The patent by Clatonia Joaquin Dorticus of Newton, New Jersey, describes an improved Photographic Print Washer (Patent No. 537,968, 1895). The invention’s primary objective is to efficiently and uniformly wash photographic prints and negatives to eliminate sodium hyposulfite (hypo) and other chemicals, which, if left, would ruin the photos’ permanency or luster. The design focuses on solving several problems of existing washers, including prints sticking, tearing, or being unnecessarily over-washed.

Invention and Mechanism

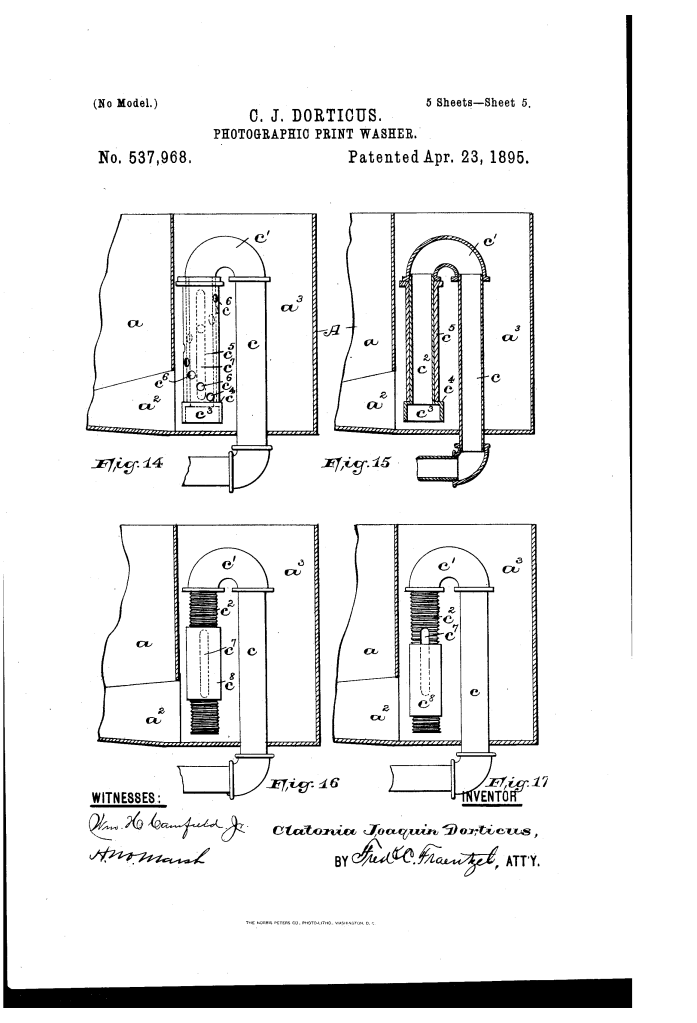

The washer is a highly automated system involving a specialized tank, a circulating current, and mechanisms for flow regulation, automatic shut-off, and wash cycle tracking.

