Postal Machine (William Barry, No. 585,075)

The patent by William Barry of Syracuse, New York, describes a comprehensive Postal Machine (Patent No. 585,075, 1897). The invention covers numerous integrated mechanisms for postmarking and canceling mail, aiming to produce a machine that is sure, effective, and rapid while handling letters of various sizes and thicknesses without jamming or excessive wear.

Inventor Background: William Barry

William Barry was an inventor focused on mechanical automation for the postal service and commercial processing. His sustained work in the 1890s focused on creating high-speed, reliable machinery for processing mail, solving the crucial logistical challenge of efficiently handling massive volumes of correspondence. His designs are notable for their emphasis on minimizing wear and making repair quick and easy.

Invention and Mechanism

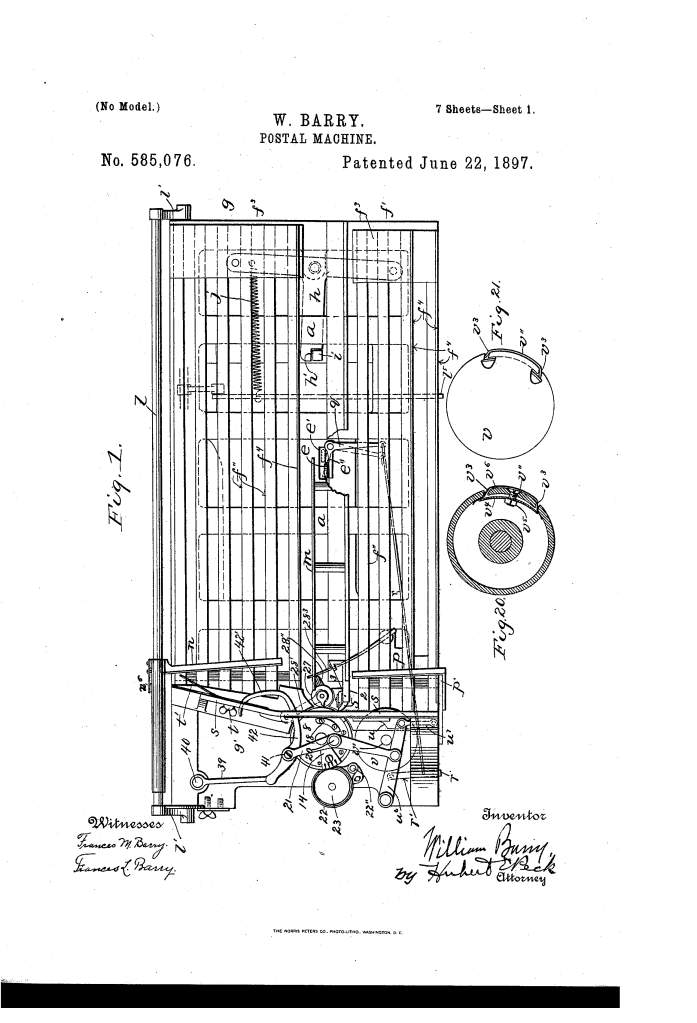

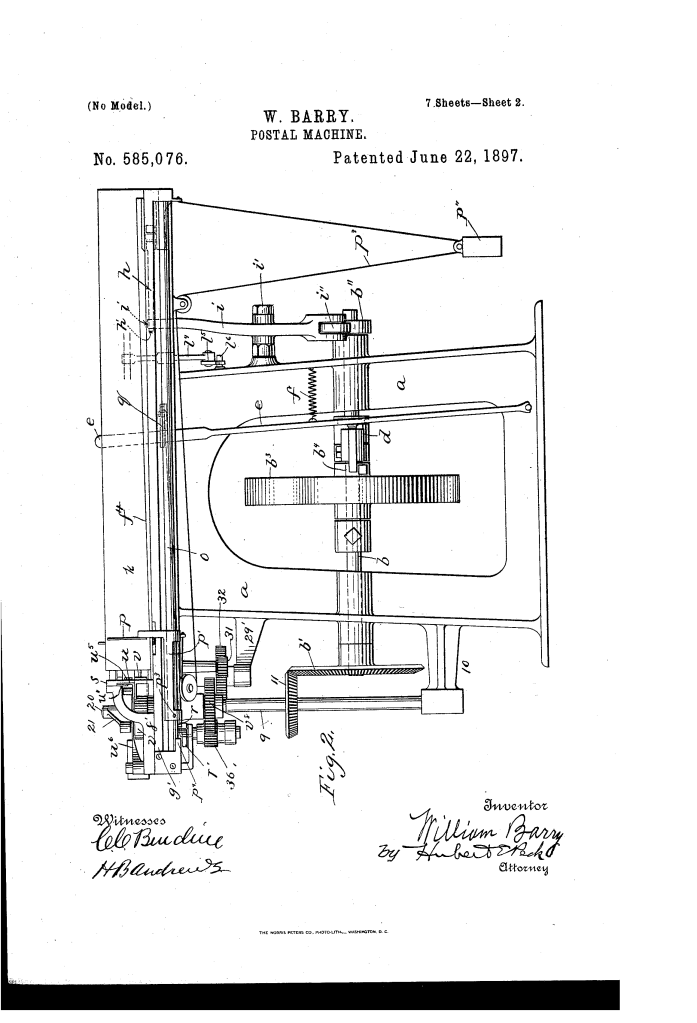

