Reaper (George W. Murray, No. 520,892)

The patent by George W. Murray of Rembert, South Carolina, describes an improved Reaper designed to cut small grain, gather it into bundles, and automatically dump the bundles at proper intervals. The key objectives were simplicity, affordability, and the ability to adjust the cutting height for different harvest conditions.

Invention and Mechanism

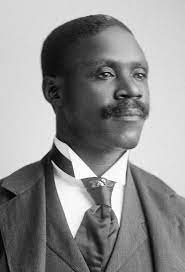

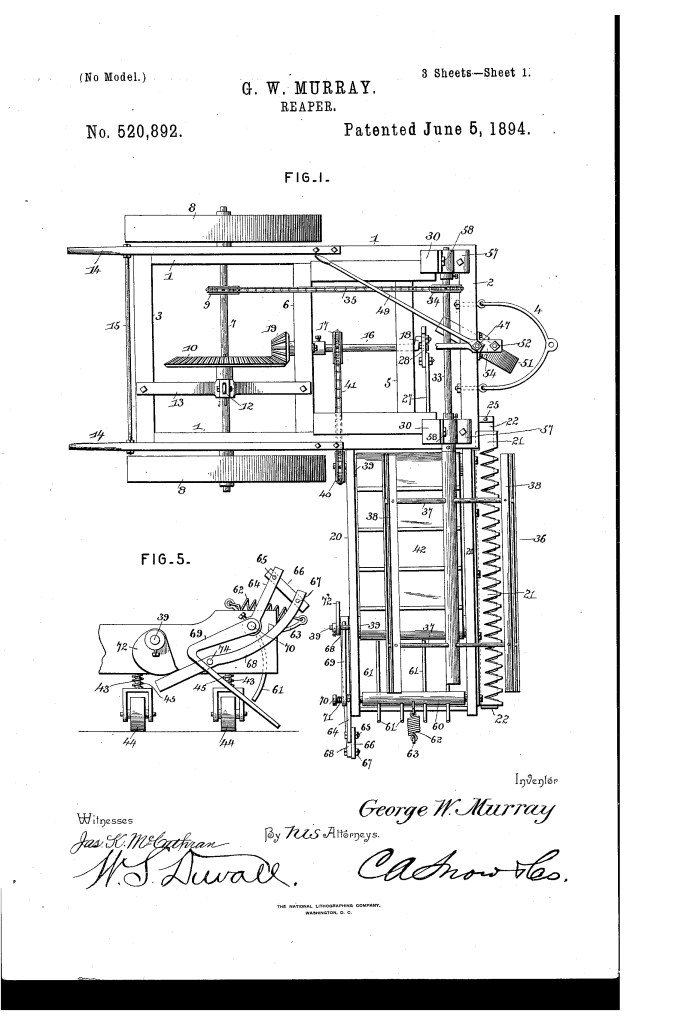

The machine is an oblong, wheeled frame that integrates the cutting, gathering, and automatic dumping mechanisms.

1. Cutting Mechanism

- Carrier Frame: Side frame-bars (20) extending from the main frame, equipped with stationary fingers (21).

- Cutter-Bar (Knife, 22): A knife mounted for rapid reciprocation between the fingers (21) to sever the grain.

- Drive: The knife is driven by a series of linkages: the main axle (7) drives a sprocket-chain (35) → to a longitudinal shaft (16) → which has a crank (18) → connected via a pitman (27) and link (28) → to a vibratory lever (24) → which is pivoted to the cutter-bar (22).

2. Gathering and Conveying

- Reel: A reel-head (36) with radial arms (37) and blades (38) is positioned to revolve over the carrier frame.

- Function: The reel feeds the standing grain to the cutter-bar and directs the cut material onto the carrier.

- Carrier (42): An endless apron or belt moves the cut grain toward the outer end of the carrier frame.

3. Automatic Bundle Dumping Mechanism (The Gaveler)

This mechanism uses the accumulated weight of the grain to trigger the release.

- Receiving Arms (61): Curved arms mounted on a transverse shaft (60) at the outer end of the carrier (42). They receive the grain delivered by the carrier.

- Yielding Support: The arms (61) are yieldingly supported by a coiled spring (62).

- Triggering: As grain accumulates, its weight eventually overcomes the tension of the spring (62), causing the arms (61) to yield and lower the shaft (60).

- Cam-Actuated Dump: The lowering of shaft (60) operates a linkage, causing a bell-cranked rocking lever (69) to be deflected by a pivoted bar (68) and move into the path of a revolving cam (72) carried by the carrier’s outer roll-shaft.

- Dumping: The cam (72) strikes the deflected lever (69), causing the shaft (60) to rotate suddenly, dumping the accumulated bundle (gavel) of grain onto the ground. The spring (62) then returns the arms to their normal receiving position until the next bundle accumulates.

4. Height Adjustment

- Frame/Cutter Height: A lever (54) at the front of the machine, connected to the main frame, allows the operator to depress the entire framework against the tension of coiled springs (53).

- Function: Depressing the frame causes the cutting mechanism to sever the grain nearer the butts (lower to the ground). Releasing the lever allows the springs to elevate the frame, severing the grain nearer the tops (higher cut). A locking standard (55) secures the lever at the desired height.

- Reel Height: The reel’s position can be adjusted by placing its metal bearings (57) into a series of transverse notches (56) in the vertical frame standards (30).

Historical Significance and the Inventor

This 1894 Reaper patent by George W. Murray completes a comprehensive set of mechanized farming tools he invented during that year.

- Mechanization of Harvest: Reaping small grains was, next to cultivation, the most labor-intensive farm task. Murray’s design was part of the ongoing evolution of harvesting machinery (following the work of McCormick and others) but focused on a simplified, affordable, and automatically dumping design suitable for small-to-medium Southern farms.

- Automated Gaveling: The automatic dumping mechanism (gaveler) is the patent’s most significant feature. Before this, bundles were often dropped in a continuous stream or required manual actuation. Murray’s weight-triggered, cam-actuated gaveler ensured that bundles were formed and dropped at consistent, predetermined intervals, making the subsequent task of collecting and binding the grain much easier and more efficient.

- The Inventor (George W. Murray): As an African-American inventor and agricultural reformer, Murray provided a complete set of solutions (stalk chopper, planter, fertilizer distributer, and now a reaper) that collectively offered the Black farming community the tools to achieve greater efficiency and economic viability during a challenging economic era.

Relation to Current Items

Murray’s reaper utilizes mechanisms that are fundamental to modern agricultural and material handling equipment:

- Weight-Triggered Release: The principle of using the accumulated weight of a product to trigger an action (the dumping cycle) is the core concept behind batch processing and automated sorting systems in material handling and food processing.

- Reciprocating Cutter: The reciprocating cutter-bar is the exact mechanism still used today in modern sickle-bar mowers and the main cutting component of combine harvesters for cutting grain and forage.

- Crank-and-Linkage Drive: The use of a shaft, crank, pitman, and lever to convert rotary motion into high-speed linear reciprocation is a classic mechanical engineering solution used in everything from internal combustion engines to industrial sewing machines.

- Adjustable Cutting Height: The ability to adjust the cutting height via a lever-and-spring system is functionally identical to the hydraulic header lift systems on modern combine harvesters, which allow the operator to instantaneously adjust the cutting height to match terrain and crop conditions.