Razor-Stropping Device (Henry Grenon, No. 554,867)

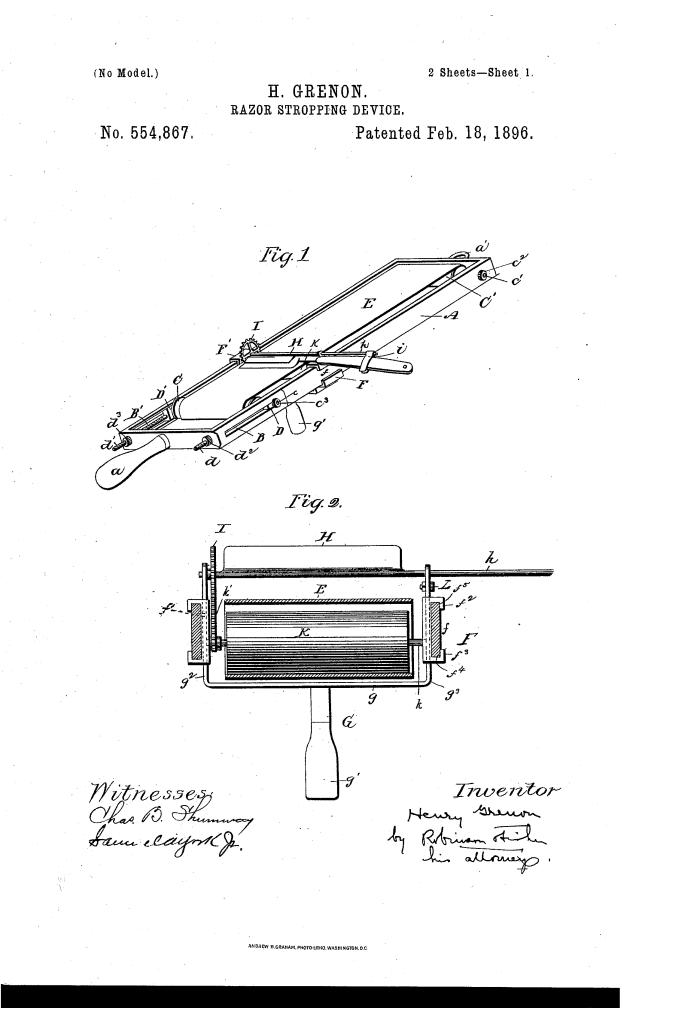

The patent by Henry Grenon of New Haven, Connecticut, describes a Razor-Stropping Device. The objective is to provide a mechanical device for stropping a razor that allows the razor to automatically turn (flip) on its back when the direction of motion is reversed, perfectly imitating the necessary technique of skilled hand-stropping.

Invention and Mechanism

The device is a self-contained, mechanical system that uses friction against the strop to flip the blade.

1. Frame and Strop

- Rectangular Frame (A): The main structure, with a handle (

) for gripping and a swivel eye (

) for mounting (though typically held by hand).

- Endless Strop (E): The leather strop extends over two rollers () fixed transversely within the frame.

- Tension Adjustment: One roller (

) is mounted on blocks (

) that fit into longitudinal mortises (B, B). Screw-nuts () allow the operator to adjust the blocks, thereby tightening or loosening the strop (E).

2. Carrier and Movement

- Travelers (F, F): These pieces fit over and embrace the sides of the frame (A), allowing them to move longitudinally along the frame.

- Carrier (G): A component with sides (

) that pass through recesses in the travelers (F, F), allowing the carrier to move vertically within the travelers.

- Operation: The user moves the carrier (G) back and forth along the frame (A) using its handle (

). A thumb-screw (L) adjusts the vertical position of the carrier to set the pressure of the blade on the strop.

