Paper-Rewind Mechanism for Adding-Machines (Shelby J. Davidson, No. 884,721)

The patent by Shelby J. Davidson of Lexington, Kentucky, describes a new and useful Improvement in Paper-Rewind Mechanism for Adding-Machines (Patent No. 884,721, 1908). The primary object is to provide an attachment that will care for the printed paper strip, reeling it up step-by-step automatically, eliminating the need for manual winding and preventing the strip from being mutilated. A secondary object is to provide an alarm or signal mechanism to warn the operator when the paper strip runs out or tears.

Inventor Background: Shelby J. Davidson

Shelby J. Davidson (c. 1871–1930s) was a notable African-American inventor and government professional whose career focused on efficiency in the fields of accounting and office management during the early 20th century.

- Career and Context: Davidson was a resident of Lexington, Kentucky, when he filed his patent. However, he is historically recognized for his career in Washington, D.C., where he worked as a bookkeeper for the U.S. House of Representatives. This professional duty required him to use and manage early office machinery, providing him direct insight into the logistical bottlenecks (like manually managing printed paper strips) that his invention sought to solve.

- Focus on Office Automation: His 1908 invention for an adding machine rewind mechanism was a direct response to a real-world need in the fast-paced governmental office environment. His solution—an automatic, synchronized rewind and an alarm for paper failure—improved the workflow, tidiness, and reliability of using these essential financial machines.

Davidson’s background as a professional bookkeeper demonstrates his commitment to applying his mechanical ingenuity to solve practical problems he encountered daily in a demanding commercial and governmental setting..

Invention and Mechanism (Simplified)

The device is a spring-driven spool that automatically takes up the paper slack, integrated with a gravity-powered alarm system.

