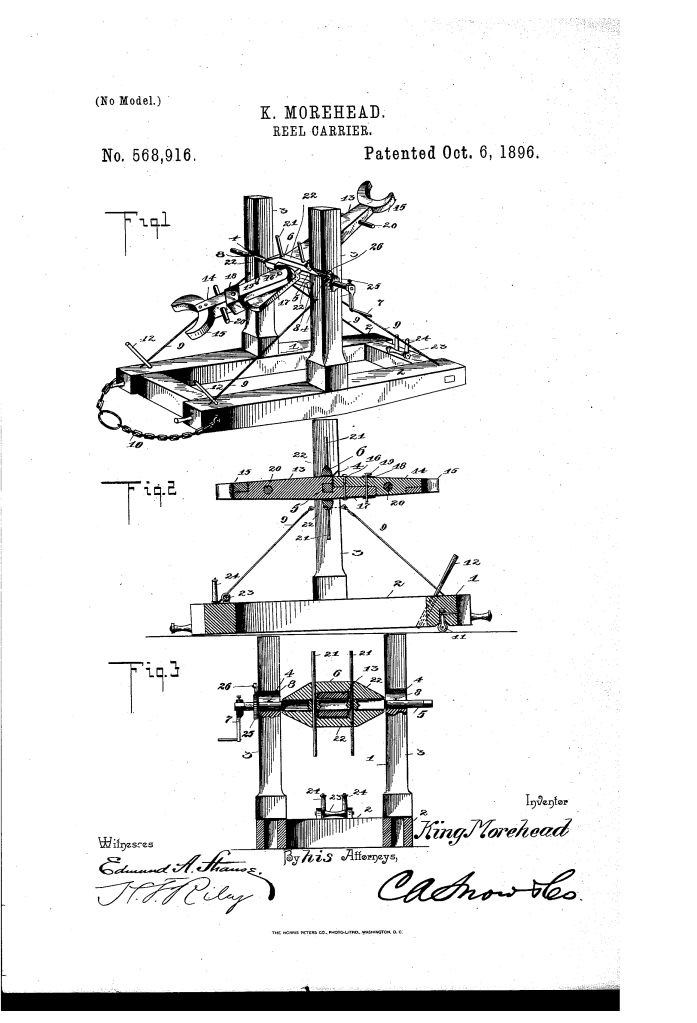

Reel-Carrier (King Morehead, No. 568,916)

The patent by King Morehead of Salisbury, Missouri, describes an improved Reel-Carrier. The invention’s objects are to provide a simple, inexpensive, and efficient carrier for gathering, reeling, unreeling, and stretching fence-wire. A further key object is to enable wire to be removed from the spool without uncoiling it for easy storage.

Invention and Mechanism

The reel-carrier is a portable, anchored frame supporting a specialized, collapsible spool.

1. Supporting Frame and Portability

- Frame (1): Comprises a rectangular base (2) with central vertical standards (3) that have bearing-slots (4) for the reel shaft (5).

- Portability/Anchoring:

- A caster-wheel (11) supports the front of the base, facilitating movement.

- A chain (10) is attached for dragging the frame.

- The base has perforations for stakes or pins (12), allowing the frame to be anchored into the ground at any desired point for wire stretching.

- Ratchet Lock: A ratchet-wheel (25) on the shaft (5) and a pawl (26) on the standard (3) hold the spool against backward movement, enabling wire stretching.

2. The Collapsible Spool (Key Innovation)

The spool (6) is designed to release its wire load without uncoiling.

- Two-Part Arm: The spool comprises a rigid arm (13) and a pivoted arm (14).

- Hinge: The pivoted arm (14) is secured by a pivot (16) to an extension (17) of the rigid arm (13).

- Locking Sleeve (18): A sliding band or sleeve (18) embraces both the extension (17) and the pivoted arm (14). A removable pin (19) locks the sleeve in place.

- Function (Load Release):

- The pin (19) is removed.

- The sleeve (18) is slid outward (aided by the tapering arms).

- The pivoted arm (14) is swung laterally to one side.

- The wire, which has been wound into a coil, can then be slid off the spool whole, without needing to be unreeled. This facilitates easy storage of the gathered wire.

- Wire Heads (15): The ends of the arms have heads presenting outer concave faces to prevent the wire from slipping off the spool accidentally during reeling.

- Pins (21): Centrally arranged pins (21) pass through the spool and the shaft (5) to secure the spool to the shaft.

3. Wire Guide

- Guide Rolls: A horizontal pulley (23) and a pair of vertical rolls (24) are mounted at the rear of the frame to guide the wire onto the spool, ensuring smooth operation during gathering or unreeling.

Historical Significance and the Inventor

King Morehead’s 1896 patent is a practical utility innovation for the rapidly expanding ranching and farming operations across the American West.

- Fencing the Frontier: The late 19th century was the era of extensive land division and the widespread adoption of barbed wire fencing in the United States. Fence maintenance, construction, and removal (especially barbed wire) were constant, labor-intensive necessities.

- Efficiency and Safety: Wire, especially barbed wire, is dangerous and difficult to handle in large, coiled bundles. Morehead’s invention significantly improved the efficiency and safety of wire management by providing dedicated tools for anchoring, stretching, and, most importantly, the quick, mechanical removal of a tightly wound coil. The collapsible spool solved the logistic problem of storage, allowing the wire to be easily bundled after gathering.

- The Inventor (King Morehead): Morehead, residing in Salisbury, Missouri, was based in a region integral to the nation’s agricultural and livestock economy, making the improvement of fencing tools a direct response to regional economic needs.

Core Concepts Utilized Today

Morehead’s reel-carrier utilizes several concepts essential to modern material handling, particularly for coils and cables.

- Quick-Release Collapsible Spools: The central innovation—a spool that hinges open or collapses to release a coiled load without uncoiling the material—is the core principle of modern wire, cable, and shrink-wrap dispensing spools used in construction, telecom, and packaging industries. This allows the finished coil to be quickly packaged or stored.

- Anchored Winding Systems: The ability of the support frame to be anchored with stakes (12) and use a ratchet lock (25, 26) is the basis for portable cable tensioners and winches used in construction, rigging, and utility work, where the machine must be temporarily immobilized to apply high tension to a cable or rope.

- Modular Wire Guides: The use of horizontal and vertical rolls (23, 24) to guide the wire precisely onto the spool is standard practice in all modern reeling, winding, and cable-laying machines to ensure uniform layering and prevent damage to the material.