Planter (George W. Murray, No. 520,887)

The patent by George W. Murray of Sumter, South Carolina, describes an improved Planter designed for continuously dropping corn, peas, and other seeds at predetermined distances, followed immediately by mechanisms for covering the seed and shaping/blocking the drill.

Invention and Mechanism

The planter is a wheeled, framed machine that integrates the planting, covering, and consolidation functions in a single pass.

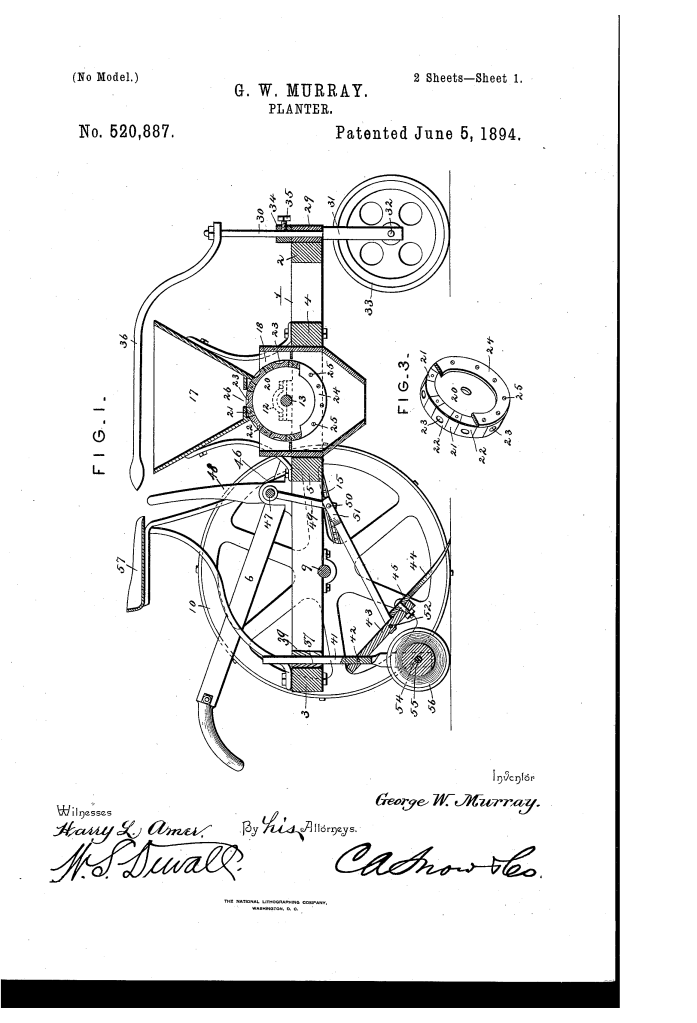

1. Planting Mechanism (Seed Dropper)

- Hopper (17): A container for the seeds, mounted above the frame.

- Shaft Drive: A transverse shaft (13) is driven by a sprocket-chain (15) connected to the main axle (9) and ground-wheels (10).

- Seed-Wheel (20): A cast-metal wheel revolving with the shaft (13), located directly beneath the hopper’s slotted discharge end (26).

- Adjustable Seed Cups: The wheel has integrally formed dovetailed blocks (21) that create recesses. Reversely beveled seed-cups (22) are removably inserted into these recesses and held by a clamping-ring (24) and screws (25).

- Function: As the wheel turns, each cup is successively exposed to the seed in the hopper, receives a quota of seed, and then drops it through a discharge spout (19) into the ground.

- Spacing Control: To plant seeds farther apart, some of the seed cups (22) can be removed and replaced with blank-cups (27), allowing the farmer to adjust the planting density.

