Improvement in Ranges (Thomas A. Carrington, No. 180,323)

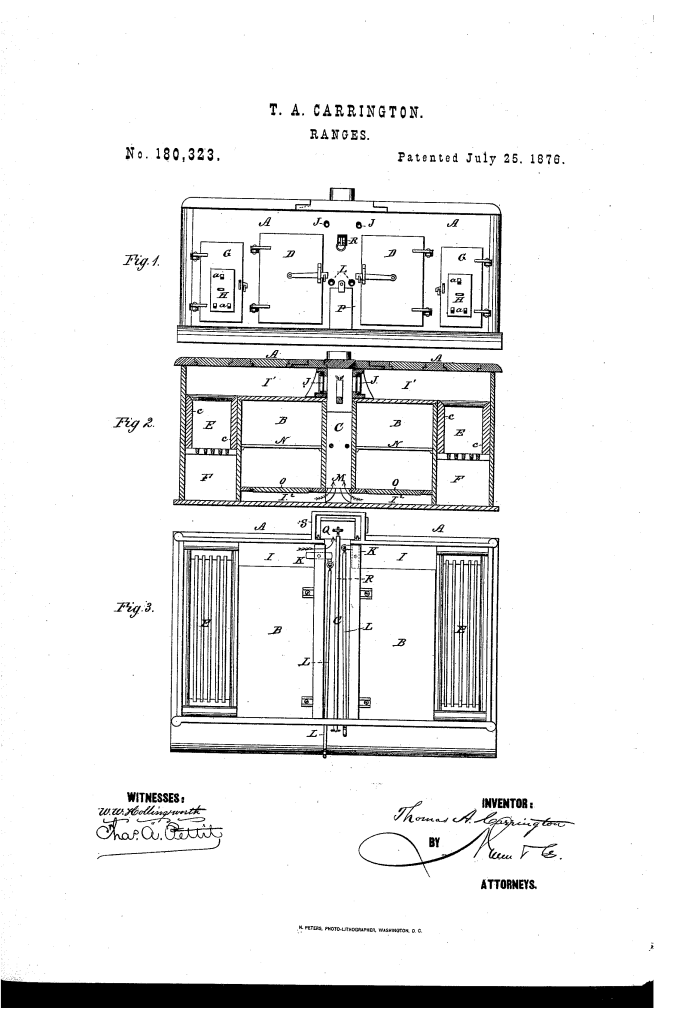

The patent by Thomas A. Carrington of Baltimore, Maryland, describes an improved Double Cooking-Range (Patent No. 180,323, 1876). The core of the invention is the symmetrical construction and arrangement of two full range units (ovens and furnaces) around a single central flue, allowing independent and versatile control of heat to each side.

Invention and Mechanism

The range is a double unit designed to maximize heat control and cooking capacity using a shared central exhaust.

- Symmetrical Dual Structure:

- The range consists of two symmetrical parts (A, A).

- Ovens (B, B): Two ovens arranged on opposite sides of a common central flue (C).

- Furnaces (E, E): Located outside of the ovens (between the oven and the outer wall of the range). Each side has its own furnace, provided with ash-pits (F) and draft-openings (G).

- Benefit: This duplicates the cooking capacity without needing two smoke-pipes or two chimney holes.

- Heat Control and Flue System (Key Innovation):

- Surrounding Chambers: Each oven (B) is built so that none of its sides directly touch the outer case or the furnace. Instead, it is surrounded by air/flue chambers:

- End chamber (I)

- Top chamber (

)

- Bottom chamber (

)

- Independent Heat Application: These chambers communicate with both the furnace (E) and the common central flue (C) and are controlled by separate dampers:

- Top Heat: Chambers (

) communicate with the central flue (C) through registers (J). Opening the registers directs heat over the top of the oven.

- Bottom Heat: Chambers (

) communicate with the central flue through dampers (K) on vertical pivots. Closing the top registers (J) and opening the bottom dampers (K) directs heat under the bottom of the oven.

- Top Heat: Chambers (

- Direct Heat: The chambers (I) communicate with the flue through openings (M). This route is used when both registers (J) and dampers (K) are closed.

- Surrounding Chambers: Each oven (B) is built so that none of its sides directly touch the outer case or the furnace. Instead, it is surrounded by air/flue chambers:

- Result: The system allows the heat to be variously applied at the top or bottom of each oven, and allows each side of the range to be operated and controlled independently of the other.

- Operation and Utility:

- By operating the two sides independently, different kinds of cooking may be carried on at the same time.

- Food can be transferred from one oven to the other to secure different temperatures for different parts of the cooking operation, enhancing results.

Historical Significance and the Inventor

Thomas A. Carrington’s 1876 patent is a significant contribution to the evolution of the cast-iron cooking range, which was the central appliance in the American home and commercial kitchen of the era.

- Maximizing Efficiency: The invention addressed the need for higher capacity and greater flexibility in cooking, which was increasingly demanded in large homes, hotels, and restaurants. By intelligently routing the heat from two furnaces into a single flue, Carrington maximized the available energy for cooking while solving the logistical problem of multiple exhausts.

- Precision Cooking: The ability to precisely control the heat distribution (top vs. bottom heat) in two separate ovens independently was a major step toward precision cooking. This level of control was essential for baking and roasting processes that require specific, sustained temperatures.

- The Inventor (Thomas A. Carrington): Carrington, residing in Baltimore, Maryland, contributed to the fierce competition among stove and range manufacturers to offer the most powerful, efficient, and versatile appliance for the domestic and commercial markets.

Core Concepts Utilized Today

Carrington’s principles of thermal management and zoned heating are fundamental to modern commercial cooking and HVAC systems.

- Zoned Thermal Control: The design of two independent furnaces/ovens operating within one case but sharing a common exhaust is the conceptual basis for modern commercial banked cooking systems and zoned HVAC systems. These systems allow different sections (zones) to be heated to different temperatures or operated on independent schedules without needing separate infrastructure.

- Heat Routing and Dampers: The use of surrounding air chambers (

) and dampers (K) and registers (J) to direct hot air flow over or under a cooking chamber is the core principle of convection cooking and modern forced-air ovens. By controlling the flow path, the appliance achieves specific cooking modes (e.g., direct heat vs. circulating heat).

- Thermal Isolation: The intentional design to separate the ovens from the outer casing and the furnaces by air chambers is an early form of thermal isolation and insulation, which is crucial in all high-efficiency ovens and furnaces today to prevent heat loss and ensure uniform cooking temperature.