Refining Cocoanut-Oil (Alexander P. Ashbourne, No. 230,518)

The patent by Alexander P. Ashbourne of Boston, Massachusetts, describes a novel and improved Process for the preparation of cocoanut-oil for medicinal and general toilet purposes (Patent No. 230,518, 1880). The objective is to refine the oil so that it will “keep sweet and fresh for many years,” preventing rancidity and leaving the final product pure and white.

Invention and Mechanism

The invention details a multi-stage process involving initial oil extraction, purification, and final chemical curing/refinement.

- Oil Extraction:

- Preparation: Grate the coconut meats fine.

- Steaming: Subject the grated meat to steam heat for four hours.

- Boiling/Extraction: Add four gallons of boiling water to every 100 pounds of steamed meat and boil for one hour, stirring frequently.

- Pressing: Subject the mass to a powerful press to remove all the oil, leaving it as a white liquid.

- Purification (Removing Coarse Refuse):

- The extracted oil is brought to a gentle boil until it “gathers a head.”

- The oil is separated from the water, skimmed, and boiled again in porcelain-lined kettles for three hours. This allows the coarse refuse matter to settle, leaving a clear oil on top.

- Final Refinement and Curing (The Claimed Invention):

- Curing Agents: To each gallon of pure oil, the following are added: three tablespoonfuls of pulverized white sugar, the whites and shells of three eggs, and one-half ounce of alum.

- Boiling and Condensation: The mixture is placed over a slow fire for one hour and a half and gently boiled. A condenser is placed over the kettle to catch the steam and evaporation.

- Function: The steam carries off properties that would cause the oil to become rancid. The sugar, alum, and egg ingredients stabilize and purify the product, leaving the oil “pure and white.”

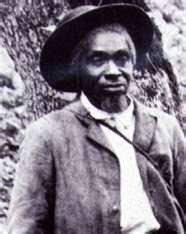

Historical Significance and the Author

- The Inventor (Alexander P. Ashbourne): This is the third known U.S. patent granted to Alexander P. Ashbourne, an African-American inventor. His work in the 1870s and 1880s focused intensely on food and commodity processing, with patents for a biscuit cutter, coconut meat treatment, and now coconut oil refining. His focus on creating a stable, high-quality product reflects an advanced understanding of commercial food chemistry and preservation.

- Commodity Stability: The invention directly addressed the major commercial challenge of coconut oil rancidity. The ability to produce oil that would “keep sweet and fresh for many years” was critical for opening up distant markets (like those for medicinal and toilet uses) and ensuring product reliability.

- Chemical Stabilization: The claimed process—boiling the oil with sugar, eggs (albumen/protein), and alum—demonstrates an early, practical method of chemical stabilization. The albumen acts as a fining agent and emulsifier, while alum and sugar are used as stabilizers and preservatives, refining the product beyond simple physical separation.

Core Concepts Utilized Today

The process employs fundamental techniques still critical in modern cosmetic, food science, and commodity processing, particularly for high-fat products.

- Refining via Stabilization and Fining: The process of boiling with albumen (egg white) and alum is a classic example of fining (a process that uses a substance to clarify liquid by binding impurities) and stabilization. Modern oil and beverage industries use sophisticated fining agents and stabilizers (like specialized clays, gums, or proteins) to bind micro-impurities and remove moisture, achieving the same goal of clarity and long-term stability that Ashbourne sought.

- Steam Distillation/Condensation for Purity: The use of a condenser to capture steam/evaporation during boiling is a simple form of steam distillation. This process is now standard in the cosmetic and essential oil industries to extract or purify volatile compounds and remove unwanted “rancidity-causing properties” (volatile organic acids) from the oil.

- Multi-Stage Thermal Purification: The initial purification stages—boiling to separate water, settling, and skimming—are still core unit operations in all modern edible oil refineries (for palm, soy, and coconut oils) to physically remove moisture and “mother substance” (sludge/impurities) before chemical refinement begins.