Portable Screw-Press (John P. Parker, No. 318,285)

The patent by John Percial Parker of Ripley, Ohio, describes certain new and useful Improvements in Portable Screw-Presses (Patent No. 318,285, 1885). The invention is a heavy-duty, modular press designed primarily for pressing tobacco into hogsheads (large barrels) but adaptable for similar agricultural or industrial purposes. The design focuses on high mechanical advantage, portability, and an efficient workflow.

Inventor Background: John P. Parker

John Percial Parker (1827–1900) was a prominent African-American inventor, industrialist, and abolitionist. Born into slavery and later buying his own freedom, Parker became a master molder and established the Phoenix Foundry in Ripley, Ohio.1 He was a prolific inventor, particularly in the field of agricultural machinery. Beyond his industrial success, Parker was a celebrated “conductor” on the Underground Railroad, helping hundreds of enslaved people cross the Ohio River to freedom.2 His patents, including several for tobacco presses and soil pulverizers, demonstrate his deep technical expertise and his role as a leading black industrialist of the 19th century.3

Invention and Mechanism (Simplified)

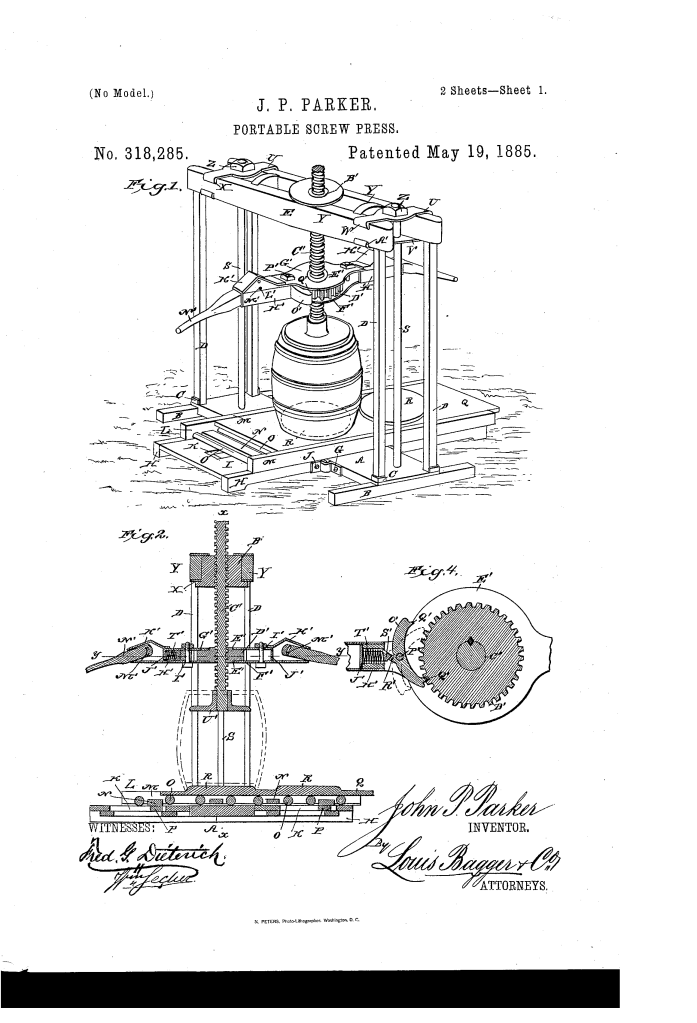

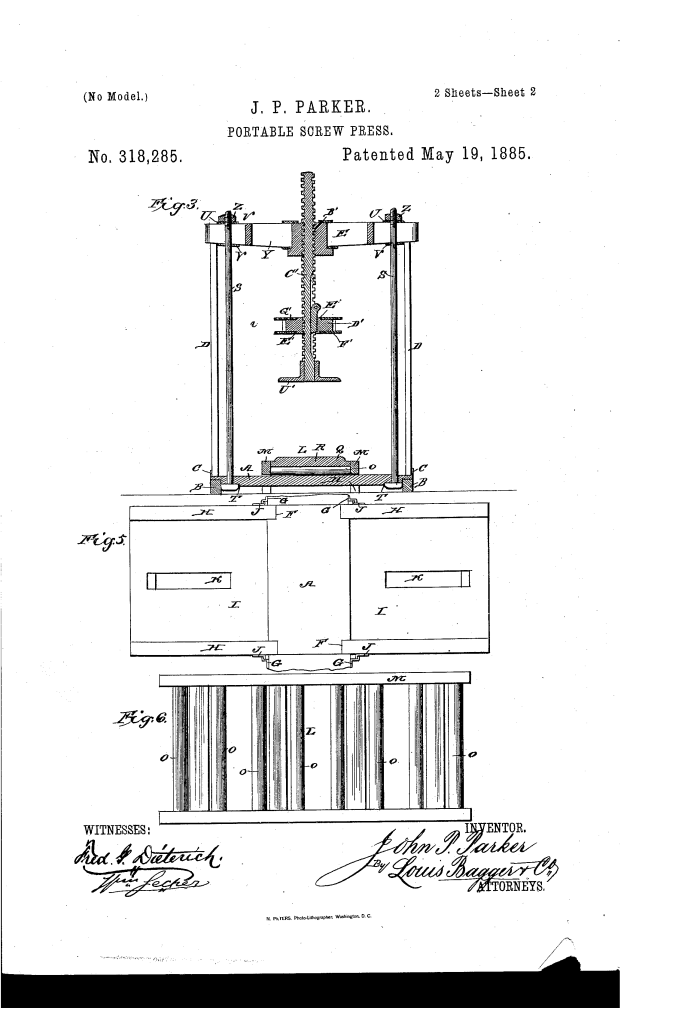

The press uses a large central screw driven by a ratcheting lever system, mounted on a frame that can be entirely disassembled for transport.

1. The Modular Frame and Bed

- Base (A) and Bed Extensions (I): The press sits on a central base (A). It features bed-extensions (I) that fit into notches (F) and are secured by interlocking flanges or “lips” (G and J).

- Props (D) and Top Piece (E): Vertical props (D) support a heavy transverse top piece (E). These are held in place by vertical rods (S) that run from the base to the top. When the nuts (Z) on these rods are tightened, the entire frame is clamped endwise, creating a rigid structure that can still be easily taken apart.

2. The Carriage and Workflow (Key Innovation)

- Carriage (L) and Platform (Q): A wheeled carriage travels along the bed extensions. A platform (Q) with circular blocks (R) for holding barrels sits on top of this carriage.

