Pneumatic Tire (Norman Jackson, No. 1,384,134)

The patent by Norman Jackson of Washington, D.C., describes an advanced Pneumatic Tire (Patent No. 1,384,134, 1921). This invention focuses on a “fail-safe” inner tube construction designed to eliminate the immediate danger and inconvenience of a flat tire. Jackson’s primary innovation was the use of an annular series of sectional air tubes combined with a set of folded emergency tubes that automatically inflate to fill the gap if a main section is punctured.

Inventor Background: Norman Jackson

Norman Jackson was an African American inventor based in the District of Columbia during the early automotive boom of the 1920s. At a time when tires were highly susceptible to punctures from unpaved roads and debris, Jackson’s invention provided a sophisticated engineering solution to a common and frustrating problem. His work demonstrates a mastery of pneumatic systems and compartmentalized design, moving away from the “single-tube” vulnerability that characterized most tires of his era.

Key Mechanical Components & Functions

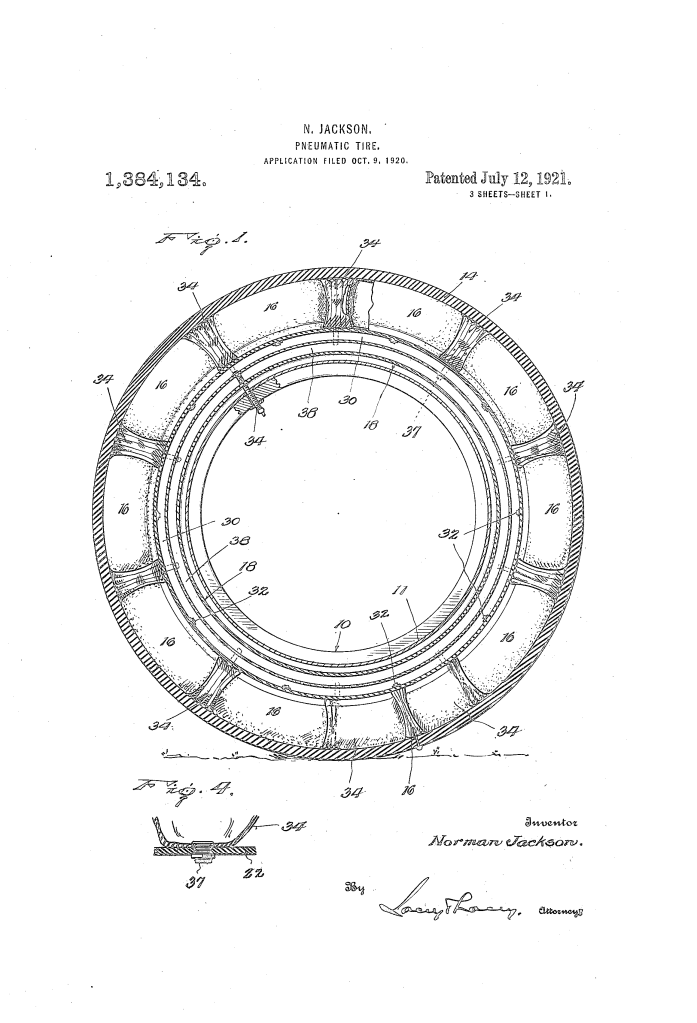

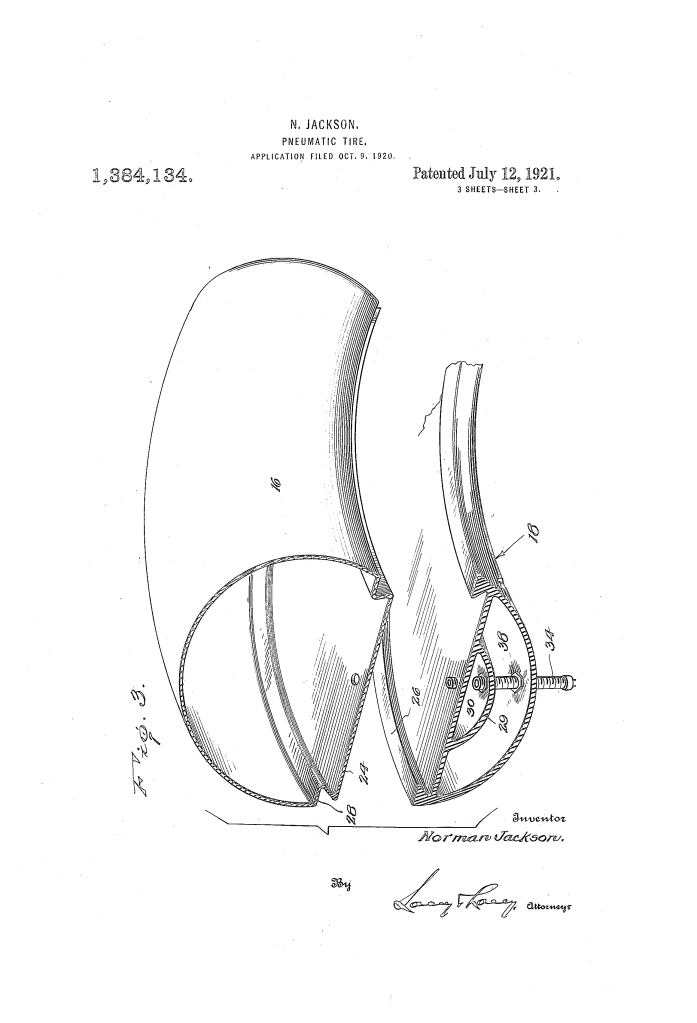

The tire is composed of a complex internal structure housed within a standard tire casing.

