The patent by John Lee Love of Fall River, Massachusetts, describes an improved Pencil-Sharpener (Patent No. 594,114, 1897). The primary objective is to provide a simple, effective, and ornamental device that is also adaptable for use as a paper-weight or desk ornament.

Inventor Background: John L. Love

John L. Love was an African-American inventor who contributed several notable patents to domestic and trade tools.

- Focus on Trade and Utility: Love is known for his invention of the Plasterer’s Hawk (Patent No. 542,419, 1895), a collapsible, non-warping metal tool for tradesmen.

- The Pencil Sharpener Context: His pencil sharpener design, like his hawk, focuses on improving a common tool’s efficiency (by simplifying the sharpening motion) while simultaneously enhancing its utility (as a paperweight) and aesthetics (as a desk ornament). His work consistently demonstrates practical ingenuity aimed at both professional trades and household convenience.

Invention and Mechanism

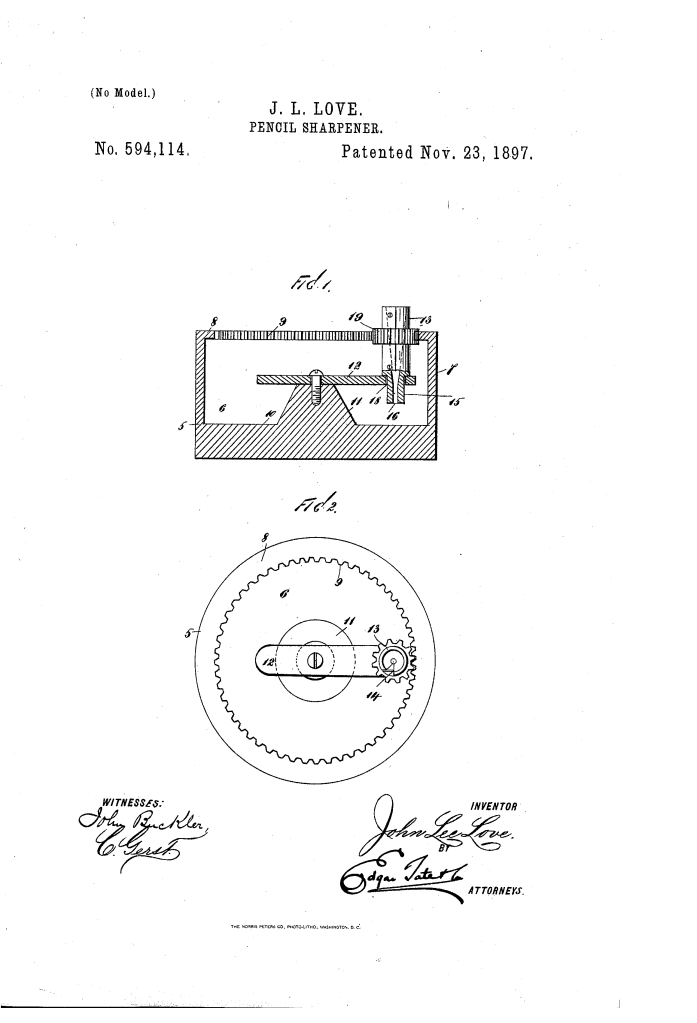

The pencil sharpener is a stationary desktop device that uses a geared, orbiting motion to rapidly spin the cutter around the pencil point.

1. Frame and Orbiting Mechanism

- Casing (5): A block or casing (preferably circular) that serves as the base and paperweight. It contains a circular chamber (6) for collecting shavings.

- Geared Rim (8): The inclosing wall (7) of the chamber (6) has an inwardly-directed flange or rim (8) at its top, provided with fixed gear-teeth (9).

- Pivoted Arm (12): An arm or plate pivoted centrally on a raised portion (11) in the bottom of the chamber. This arm orbits freely around the center of the casing.

2. Sharpener Head and Gear Drive (Key Innovation)

- Pencil-Sharpener (13): A cylindrical cutter unit (of usual conical construction with a cutting-blade 14) that is revolubly mounted in one end of the orbiting arm (12).

- Pinion (19): The body of the sharpener (13) is provided with a pinion or gear-wheel (19).

- Operation:

- The user inserts the pencil point into the sharpener (13) and applies slight pressure.

- The sharpener (13) is carried around with the orbiting arm (12) by the user’s hand.

- As the arm (12) orbits, the sharpener’s pinion (19) engages the fixed gear-teeth (9) on the rim. This engagement causes the pencil-sharpener itself to be rapidly revolved as it orbits.

- Result: The combination of the orbiting motion and the rapid rotation of the sharpener quickly and efficiently sharpens the pencil.

3. Shavings Collection

- Extension (15) and Bore (16): The sharpener has a reduced tubular extension (15) with a small central bore (16) that passes through the arm (12).

- Function: This bore allows the finely-divided pencil material (shavings/graphite dust) to drop cleanly downward into the chamber (6) in the base, keeping the desktop tidy.

Concepts Influenced by This Invention

Love’s sharpener influenced the design of subsequent mechanical tools by pioneering the use of a fixed-ring gear drive for portable, hand-actuated motion amplification.

- Fixed Ring-Gear Actuation: The concept of mounting a rotating tool (the cutter) on a portable carriage (arm 12) and using a fixed ring of gear teeth (9) to generate high-speed internal rotation influenced the design of:

- Hand-Cranked Tools: Mechanisms in various hand-operated grinders and drills that achieve rotational speed multiplication from simple translational input.

- Precision Jigs: Industrial or scientific jigs that use a base structure to house a fixed gear for manually driving a portable, orbiting tool head.

- Integrated Utility (Multi-Functionality): The explicit design objective to make the device suitable as an ornamental paper-weight influenced the engineering trend of integrating tools with aesthetic or passive utility functions (e.g., pen holders, desktop organizers).

- Planetary/Epicyclic Motion (Conceptual): Although driven manually, the sharpener’s motion is conceptually similar to a planetary or epicyclic gear system, where one component (the pinion 19) is rotated around a central axis while engaging a fixed external gear (9). This mechanical arrangement is used in various modern drive systems requiring high torque or speed reduction.