or substitution.

- Reversing-Valve (22): A second, oblong plate that slides beneath the valve seat (12) and is guided by its flanges. This plate has staggered openings (24-29).

- Function: Moving this plate (22) controls which set of ports in the valve seat (12) are open. When one set is open for forward motion, the other set is blocked. Moving the reversing-valve (22) reverses this alignment, thereby reversing the engine’s direction.

- Steam-Valves (31, 32): Two plates that slide on top of the valve seat (12). They are driven by the engine’s eccentrics and control the final admission of steam to the cylinder ports.

2. Reversing and Throttle Control

- Short-Throw Lever: The entire reversing mechanism is operated by a small, convenient lever in the cab (the “reverse-lever 39”), about the size of a throttle lever.

- Mid-Position Cutoff: The openings in the reversing-valve (22) are arranged so that when the reverse-lever (39) is moved to its middle notch, all steam ports are closed or blanked.

- Function: This allows the reversing-valve (22) to double as an emergency throttle, stopping the engine if the main throttle fails.

3. Rocker-Arm System

- Dual Rocker-Arms (36, 37): A pair of rocker arms is used to operate the two steam valves (31, 32).

- Space Saving: The two arms work together by having their shanks telescope into one another (38, 39).

- Function: This arrangement allows two rocker-arms to occupy the space usually needed for one, minimizing space and easing maintenance.

Concepts Influenced by This Invention

Smartt’s reversing valve influenced subsequent industrial and motive power design by pioneering compact, multi-functional valve systems that replace complex external kinematics.

- Valve Consolidation (Link-Motion Elimination): The core influence is the successful mechanical design that replaces the external, cumbersome link motion (Walschaerts or Stephenson gear) with a simple, high-leverage internal valve plate (22). This simplified the maintenance and operation of the entire locomotive.

- Integrated Safety/Throttle Function: The concept of designing a control element (the reverse valve) to serve a critical safety function (emergency steam cutoff) at its neutral or mid-position influenced the design of various industrial control valves where a single lever provides directional control and safe shutdown.

- Compact, Telescoping Mechanical Components: The use of telescoping shanks in the rocker-arms to minimize the space required for the mechanism influenced the engineering of compact valve actuators and linkages in machinery where space conservation is critical.

- Adjustable Port Staggering: The staggered alignment of the openings in the valve plates influenced the design of fluid control valves that use rotation or linear shifting to precisely time or sequence the opening of multiple channels.

To see the detailed patent go to patents.google.com