Railroad-Switch (Charles V. Richey, No. 587,657)

The patent by Charles V. Richey of Washington, D.C., describes certain new and useful Improvements in Railroad-Switches (Patent No. 587,657, 1897). The invention focuses on providing an automatic railroad-switch system that can be opened remotely by the engineer before the train reaches it and closed automatically after the entire train has passed.

Inventor Background: Charles V. Richey

Charles V. Richey was an African-American inventor who focused heavily on railway safety and convenience mechanisms. He was a prolific inventor, also holding patents for a different type of railroad switch (No. 592,448) and the Fire-Escape Bracket (No. 596,427). His work addressed the critical need for automation and remote control in the late 19th-century rail industry.

Invention and Mechanism

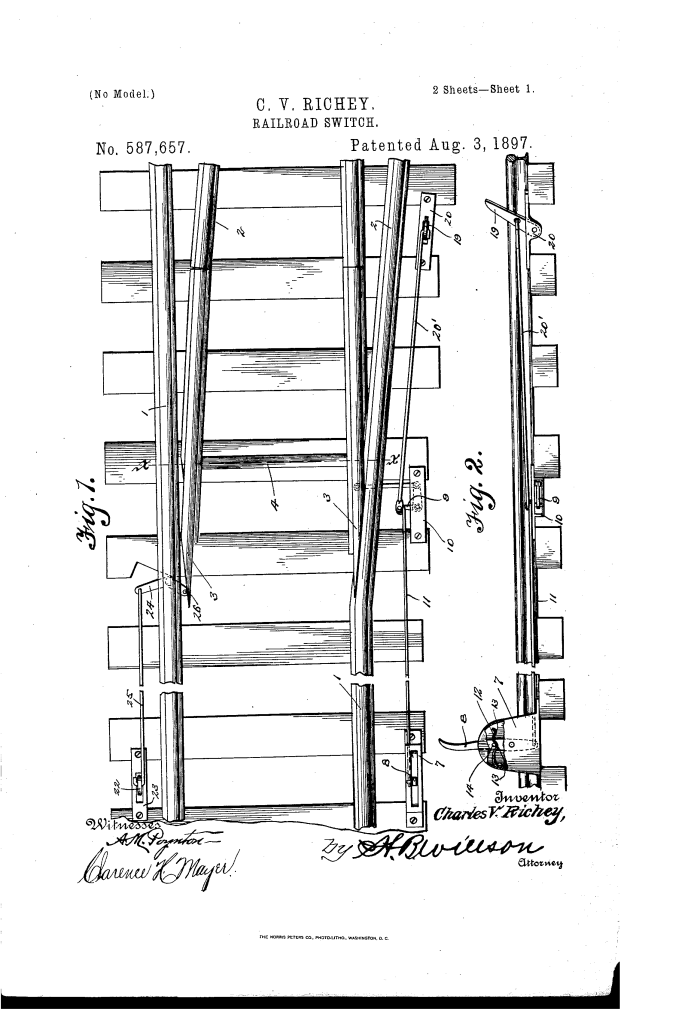

The system combines track-side levers with unique car-mounted tripping arms for controlled, sequential operation.

1. Remote Switch Opening (Engineer Actuated)

- Trip-Lever (8): A lever pivoted in a track-side stand (7).

- Linkage: The trip (8) is connected via a pitman (11) and a bell-crank lever (9) to the switch-tongues (3). Actuating the trip moves the switch.

- Locomotive Arm (17): A long arm pivoted to a bracket (15) on the front of the locomotive, controllable by the engineer via a cord (18) leading into the cab.

- Function: When the engineer pulls the cord, the arm (17) is raised. When the arm strikes the trip (8), it automatically opens the switch (moves the switch tongues to the siding position).

- Anti-Vibration Lock: A spring (12) and pin (14) lock the trip in position to prevent accidental movement from track vibration when a train is passing on the main line.

2. Automatic Switch Closing (Train Actuated)

- Closing Arm (19): A lever (arm 19) is pivoted in track-side brackets (20) and is connected by a link (

) to the bell-crank lever (9) that controls the switch.

- Rear Car Arm (21): A hinged arm (21) is secured to the rear end of the rear car of the train and projects laterally.

- Function: As the rear of the train passes the closing arm (19), the hinged arm (21) on the last car engages arm (19) and closes the switch. This ensures the switch automatically reverts to the main track position after the entire train has cleared.

- Differential Arm Lengths: The closing arm (19) is shorter than the opening arm (trip 8), and the rear-car arm (21) is shorter than the locomotive arm (17). This differential sizing prevents the locomotive’s opening arm (17) from accidentally striking the closing arm (19) and prevents the closing arm (21) from accidentally striking the main opening trip (8).

3. Reverse Traffic Safety

- Reverse Trip (22): A separate trip arm is placed on the opposite side of the track.

- Function: This secondary trip is connected to a bell-crank lever (24) that closes the switch when a train backs out from the switched track, preventing movement into a potentially misaligned switch.

Concepts Influenced by This Invention

Richey’s design influenced subsequent railway and control systems by pioneering highly reliable sequential, car-actuated automation using differential sizing.

- Sequential Car-Actuated Systems: The most significant influence is the reliance on different cars in the train (locomotive vs. rear car) to perform different, necessary, and sequential actions (open switch vs. close switch). This influenced the design of early mechanical systems for sequencing operations based on a train’s passage.

- Remote Opening and Local Closing: The strategy of using a remote operator input (engineer’s cord) for activation but relying on a passive mechanical trip (rear car arm 21) for deactivation influenced the philosophy of control: centralized command for safety opening, decentralized, reliable automation for safety closing.

- Differential Sizing for Selectivity: The technique of making the physical tripping arms of different lengths (17 vs. 21) to ensure each arm interacts only with its specific, intended track-side target (trip 8 vs. arm 19) is a clever mechanical principle used in sorting and indexing machinery to prevent interference between parallel tracks or actuators.

- Antifriction Bearings: The use of antifriction-balls (5) in the switch-tongue linkage to reduce wear and resistance to movement influenced the requirement for low-maintenance, smooth-acting components in all heavy-duty trackwork.