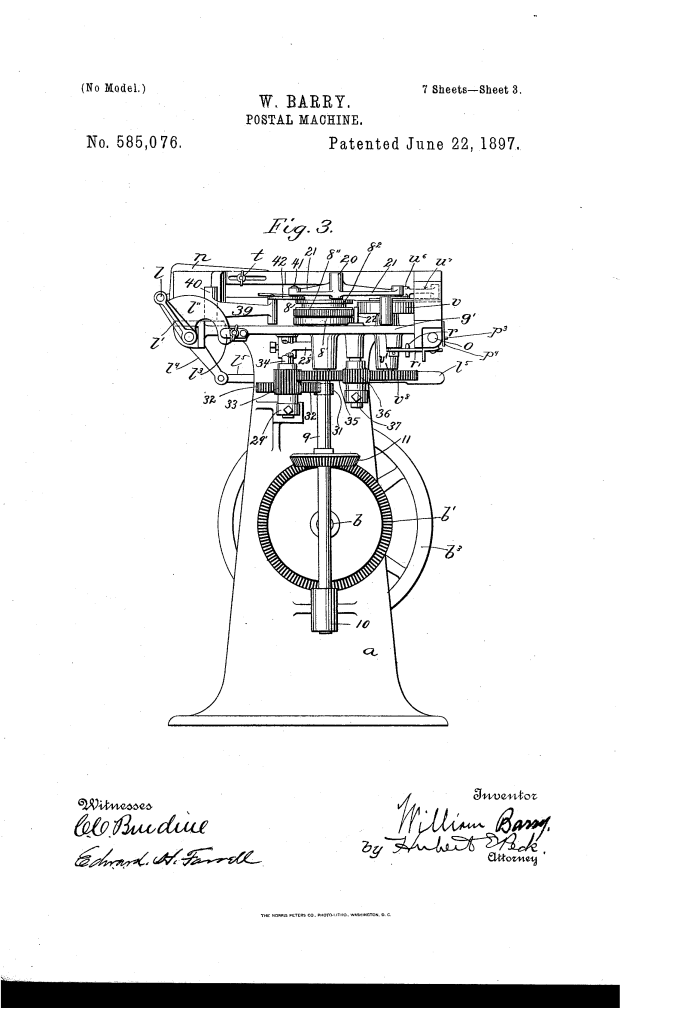

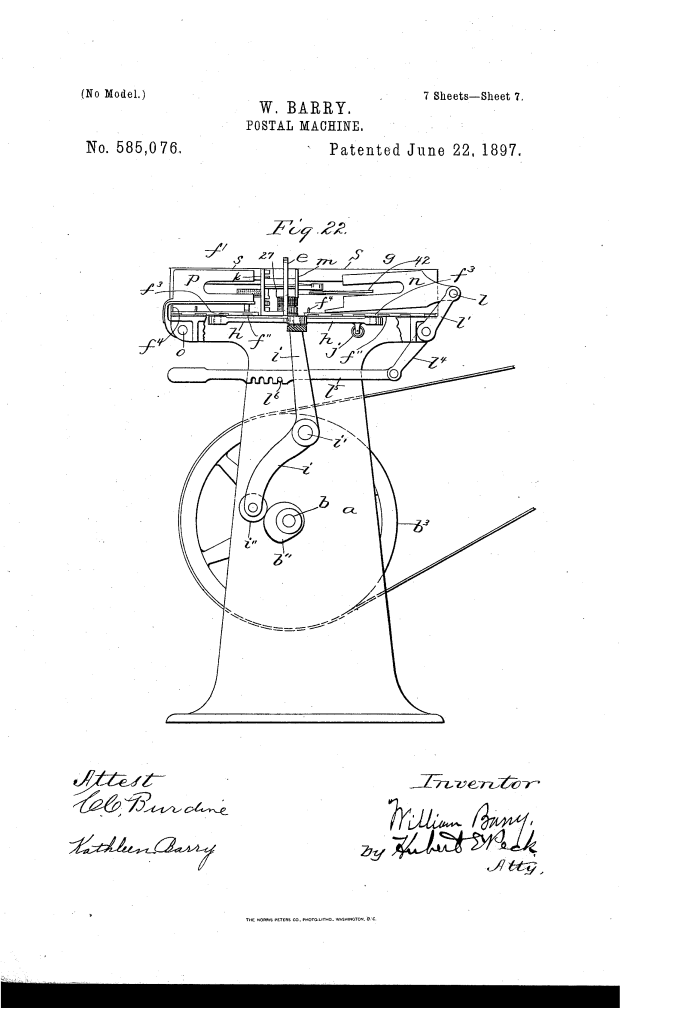

The machine is an intricate, synchronized system covering five stages: facing/stacking, feeding, printing, inking, and stacking the finished mail.

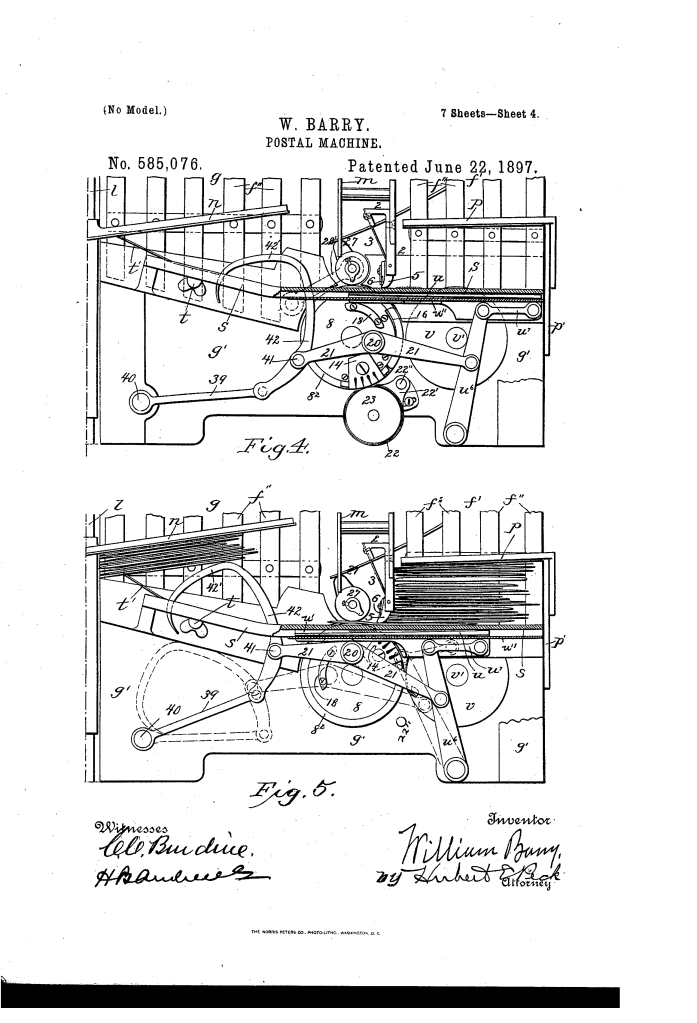

1. Mail Feeding (Key Innovation: Opposite Reciprocation)

- Reciprocating Floors: The feedway and receiving-way floors are connected by a lever system to a cam and are driven to reciprocate longitudinally in opposite directions.