1. Tank Design and Circulation

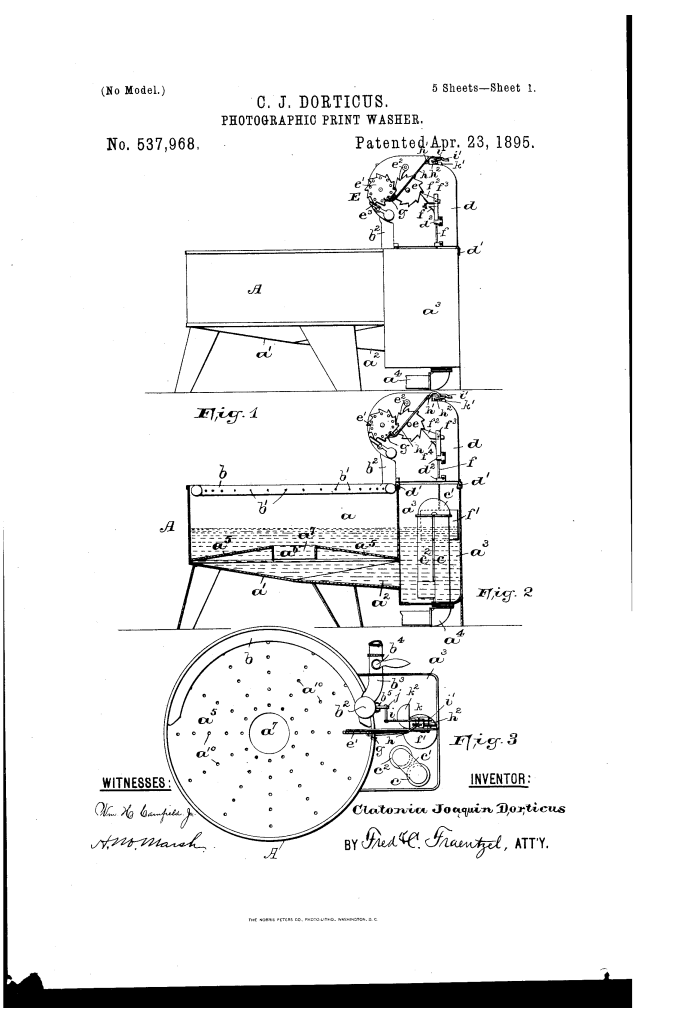

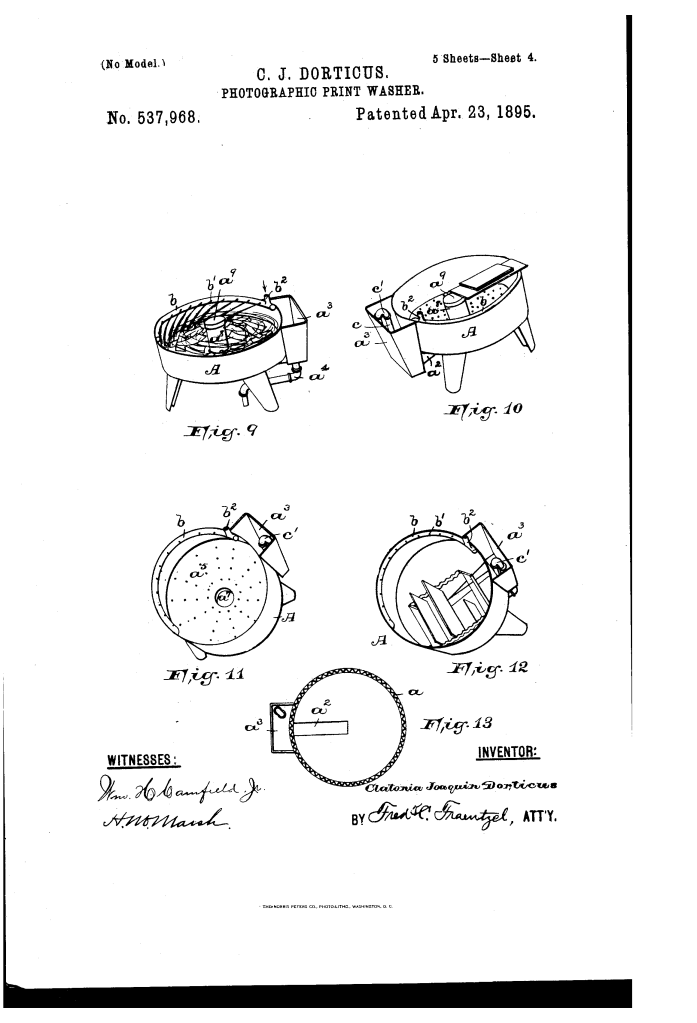

- Tank (A): Circular or otherwise shaped, provided with a sloping (conical) bottom (c) and corrugated or uneven sides (a).

- Function: The uneven sides prevent prints from sticking to the sides (which ruins them), and the water supply pipe (b) introduces water at an angle to produce a circular flow or current, ensuring the pictures are in continuous motion.

- Removable False Bottom (a′): This cone-shaped piece, with upwardly flaring sides and perforations (a5), is placed over the main bottom.

- Function: It prevents prints from touching the very bottom. By removing it, the tank can be used to wash negatives, making it a combined print and negative washer. Chemicals (hypo salts) being heavier than water, settle beneath the false bottom, preventing film damage.