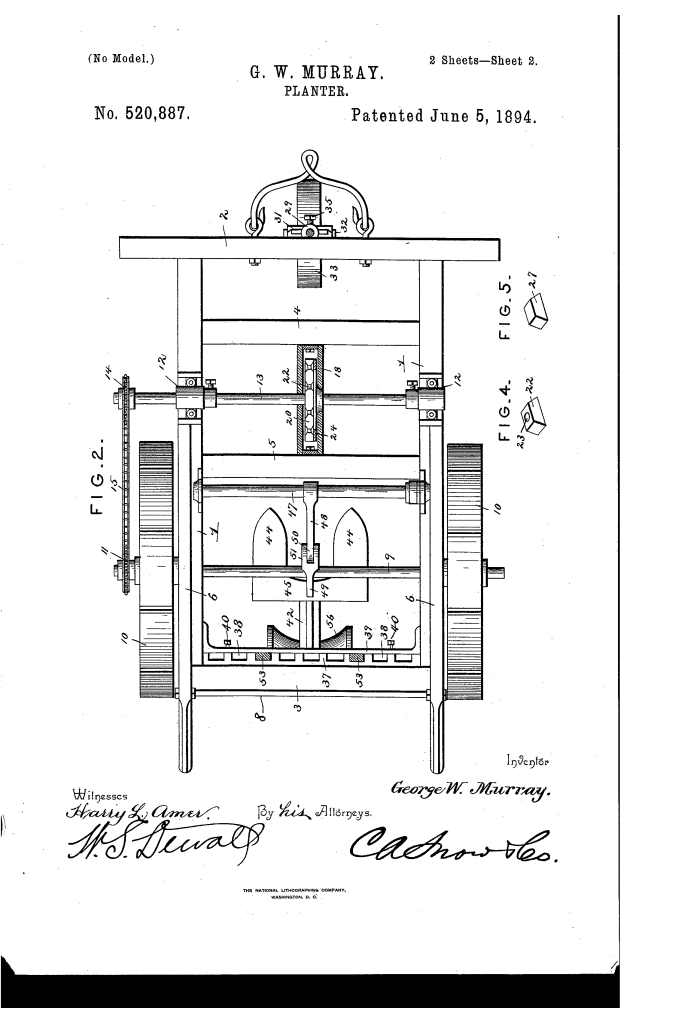

2. Covering Mechanism

- Twin Shovel (44): A special twin-pattern shovel consisting of opposite blades connected by an intermediate web (45).

- Function: This shovel is positioned to straddle the path traversed by the hopper. The blades cast the loose dirt over the seed that has just been dropped, thus forming the initial drill.

- Adjustment: This shovel-carrying standard (43) can be raised or lowered out of the ground by the operator using a lever (48) connected to a rock-shaft (47) via a link (51).

3. Shaping/Blocking Mechanism

- Vertical Standards (53): Standards inserted into recesses (38) on a rear plate (37), maintained by a clamping bar (39).

- Blocking-Wheel (56): A roller mounted on an axle (55) at the rear of the machine.

- Function: The wheel has a concaved periphery that follows the twin-shovel (44). It serves to shape or block the drill into a ridge, consolidating the soil over the covered seeds in a manner that will be obvious to a farmer.

4. Steering and Control

- Caster-Wheel (33): A front caster-wheel with a shank (30) swiveled in a bearing (29) allows for steering.

- Handle (36): Projects rearward over the machine, enabling the operator to control the movement, whether walking behind or riding on the seat (57).

Historical Significance and the Inventor

This 1894 patent is another key innovation by George W. Murray, the African-American inventor and politician from South Carolina. It furthers his goal of providing affordable, efficient, and precise agricultural tools for Southern farmers.

- Precision and Efficiency: The invention’s main significance is its focus on mechanical precision in planting. The adjustable seed-cup system for controlling seed spacing and the immediate, sequential covering and blocking operations ensured uniformity that manual planting could never achieve. This direct link between mechanization and planting efficiency was crucial for maximizing yields and profitability for farmers of limited means.

- Modular Design: The use of interchangeable seed cups (22) and blank cups (27) to change the planting density made the machine highly valuable. Instead of needing different machines for different crops or spacing requirements, the farmer only needed to swap a few cups, providing flexibility essential for diverse small farms.

- Soil Management: The two-stage soil treatment (covering/hilling followed by consolidation/shaping) demonstrates an awareness of the need to protect newly planted seeds, prevent erosion, and maximize germination—all critical aspects of sound agricultural practice.

Relation to Current Items

Murray’s planter is a functional antecedent for modern row-crop planting and conservation tillage technology:

- Interchangeable Seed Plates/Cups: The system of using removable cups and blanks to control spacing is the direct ancestor of modern precision planter meters , which use interchangeable plates or pneumatic singulators to meter seeds precisely based on the required population density for corn, cotton, or soybeans.

- Integrated Planting Units: The sequential operation—furrow opening (implied, though not shown in the patent’s shovel) → seed drop → covering (twin shovel) → consolidation (concaved roller)—is the exact operational order of every modern row-unit on a tractor-pulled planter .

- V-Shaped Closing Wheels: The “blocking-wheel” (56) with its concaved periphery performs the same function as modern V-shaped closing wheels or press wheels on planters, which are designed to firm the soil directly over the seed trench to ensure good seed-to-soil contact and promote uniform germination.