Plasterer’s Hawk (John L. Love, No. 542,419)

The patent by John L. Love of Medford, Massachusetts, describes an improved Plasterer’s Hawk (the flat, square board used by plasterers to hold mortar or plaster). The invention aims to solve several problems with traditional wooden hawks: warping due to moisture, wearing out and protruding fasteners, and inconvenience of transport.

Invention and Mechanism

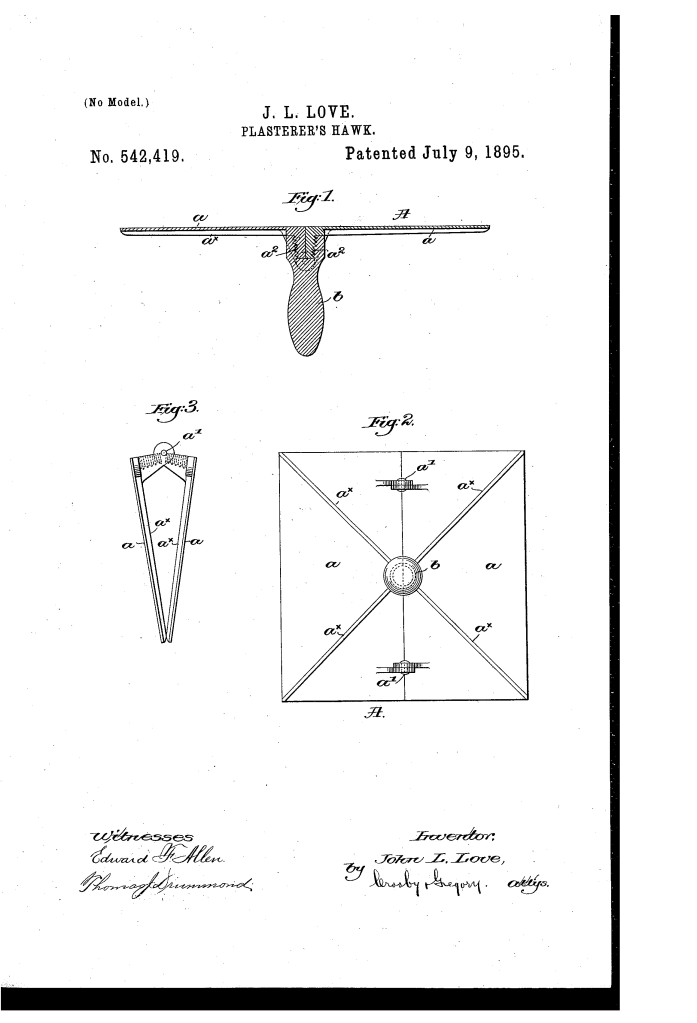

Love’s hawk is a collapsible, metal design that uses its removable handle to lock the working surface together.

- Construction and Material: The holding plate (A) is preferably constructed from aluminum to prevent warping and uneven wear . The plate is divided through its middle to form two like members (

), which are hinged () together.

- Collapsing and Transport: When the handle is removed, the two plate members (

) can be folded about their hinges, making the hawk easily transportable in a plasterer’s bag.

- Locking Mechanism (Removable Handle): Each hinged plate member has a semicylindrical shank member that abuts the other to form a single, threaded shank when the plate is opened.

- Conical Threading: The combined shank is preferably a conically-threaded nipple, and the removable handle (b) has a correspondingly conical threaded socket.

- Function: Screwing the handle (

) onto the conical shank acts to draw the two plate members tightly together, locking them rigidly into their flat working position. The handle is the sole fastener required to hold the hawk together during use.

Historical Significance and the Inventor

- Trade Tool Improvement: The design addressed the core issues that reduced the longevity and functionality of the standard wooden hawk—namely, warping due to moisture and interference from protruding fasteners. By using metal and a fastener-free working surface, the invention improved the quality and consistency of the plasterer’s application.

- Portability: The removable handle and folding plate specifically improved the portability for traveling tradesmen, acknowledging the practical needs of workers who carried their tools between job sites.

- The Inventor (John L. Love): John Love is recognized as an African-American inventor who focused on tools for specific trades, demonstrating ingenuity in simplifying and improving existing equipment for professional workers.

Core Concepts Utilized Today

The concepts behind Love’s invention are integrated into modern equipment that requires portability, durability, and a rigid, quick-assembly structure.

- Collapsible Work Surfaces: The concept of a working surface divided and hinged to be folded flat for transport is the basis for many modern folding camp tables, portable workbenches, and specialty construction tools that collapse for compact storage.

- Compressive Locking Mechanisms: The principle of using a removable component (the handle) to actively compress and lock hinged pieces into a single, rigid unit is applied in:

- Quick-Assembly Poles: Systems in telescoping equipment and portable tripods where a single action locks multiple components into a fixed position.

- Tapered Locking Systems: The use of a conical (tapered) fit or compression to draw modular components together for a rigid, zero-tolerance connection is standard in high-precision applications like industrial tool holders and specialized optical mounts.

- Durable Materials: The early use of aluminum to resist warping and maximize the strength-to-weight ratio is standard in high-quality professional finishing tools today, including modern aluminum hawks, floats, and trowels.