2. Siphon, Outflow, and Flow Control

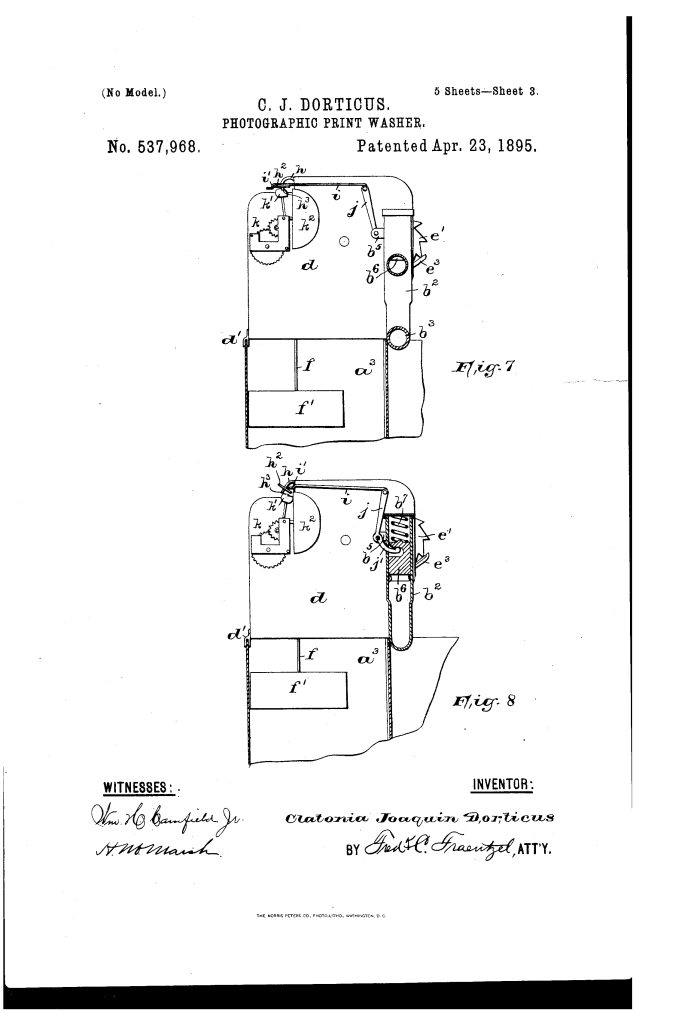

- Well (a4): A partitioned well connected to the main tank by a duct (a3).

- Adjustable Siphon (c,c3): A siphon draws water from the well’s bottom (a5). The siphon’s exit is controlled by an adjustable mechanism (a spirally perforated pipe or a slotted pipe with a screw-threaded sleeve).

- Function: The siphon’s draw-off capacity is intentionally in excess of the inflow, ensuring a constant, fresh water exchange. The adjustment allows the operator to control the final water level remaining in the tank after siphoning, preventing prints from drying and curling.

3. Automatic Shut-Off and Registering System

This is the most complex and novel feature, ensuring prints are not over-washed.