- Function: This allows for a continuous workflow. One hogshead can be filled with tobacco while another is currently being pressed under the screw. Once pressed, the barrel is simply slid out on the carriage, and the next one is moved into place.

- Stops (P): Downward lugs or stops prevent the carriage from rolling off the ends of the bed.

3. Ratchet and Lever Power Mechanism

- Cogged Nut (D’) and Double Pawl (O’): The central screw (C’) is moved by a cogged or notched nut. This nut is encased by two plates (F’, G’) that hold a double-acting pawl (O’).

- Function: A spring-actuated bolt (S’) allows the pawl to be tilted to either side. This enables the operator to turn the nut in either direction—screwing the press down to apply pressure or up to release it—by simply rocking the levers (N’) back and forth.

- Inclined Levers (N’): The levers are pivoted so they depend at an angle. This ensures they remain within reach and convenient to manipulate regardless of whether the screw is at its highest or lowest point.

Concepts Influenced by This Invention

Parker’s portable screw-press influenced subsequent industrial designs by pioneering modular heavy-duty construction and high-efficiency linear workflow.

- Modular Industrial Design: The concept of a high-pressure machine that utilizes tension rods (S) to clamp structural members (props and beams) together—allowing for both extreme rigidity and easy disassembly—is a fundamental principle in modern portable industrial equipment and temporary structures.

- Linear Assembly/Processing Workflow: The use of a sliding carriage and bed-extensions to allow simultaneous filling and pressing operations influenced the layout of early factory production lines and bulk material processing stations.

- Ergonomic Ratchet Actuation: The specific design of the inclined, pivoting levers combined with a reversible double-pawl ratchet influenced the development of manual heavy-lifting tools (like industrial jacks and winches), where the operator’s physical reach must be considered across a wide range of mechanical motion.

- Agricultural Mechanization: Parker’s inventions were critical in the post-Civil War era for professionalizing and mechanizing the tobacco industry, moving it away from crude, stationary manual presses toward efficient, portable machinery.

Would you like me to look into John P. Parker’s other patents, such as his soil pulverizer or his earlier 1884 screw-press?