- Function: The slow forward movement on the feedway pushes the letters toward the printing head, while the quick, opposing return movement on the receiving-way feeds the finished stack outward. This ensures continuous, non-crowded flow.

- Auxiliary Rotary Feeder (): A horizontal, rotating roll projecting into the feedway.

- Function: This roll acts in conjunction with the main reciprocating feeder to line up the letters against the inner guide and help overcome the initial inertia of each letter, easing the strain on the main feeder.

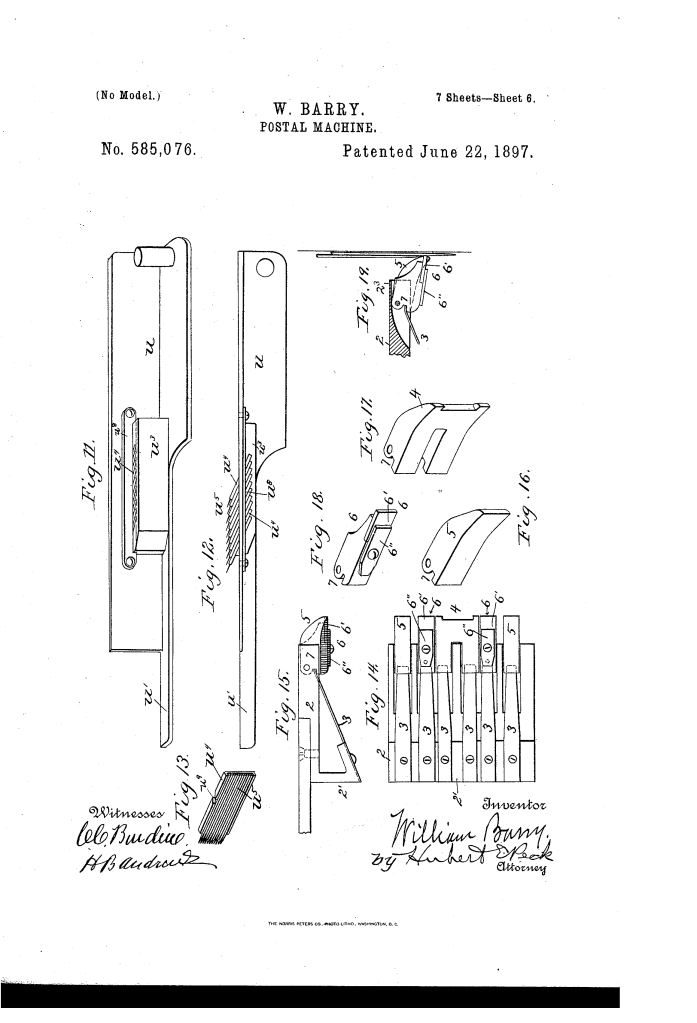

2. Feeder and Separation

- Sectional Feeder (53): A gripping block made of multiple, independently movable plates with sharp points.

- Function: This flexible, sharp-pointed surface ensures a firm grip on uneven or varied-thickness mail without damage.

- Timed Lateral Thrust (Nose 67): The feeder is forced inwardly toward the letters by a spring-stop at the beginning of its stroke.

- Function: This timed inward thrust ensures the feeder grasps the letter by its end and pulls it past the separator, avoiding bending or tearing the mail.

- Adjustable Separator Fingers (Key Innovation): A series of spring-held fingers (34) extend across the discharge throat. Some fingers are rounded (convexed) to guide the letter, while others terminate in a sharp edge (using a reversible plate) to catch and hold back the ends of the letters behind the one being fed.