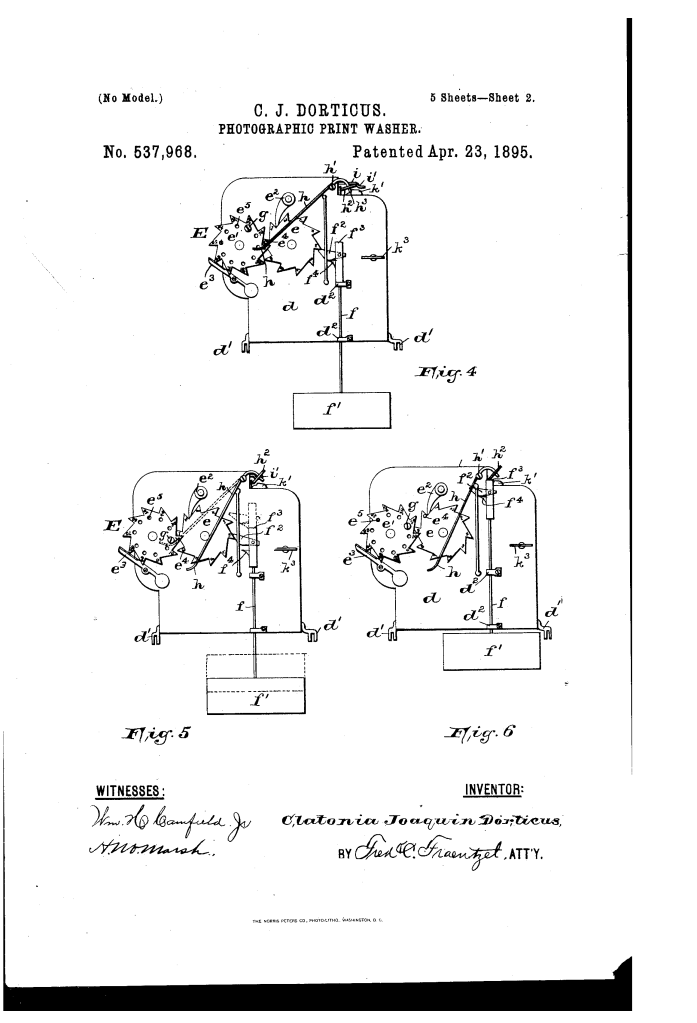

- Float (f′): A float is located in the well (a4), attached to a vertical rod (f).

- Automatic Register (E): Consists of two ratchet disks (e,e′) with numbered teeth, designed to record up to 100 wash cycles. A pawl (f2) on the float rod advances the register.

- Function: As the tank fills and empties, the float operates the register, which records the number of changes of water.

- Automatic Water Shut-Off:

- The ratchet disk (e′) has a series of screw-threaded holes (e2). A stop pin (g) is screwed into the hole corresponding to the desired number of washes (e.g., 20).

- A system of pivoted levers (h,i,j) is connected to the water supply valve (b2).

- Function: When the register reaches the count set by the pin (g), the pin engages the lever system, causing it to release a holding mechanism, and a spring (b3) automatically shuts off the water supply.

- Alarm (k): An alarm mechanism is connected to the lever system. When the water supply is shut off, the hammer (k′) is released, and the alarm rings, notifying the operator the washing is complete.

- Overflow Safety: The float rod (f) has an upper end (f4) that will strike the lever system if the water rises too high (due to siphon failure), automatically shutting off the water and activating the alarm.

Historical Significance and the Inventor

Clatonia Joaquin Dorticus’s 1895 patent represents a crucial step in the industrial and amateur photographic darkroom, addressing the need for consistency and efficiency.

- Hypo Elimination: Hypo (sodium thiosulfate) salts, used as a fixer, must be completely eliminated from prints and negatives; otherwise, they degrade the image over time. Historically, this meant long, manual washing and frequent water changes. Dorticus’s washer provided an automated, reliable, and timed process to guarantee chemical removal without the risk of over-washing (which dulls albumen prints).

- Quality Control through Automation: The most significant innovation is the automatic register and shut-off. This turned a tedious, imprecise manual task into a measured, high-quality, set-and-forget operation, greatly enhancing darkroom efficiency.

- The Inventor (Clatonia Joaquin Dorticus): Dorticus, an African-American inventor, contributed sophisticated mechanical and fluid-dynamic solutions to the niche but growing photography industry, demonstrating high-level engineering in a civilian, consumer-focused application.

Relation to Current Items

Dorticus’s washer is the conceptual and functional ancestor of various modern fluid and washing technologies:

- Automated Laboratory Washers: The system of a washing vessel with a timed, measured water change and an automatic shut-off is the core concept behind modern laboratory glassware washers and industrial parts washing machines , which use cycle counters and flow meters to ensure purity and efficiency.

- Convection in Processing Tanks: The design of the tank with angled water input to create a circular current for mixing and agitation is a widely used principle in chemical processing, pharmaceutical preparation, and beverage manufacturing to ensure homogenous mixing in large tanks.

- Sump and Overflow Protection: The well/siphon system and the float-actuated overflow shut-off are simple, robust mechanical safety features used today in various appliances like washing machines, dishwashers, and industrial fluid sumps to prevent flooding.

- Removable Partitions/False Bottoms: The use of a removable false bottom to convert the tank for different uses (prints vs. negatives) is a simple modularity principle common in all forms of specialized equipment.