Hand-Punching Machine (Enos W. Stewart, No. 362,190)

The patent by Enos W. Stewart of Kalamazoo, Michigan, describes an improvement in Hand-Punches for Metals (Patent No. 362,190, 1887). The invention is a high-leverage industrial tool designed to perforate metal sheets “quickly and perfectly.” It is notable for its use of a toggle-joint mechanism, which provides the immense force required to punch through iron or steel using only manual power.

Inventor Background: Enos W. Stewart

Enos W. Stewart was an African American inventor based in Kalamazoo, Michigan. His work in the 1880s focused on heavy mechanical devices—specifically tools that integrated multiple mechanical principles to amplify human strength. Stewart’s punching machine reflects the industrial needs of the era, where blacksmiths, carriage makers, and ironworkers required tools that could perform repetitive, high-strain tasks with precision. His designs often emphasized “part consolidation” and ease of maintenance, such as the removable punch-bits used in this machine.

Invention and Mechanism (Simplified)

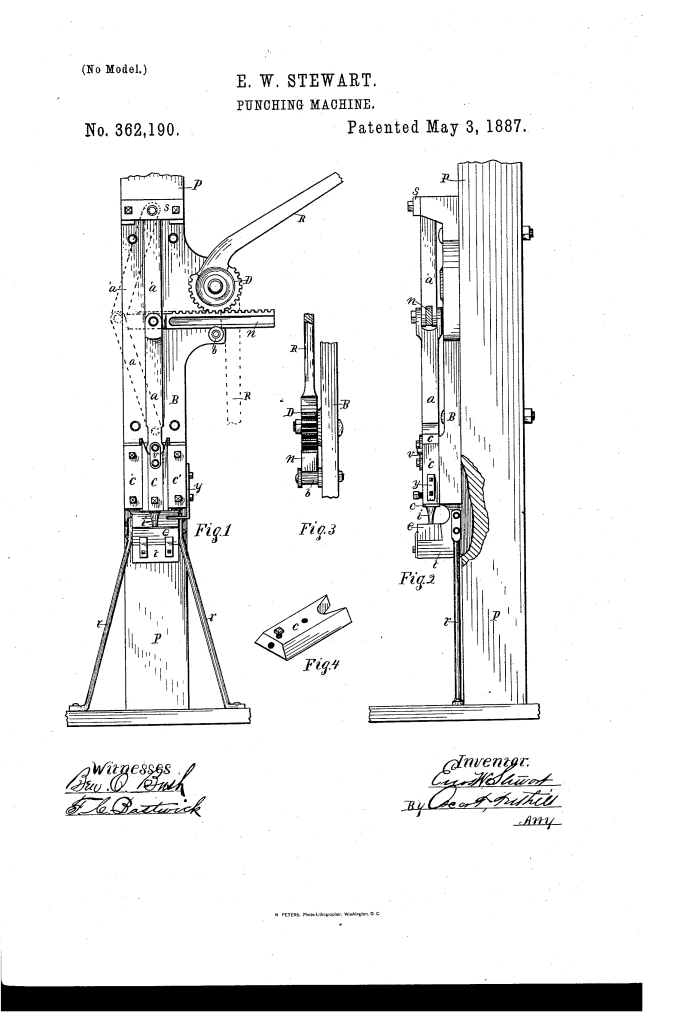

The machine uses a gear-driven rack to actuate a “toggle” or “elbow” joint, creating a massive downward thrust.

1. The Toggle-Joint (a, a)

- The Elbow Joint: Two heavy metal toggle-bars (a, a) are pinned together at a central joint. The top bar is anchored to the frame, and the bottom bar is attached to the punch-head (V).

- Mechanical Advantage: A toggle-joint works by applying force to the central pivot. As the bars are pushed into a straight vertical line, the downward force becomes nearly infinite at the moment of straightening.

2. The Gear and Rack Drive (N, D)

- Toothed Rack (N): Attached to the central joint is a horizontal bar with teeth, known as a rack (N).

- Segmental Pinion (D): This rack is in gear with a segmental pinion (D) (a gear that is only a partial circle).

- The Lever (R): The operator pulls or pushes the lever (R), which turns the pinion and moves the rack horizontally.

3. The Punching Action

- Punch-Block (O) and Ways (C): The punch-bit is attached to a block that slides vertically within precision-machined ways (C).

- One-Stroke Operation: Stewart designed the linkage so that a single up-or-down stroke of the lever drives the punch through the metal. As the rack moves the toggle-joint toward the center, the punch is forced down; as the lever continues its stroke past the center, the toggle begins to pull the punch back up, clearing the hole automatically.

4. The Frame and Stability

- Frame (B) and Post (P): The entire machine is bolted to a sturdy vertical post (P).

- Stay-Rods (r): To prevent the machine from twisting under the extreme pressure of punching, stay-rods (r) firmly anchor the frame in place.

Concepts Influenced by This Invention

Enos W. Stewart’s punching machine influenced the development of high-leverage manual tools and mechanical advantage engineering.

- Toggle-Action Pressing: The use of the toggle-joint to generate extreme force from a small input is the foundation of modern toggle presses used in jewelry making, small-scale stamping, and electrical connector crimping.

- Compound Mechanical Advantage: By combining two different mechanical systems—a rack and pinion (for translation) and a toggle-joint (for force multiplication)—Stewart demonstrated a sophisticated approach to machine design that maximized human efficiency.

- Linear Reciprocation: The use of “ways” to ensure a tool moves in a perfectly straight line is a fundamental principle in all machine tools, from drill presses to CNC mills.

- Redundant Motion Efficiency: Stewart’s “over-the-center” toggle design allowed the operator to punch and retract in one continuous motion, a logic still used in modern high-speed industrial staplers and punch-presses.