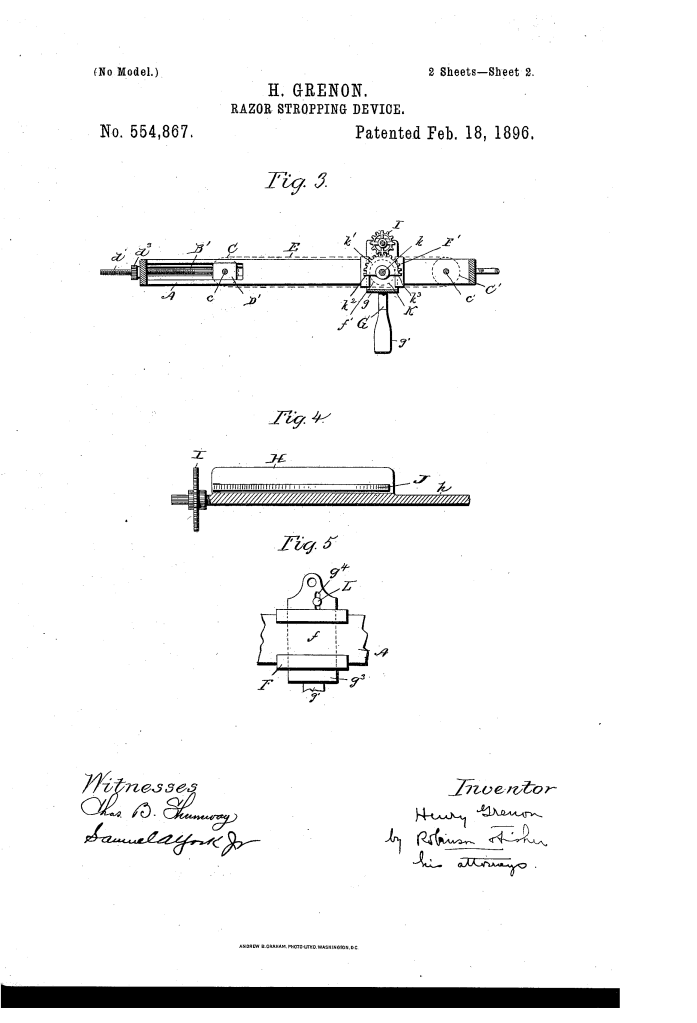

3. Automatic Flipping Mechanism (Key Innovation)

- Blade-Holder (H): A holder secured to a rod (

) that holds the razor blade securely with a curved metal spring (J).

- Gearing:

- Friction-Roller (K): A roller fixed to the side of the carrier (G) and designed to bear against the strop (E).

- Gear-Wheel (): Rigidly connected to the friction-roller (K).

- Cog-Wheel (I): Attached to the blade-holder rod (

) and meshes with the gear-wheel ().

- Operation:

- Forward Stroke: The carrier moves forward. The friction-roller (K) rotates in one direction against the strop. The gearing (

) translates this rotation, turning the blade-holder (H) and bringing the razor edge into contact with the strop.

- Reverse Stroke: The carrier moves backward. The friction-roller (K) is forced to rotate in the opposite direction. The gearing automatically reverses the blade-holder (H), flipping the razor to bring the opposite side of the blade into contact with the strop.

- Forward Stroke: The carrier moves forward. The friction-roller (K) rotates in one direction against the strop. The gearing (

- Safety Stops: The gear-wheel (

) is partially broken away (

) to form shoulders. These shoulders are adapted to strike the end of the carrier (G), thereby limiting the rotation of the friction-roller (K) to the necessary arc (180 degrees), preventing over-rotation and damage to the blade edge.

Historical Significance and the Inventor

Henry Grenon’s 1896 patent is a classic example of mechanizing a complex, high-skill domestic task for the mass market.

- The Razor Hone Problem: Maintaining a sharp edge on a straight razor requires a specific, alternating stroke where the blade is pushed edge-first and pulled spine-first. The user must manually “flip” the blade on its spine at the end of each stroke to hone the other side without dulling the edge. This required practice and concentration.

- Automation for the Layman: Grenon’s machine solved this problem mechanically. By coupling the translation motion (the pull/push) with the rotation of the blade (the flip) using a friction-drive system, he made professional-quality stropping accessible to anyone, reducing both the difficulty and the risk of ruining an expensive blade.

- The Inventor (Henry Grenon): Grenon, residing in New Haven, Connecticut, contributed to the late 19th-century boom in specialized consumer gadgets and tools designed to simplify household and personal maintenance tasks.

Core Concepts Utilized Today

Grenon’s razor stropping device uses kinematic and mechanical principles that are essential to modern motion control and personal care devices.

- Friction-Driven Actuation: The concept of using friction against a moving surface (the strop) to power a separate mechanical action (the blade flip) is a robust and simple principle used in various mechanisms where external drive power is unavailable, such as certain types of odometers and speed sensors that use wheel rotation to drive internal timing gears.

- Translational-to-Rotary Conversion (Self-Flipping): The primary concept of mechanically linking translational motion to controlled rotational motion is utilized in linear actuators and automated manipulators where the movement of a carriage must synchronize with the rotation of a tool head. More directly, the principle of a self-flipping mechanism is used in modern electric knife sharpeners and belt sanders where the angle of the grinding element is automatically maintained or reversed relative to the direction of travel.

- Gearing with Limit Stops: The use of gearing combined with mechanical shoulders () to prevent over-rotation is a fundamental safety and control mechanism. This design is common in actuators, clutches, and simple robotic joints where the rotation must be precisely limited (e.g., to 90 or 180 degrees) without complex electronic controls.

- Adjustable Pressure Mount: The thumb-screw (L) to adjust the vertical position of the carrier (G) to control pressure is analogous to the spring-tension adjustment on many modern hand grinders, belt sanders, and finishing tools.