Potato-Digger (Francis J. Wood, No. 537,953)

The patent by Francis J. Wood of Greenville, Michigan, describes an improved Potato-Digger. The invention focuses on a novel mechanism for controlling the depth of the shovel and, critically, for imparting a complex, adjustable shaking motion to the grate (separator) to efficiently separate potatoes from the earth.

Invention and Mechanism

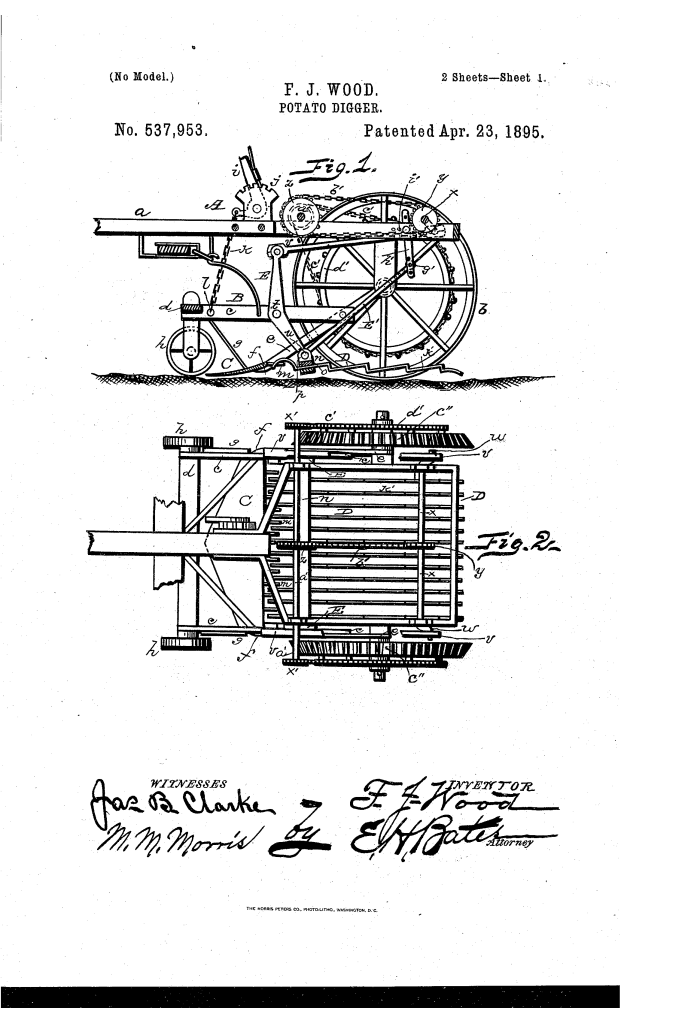

The potato digger is a wheeled, framed machine that separates potatoes from soil using a combination of a depth-adjustable shovel and a mechanically actuated grate.

1. Depth Adjustment and Main Frame

- Main Frame (A): The main chassis, supported by the tongue (a) and transporting wheels (b).

- Lower Pivoted Frame (B): A sub-frame arranged below the main frame and pivoted at its rear end to the main axle. The shovel (C) is secured to the front of this lower frame.

- Depth Control: The forward end of the lower frame (B) is provided with caster wheels (h) (or gage wheels) to ride on the ground. A hand lever (e′), a toothed rack (j) secured to the main frame, and a chain (k) are used to raise or lower the forward end of the pivoted frame, thereby controlling the depth of the shovel (C) in the ground.

