Process of Producing Paints and Stains (George Washington Carver, No. 1,632,365)

The patent by George Washington Carver of Tuskegee, Alabama, describes a specialized Process of Producing Paints and Stains (Patent No. 1,632,365, 1927). This invention is a chemical method for extracting high-quality pigments, wood fillers, and stains from natural clays. Carver’s primary objective was to utilize the abundant, iron-rich clays of the Southern United States to create a wide palette of affordable, durable, and beautiful colors. His innovation relies on a meticulous acid-digestion process that reduces clay to a gelatinous state, allowing it to strike deep into wood fibers or be mixed with oils as a permanent pigment.

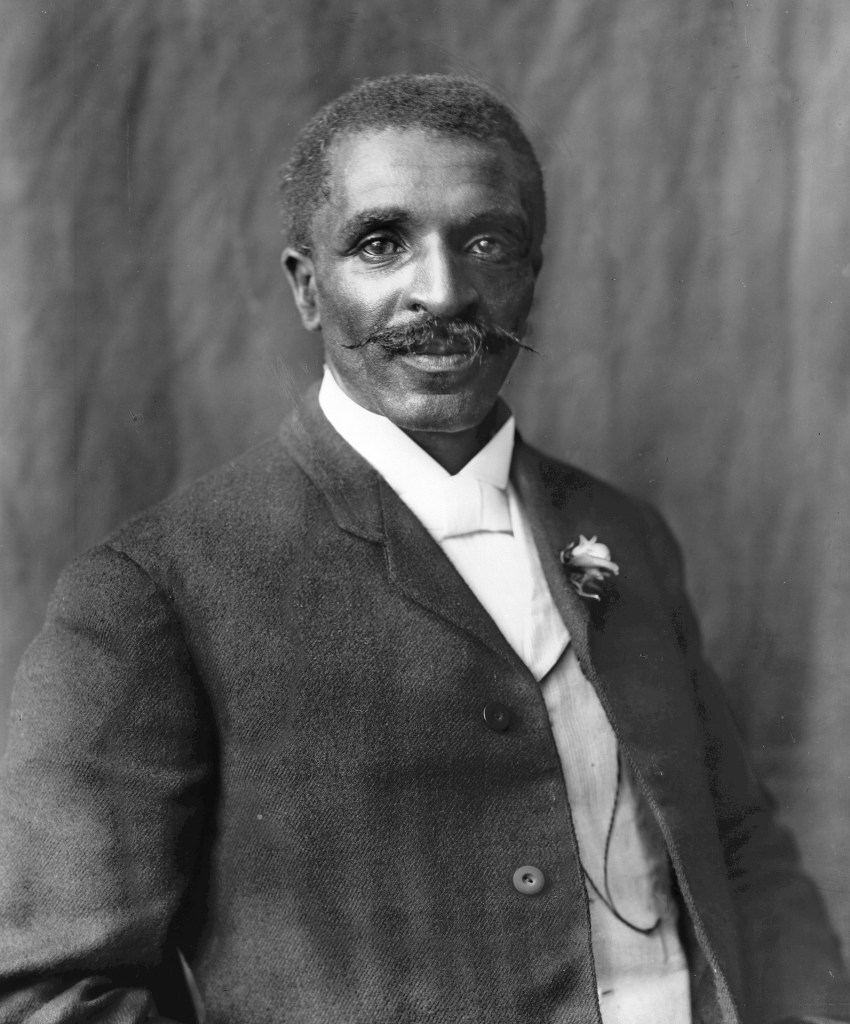

Inventor Background: George Washington Carver

George Washington Carver (c. 1864–1943) was a world-renowned African American scientist, botanist, and inventor. While widely known for his work with peanuts and sweet potatoes, his 1927 patent represents his mastery of Chemurgy—the branch of applied chemistry that turns agricultural and natural raw materials into industrial products. Working out of the Tuskegee Institute, Carver sought to empower poor Southern farmers by showing them how to find value in the very soil beneath their feet. This patent is a testament to his “waste-not” philosophy and his deep understanding of mineralogy and oxidation.

Key Chemical Systems & Process Steps

Carver’s process transforms raw, ferruginous (iron-bearing) clay into a refined chemical base through a series of reactions.

1. Refining and Acid Treatment

- The Base: Clay with a high percentage of iron (ideally ~5.6% peroxide of iron and 16.7% aluminum) is finely divided.

- Digestion: 25 lbs of clay is mixed with 25 lbs each of commercial sulphuric acid and hydrochloric acid, plus 3 lbs of clean scrap iron (turnings).

- Boiling: The mass is boiled slowly in an acid-proof porcelain vessel until the iron dissolves and the mass becomes uniform in color.

- Function: This “acid-bath” breaks down the mineral structure of the clay, reducing it to a gelatinous condition that is ideal for absorption into porous materials like wood.

2. Decantation and Separation

- Dilution: Water (alkali-free) is added to double the volume.

- Settling: The mixture sits for five minutes to allow coarse, insoluble particles to sink.

- Decantation: The liquid containing the suspended pigment is poured off, and the waste material is discarded.

- Function: This ensures the resulting stain or paint is “exceedingly smooth” and free of grit.

3. Color Synthesis (The Blue Process) (Key Innovation)

To produce a rich “Prussian” style blue, Carver introduced a specific oxidation sequence:

- The Reagent: 25 lbs of potassium ferricyanide solution is added to the base.

- Oxidation: 12 lbs of concentrated nitric acid is added.

- The Slow Process: The mixture is stirred every two weeks for three months.

- Action: This allows for a slow, deep oxidation, resulting in a finer blue color than “quick” processes using live steam.

4. Wood Filling and Staining

- Integrated Application: When the clay is treated with acid (omitting the iron and ferricyanide), it acts as a combined filler and stain.

- Function: It “strikes into” the wood fiber, hardening as it dries to create a smooth surface that requires no additional finishing. Carver noted that wood treated this way actually becomes more beautiful over time.

Pigment Variations & Colors

Carver demonstrated that by varying the chemical additives, a full spectrum of colors could be achieved from the same clay base:

| Resultant Color | Chemical Additive | Natural Variation |

| Prussian Blue | Potassium Ferricyanide + Nitric Acid | N/A |

| Green | Potassium Ferricyanide + Yellow Ochre | N/A |

| Mahogany Brown | Potassium Sulphocyanide | Results from oxidation on the wood. |

| Natural Earth Tones | None (Acid treatment only) | Dependent on the choice of colored clay. |

| High Sheen | N/A | Achieved by using micaceous clay. |

Significance to Chemistry and Industry

George Washington Carver’s process influenced the development of sustainable manufacturing and industrial mineralogy.

- Utilization of Natural Resources: Carver pioneered the idea of “localized industry,” showing that high-end consumer goods (paints) could be produced from low-cost, local raw materials (clays and scrap iron).

- Advanced Oxidation Techniques: His “slow process” for blue pigment showed a sophisticated understanding of chemical kinetics, prioritizing quality and molecular stability over speed.

- Chemurgy in Practice: This patent is a prime example of turning a natural mineral “waste” into a value-added product, a cornerstone of modern green chemistry.

- Wood Science: His combined filler-and-stain method anticipated modern impregnated wood treatments, where chemicals are used to modify the physical properties of the wood grain itself for better durability.