1. The Sectional Main Tubes (16)

- Arcuate Design: The tire contains ten independent, arcuate (curved) sections (16).

- Self-Sealing Architecture: These sections are mounted on a flat-topped annular tube (18).

- Function: Because the air is divided into ten separate chambers, a single puncture only affects 10% of the tire’s volume, preventing a total blowout.

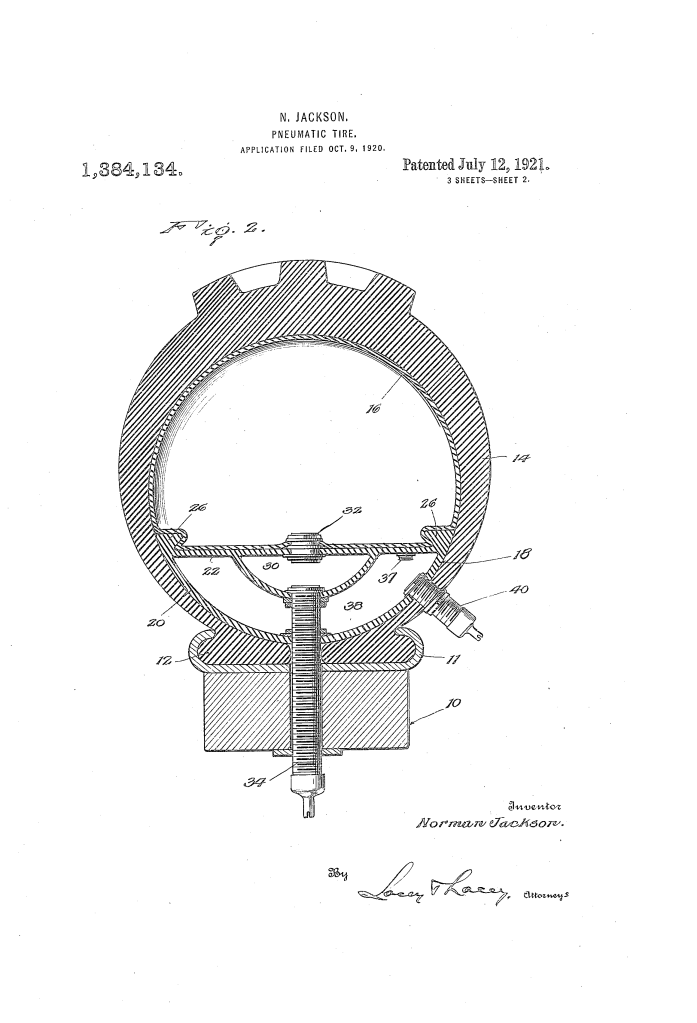

2. The Main and Emergency Supply Chambers (30, 38)

- Main Chamber (30): A central supply line that feeds air to all ten main sections simultaneously through one-way valves (32).

- Emergency Chamber (38): A second, larger-capacity chamber that holds highly compressed air reserved for emergencies.

- Independent Valves: These chambers are inflated through separate external valves (34 and 40), allowing the driver to prime the emergency system independently.

3. Automatic Emergency Displacement (34*) (Key Innovation)

The most innovative feature of Jackson’s design is the emergency sections (34)*.

- Compressed State: Normally, the emergency sections are folded or compressed between the ends of the main sections by the pressure of the main tubes.

- Automatic Inflation: If a main section (16) is punctured and loses pressure, it no longer compresses the adjacent emergency section.

- Action: The high-pressure air from the emergency chamber (38) immediately rushes through valves (37) into the emergency section. This causes it to expand and “displace” (take the place of) the failed main section, keeping the tire functional.

4. The Flange and Groove Lock (26, 28)

- Structural Stability: To prevent the independent sections from shifting under the centrifugal force of a moving car, the supply tube has flanges (26) that lock into grooves (28) on the sections.

- Function: This ensures that even when a section is deflating or inflating, the internal components maintain their proper alignment within the casing (14).

Improvements Over Standard Pneumatic Tires

| Feature | Standard 1920s Inner Tubes | Jackson’s Sectional Tire |

| Puncture Response | Immediate total deflation and loss of control. | Only one section fails; others remain at full pressure. |

| Emergency Recovery | Requires immediate stop and manual repair. | Automatic displacement by emergency tubes. |

| Inflation | Single valve; hard to regulate pressure. | Dual-chamber system for simultaneous, uniform inflation. |

| Safety | High risk of rim damage and accidents. | Tire maintains its shape even after multiple punctures. |

Significance to Automotive Engineering

Norman Jackson’s tire influenced the development of multi-chamber safety tires and run-flat technology.

- Compartmentalization: The logic of dividing a pressure vessel into “cells” to limit damage is a fundamental principle used today in everything from submarine hulls to spacecraft fuel tanks.

- Redundant Pneumatics: His use of a secondary, high-pressure “buffer” tank to automatically correct a system failure is a precursor to modern emergency air-brake reservoirs and ballistic parachute deployment.

- Automatic Load Transfer: The way the emergency sections “take the place” of failed components demonstrates an early understanding of dynamic load-path management in mechanical systems.

- Maintenance Reduction: Jackson correctly predicted that his construction would mean “the puncturing of a tire would not necessitate immediate repair,” a philosophy that drives the modern Run-Flat Tire (RFT) industry.