2. Shaking/Separating Grate (D)

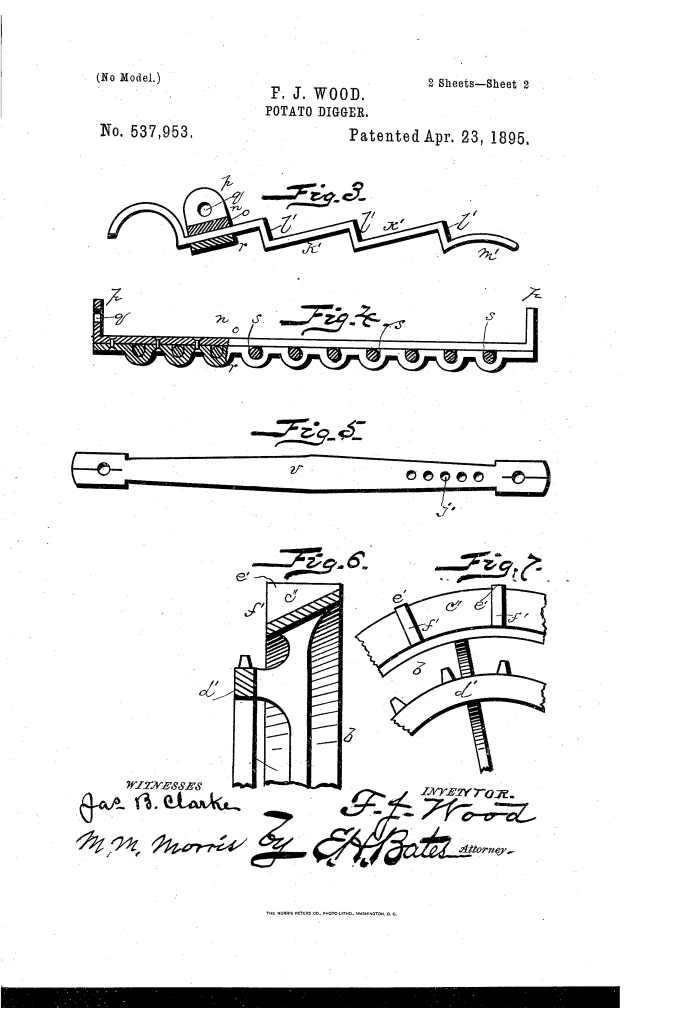

- Grate Bars: The separator consists of a series of grate bars (D) of a peculiar construction, arranged directly behind the shovel (C).

- Construction: Each bar is arched at the front, has inclined portions (k), and is provided with offsets (l) presenting shoulders that force the potatoes rearwardly and off the grate.

- Support: The bars are held together by a cross bar (n) consisting of two bolted or riveted sections (upper o and lower r) with grooves (s).

3. Actuation and Adjustable Shaking Motion

The digging and separating action is powered by the ground wheels (b).

- Drive Train: The transporting wheels (b) have sprocket rims (d′) connected by chains (c′) to a front transverse shaft (a′). This shaft drives the rear transverse cranked shaft (x) via another chain (b′).

- Shaker Linkage: The cranked end (w) of the shaft (x) drives a pitman (v).

- The pitman (v) drives an angular pivoted bar (E), which is pivoted at its center (t) to the lower frame.

- The lower end of the bar (E) is pivoted to the grate’s cross bar (o).

- Adjustable Support Rod (E′): An inclined rod (E′), rigid with the grate, has a double pivotal connection (via a short bar h′) to the lower frame (B). This rod and the short bar are provided with multiple perforations for fine-tuning.

- Function (Complex Motion): The combination of the angular pivoted bar (E) and the adjustable support rod (E′) gives the grate a combined forward, backward, and upward movement. The complex motion separates the potatoes from the earth and moves them rearward.

- Fine-Tuning: The perforated connections allow the grate movement to be adjusted from an almost horizontal movement (for gentle agitation) to a violent up and down motion (for breaking wet sod), depending on which perforation the short arm (h′) is connected to.

Historical Significance and the Inventor

Francis J. Wood’s 1895 patent is part of the ongoing mechanization of farming, specifically addressing the intensive labor required for potato harvesting.

- Mechanizing Root Crops: Digging root crops like potatoes was extremely labor-intensive and manual before effective mechanical diggers were developed. Early diggers often failed to adequately separate the crop from heavy, wet soil, leaving many potatoes buried or bruised.

- Focus on Separation: Wood’s invention is significant for its intense focus on the separation mechanism. The shovel’s depth control and the elaborate linkage for the grate’s complex, customizable shaking motion were designed to maximize separation efficiency under various soil conditions (from light soil to heavy, wet earth).

- Adjustability: The inclusion of multiple adjustment points for the shaker linkage and the ability to change the grate’s action demonstrates an understanding that a successful mechanical digger must be adaptable to different field conditions—a necessary trait for any durable agricultural machine.

Relation to Current Items

Wood’s potato digger utilizes principles still central to modern agricultural machinery:

- Eccentric/Crank-Driven Shakers: The use of a cranked shaft (x) driving a pitman (v) to generate reciprocal or shaking motion is the standard mechanism for all modern vibrating screens, sorting tables, and shaker pans , including those in modern potato harvesters.

- Integrated Depth Control: The use of a lever and linkage to control the working depth of a ground-engaging tool (like the shovel) is the conceptual precursor to the hydraulic depth control systems found on nearly all modern tractor-drawn implements, which allow the operator to adjust depth on the fly.

- Adjustable Linkages: The ability to tune the type and violence of the shaking motion through multiple adjustment holes in the linkage is analogous to the adjustable dampening and spring settings found on modern harvester suspensions and separating beds, allowing farmers to quickly change settings for different crop and soil types.

- Transport Wheel Treads: The uniquely shaped lugs on the transporting wheels, designed to gain a better grip on the ground only when the wheels slip, are a conceptual antecedent to specialized traction treads and self-cleaning tire designs used on agricultural and construction equipment to maintain purchase without excessive soil compaction.