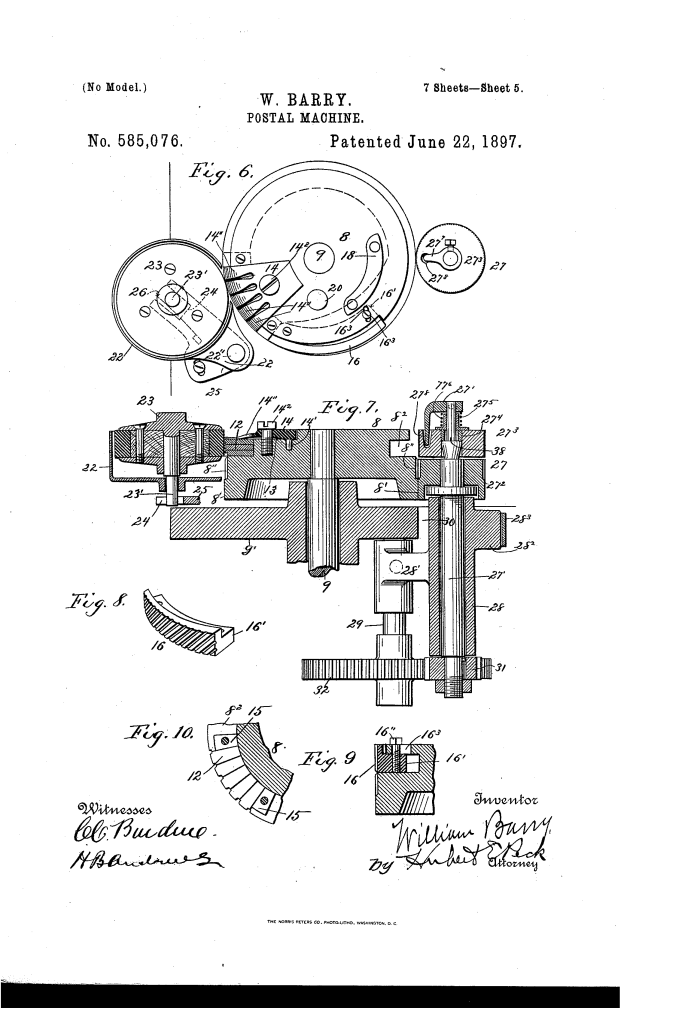

3. Printing Mechanism (Timed Tension and Yielding)

- Timed Tension Control: A cam (112) on the printing-roll shaft intermittently relieves the tension on the impression-roll as the letter enters, and then increases it to maximum pressure precisely at the printing point, guaranteeing a clear impression on variable-thickness mail.

- Yielding Impression Roll (50): Features a universal joint (or ball-joint) that allows the roll to rock laterally (yield independently of its shaft).

- Function: This ensures the impression surface remains parallel to the printing surface, adapting to uneven mail to always present a firm backing.

- Inking Isolation: The printing-roll’s edges are reduced and beveled, ensuring the inking roller (23) only contacts the type, preventing ink from smearing the rest of the letter or getting onto the impression roll.

4. Stacking and Containment

- Stacker (131): A horizontally-swinging pusher connected to the printing wheel by an eccentric drive. It moves in an elliptical path to push each letter back and laterally align it against the guide in the receiving-way.

- Removable Tray (140): The receiving floor is a removable tray, which is part of the reciprocating system, allowing for fast batch removal.

- Swinging Shield (98): A flexible shield suspended over the inlet of the receiving-way to prevent letters from “flying up” when discharged.

Concepts Influenced by This Invention

Barry’s machine is a conceptual cornerstone for modern high-speed industrial processing, influencing systems that require precision handling of disparate, flexible items.

- Dynamic Pressure Control: The cam-actuated, timed tension relief for the printing rolls influenced the design of industrial feeders that use dynamic pressure control to prevent crushing or tearing fragile materials (like paper or thin plastics) during the feeding cycle.

- Opposite Reciprocating Conveyance: The unique system of using a single drive to move parallel conveyor floors simultaneously but in opposite directions influenced the design of sophisticated sorting and indexing conveyors where synchronized, non-clogging material transfer between two adjacent zones is required.

- Integrated Feeder and Separator: The concept of having the feeder mechanism (53) and separator fingers (34) work in direct, timed opposition (with the feeder pulling past the spring-held separator) influenced the engineering of all modern singulation devices (for separating mail, currency, or products).

- Yielding Impression Surfaces: The impression roll’s use of a universal joint or rocking mount to maintain parallelism against uneven objects influenced the design of automated equipment requiring adaptive tooling surfaces .