📦 Package-Tie (John S. Allen, No. 1,093,096)

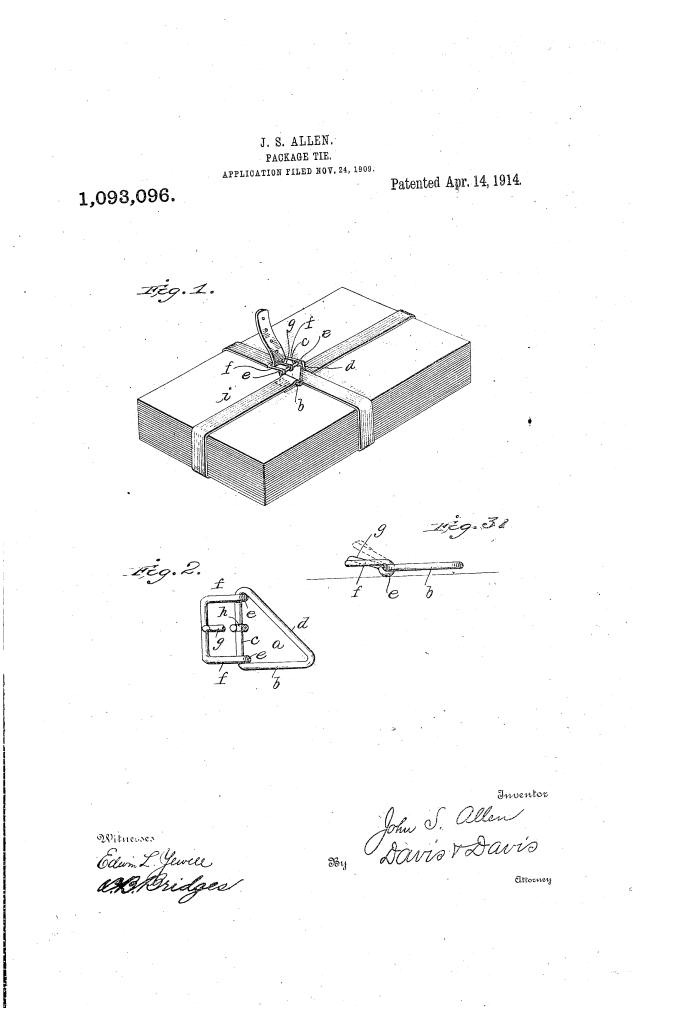

The patent by John S. Allen of Columbus, Georgia, describes an improved Package-Tie (Patent No. 1,093,096, 1914). This invention is a specialized fastening device designed to quickly and securely tie up bundles of papers or letters. It consists of a unique triangular wire frame coupled with a hinged buckle, allowing for a two-way (cross-wise) wrap of a strap that stays perfectly aligned and taut without distorting the metal frame or tearing the strap.

Inventor Background: John S. Allen

John S. Allen was an African American inventor and businessman based in Columbus, Georgia. His patent, filed in 1909, addresses a common clerical and postal need of the early 20th century: the rapid organization of loose documents. Before the widespread use of rubber bands or plastic binders, “package-ties” were essential tools in government offices, law firms, and post offices. Allen’s design is a sophisticated example of mechanical geometry, using a right-triangle frame to solve the problem of strap-slip and frame distortion that plagued earlier, more primitive ties.

Key Mechanical Components & Functions

The device is composed of a rigid wire loop, a hinged buckle, and a durable strap.

1. The Right-Angle Triangle Frame (a)

The foundation of the device is a wire frame ($a$) shaped like a right triangle, consisting of three specific bars:

- Bar (b): The side where the strap (i) is permanently attached.

- Bar (c): Positioned at a right angle to bar ($b$). This bar serves as the mounting axis for the buckle.

- Hypotenuse Bar (d): Connecting the two, lying at a 45-degree angle.

- Function: When the strap is wrapped around a package in one direction and then turned at a right angle for the second wrap, it is pulled against this diagonal bar ($d$). This ensures the pull is directed straight away from the buckle, preventing the frame from twisting or “tilting” during use.

2. The Hinged U-Shaped Buckle (f)

- Pivot Attachment (e): A U-shaped buckle frame ($f$) is pivotally attached to bar ($c$) via eyes ($e$).

- Tongue (g) and Notch (h): A buckle tongue ($g$) is also mounted on bar ($c$). Its eye portion sits in a groove or notch (h) in the center of the bar.

- Function: This prevents the tongue from sliding side-to-side, ensuring it always aligns perfectly with the eyelets in the strap. Because the buckle is hinged, it can swing independently of the main frame, making it much easier to thread and tighten the strap even when the package is bulky.

3. The Strap (i)

- Eyeleted Holes: The free end of the strap is provided with metal eyelets.

- Function: These allow the buckle tongue to lock into the strap securely without the risk of the material tearing or cutting under high tension.

Improvement Over Existing Technology

| Feature | Standard Package Ties | Allen’s Package Tie |

| Durability | Frames often distorted under the diagonal pull of the strap. | Triangular frame with a 45° hypotenuse distributes strain equally. |

| Ease of Use | Fixed buckles were difficult to thread on tight bundles. | Hinged buckle swings freely to facilitate quick threading. |

| Strap Alignment | Straps frequently slipped along the bars of the loop. | Integrated notches and eyes prevent lateral sliding of the buckle. |

| Versatility | Usually limited to one-way wrapping. | Designed specifically for two-way (cross) wrapping for maximum security. |

Significance to Mechanical Design

John S. Allen’s package-tie is an excellent study in applied geometry. By utilizing a right-angled frame, he accounted for the vector forces applied when a strap changes direction by 90 degrees.

- Vector Distribution: The 45-degree bar ($d$) acts as a mechanical guide that translates a perpendicular pull into a centered force.

- Hinged Integration: By utilizing one of the frame bars ($c$) as part of the buckle mechanism itself, Allen practiced part consolidation, reducing the weight and cost of the device while increasing its overall structural integrity.