1. Automatic Rewind System

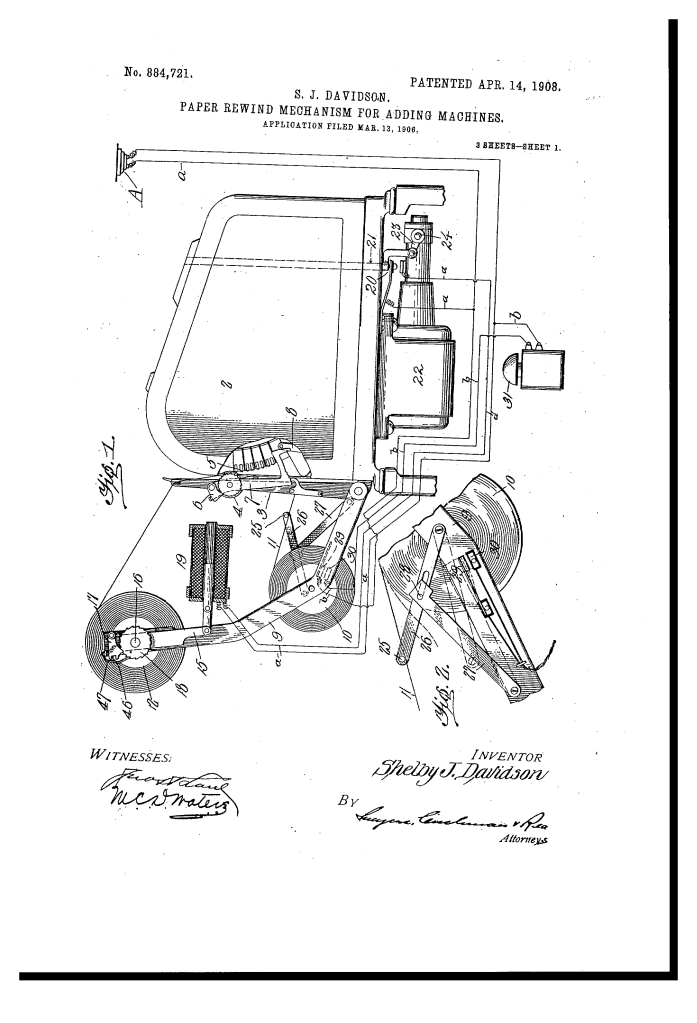

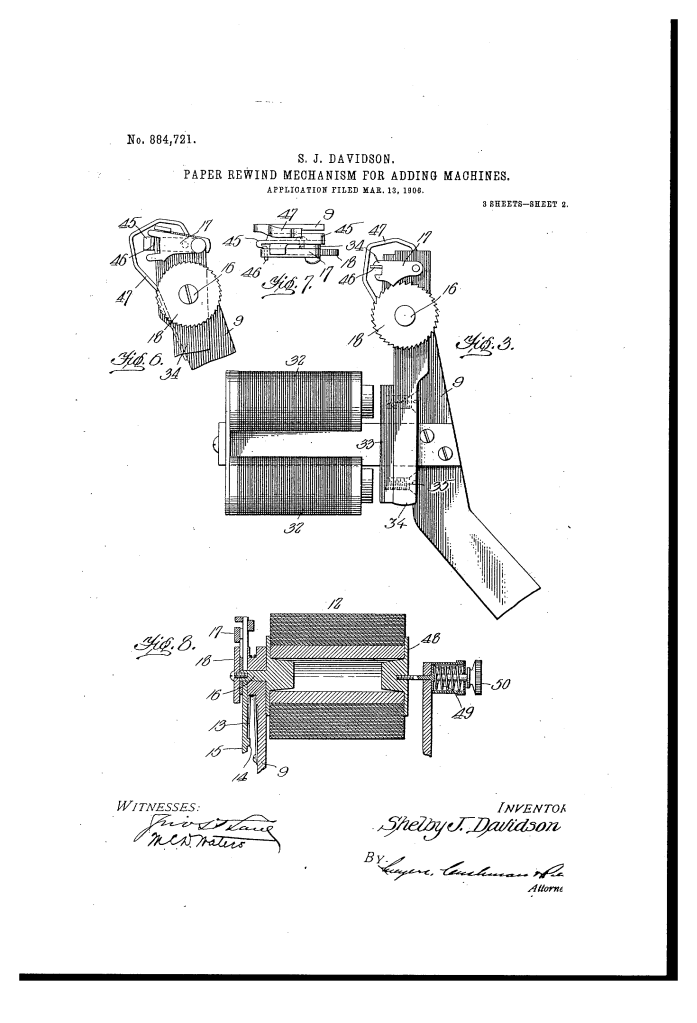

- Supply and Rewind Rolls (10, 12): The machine is fitted with a supply roll (10) and a rewind roll (12) mounted on an auxiliary frame (9).

- Spring Drive (13): The rewind roll (12) is powered by an internal actuating spring (13) that constantly tries to rotate the roll and take up the slack.

- Pawl and Ratchet: A pawl (17) is mounted on a swinging arm (15) and engages a ratchet disk (18) on the rewind roll shaft.

- Actuation (Key Innovation): The swinging arm (15) is linked to a mechanism (solenoid 19 in electric machines, or thrust rod 36 in mechanical machines) that is triggered by the adding machine’s printing cycle.

- Function: As the machine prints and spaces (pulling the paper forward), the trigger mechanism momentarily retracts the pawl (17), winding the internal spring (13) under stress. When the printing cycle finishes, the pawl re-engages, and the stored spring energy rotates the rewind roll (12) just enough to take up the slack created by the printing operation, keeping the strip taut.

2. Alarm Mechanism (Paper-Out/Tear Signal)

- Feeler (25): A small feeler arm (26) with a roller (25) normally rests upon the upper surface of the paper strip (11) between the supply and rewind rolls.

- Signal Arm (27): A hammer lever (27) is pivotally connected to the feeler arm. It is normally held up by the presence of the paper strip.

- Operation: If the paper strip runs out or tears, the feeler arm (26) drops. The hammer lever (27) falls, striking a spring contact arm (29) and closing an electric circuit.

- Result: An audible signal (31) is given, instantly advising the operator of the paper failure.

3. Convenience Features

- Reversal: The rewind roll can be easily removed and reversed, allowing the strip to be used again.

- Automatic Pawl Reset: The pawl (17) can be manually disengaged for consulting the strip, and is designed to automatically return to engaging position when the machine starts operating again.

Concepts Influenced by This Invention

Davidson’s mechanism influenced subsequent office automation and material handling by pioneering intermittent, spring-driven take-up synchronized with cyclic machine operations.

- Synchronous Take-Up/Rewind: The core concept of using a spring-driven rewind roll (12) that is intermittently “cocked” (pawl 17) by the action of the main machine cycle influenced the design of:

- Receipt Printers and POS Systems: Mechanisms for automatically advancing and trimming paper in retail and commercial printers.

- Film and Tape Reels: Automatic take-up mechanisms in vintage cameras, tape recorders, and industrial winding machines.

- Floating Material Sensor (Feeler Arm): The use of a floating, gravity-impelled feeler arm (26) resting directly on the material strip to detect failure influenced the design of material handling and quality control systems:

- Paper-Out/Break Sensors: Used in printers, copiers, and packaging machines to detect material failure and trigger immediate shutdown or alarm.

- Conversion between Drive Types: The design’s successful adaptation for both electric (solenoid 19) and mechanical (thrust rod 36) drive mechanisms influenced the engineering of standardized components adaptable across diverse industrial power sources.

- Office Automation: The invention contributed to the large trend in the early 20th century toward automating logistics in the office environment, maximizing the efficiency of clerks and bookkeepers.