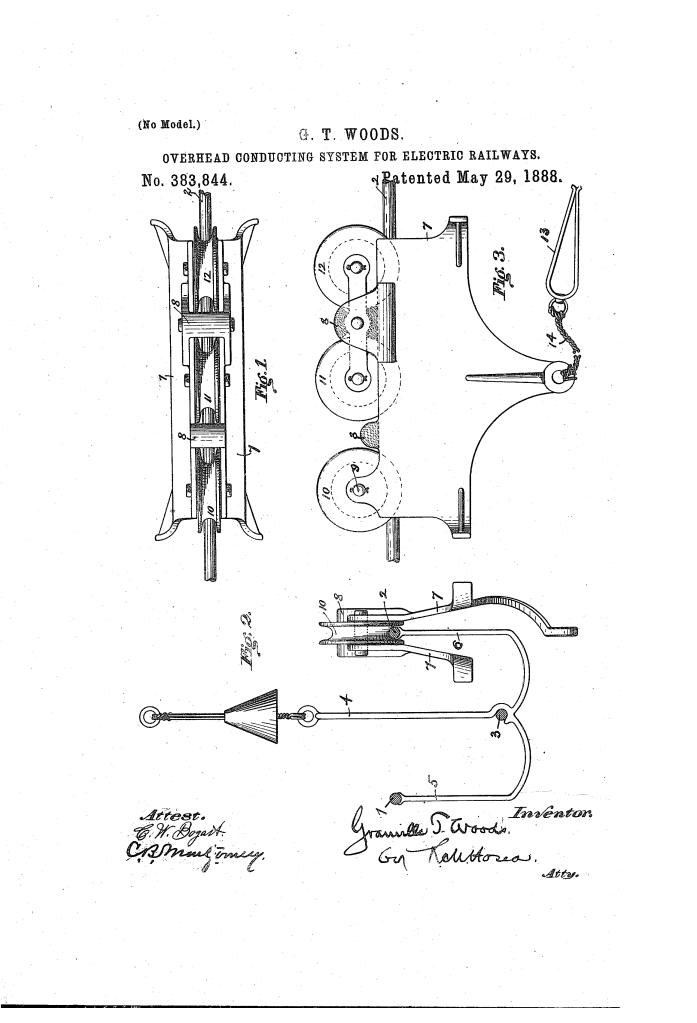

Overhead Conducting System for Electric Railways (Granville T. Woods, No. 383,844)

The patent by Granville T. Woods of Cincinnati, Ohio, describes an Overhead Conducting System for Electric Railways (Patent No. 383,844, 1888). This invention is a specialized power-delivery system designed to provide a constant and reliable flow of electricity to moving railway cars. Woods’s primary innovation was the use of a three-wire conducting path and a pivoted contact carriage (trolley) that could navigate inequalities in the wire alignment without losing electrical contact. This design significantly reduced electrical resistance and provided a fail-safe mechanical connection between the car and the power lines.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910) was an African American inventor often referred to as “The Black Edison” due to his prolific output of electrical and mechanical patents. His work in the late 1880s was instrumental in transitioning urban transit from horse-drawn carriages to electric streetcars. This 1888 patent addressed one of the most difficult challenges in early electric rail: maintaining a steady connection between a bumping, swaying car and a thin overhead wire. Woods’s expertise in traveling electric contacts and circuit stability helped make mass electric transit a viable reality.

Key Mechanical Components & Functions

The system consists of a unique overhead wire bracket and a multi-wheeled carriage that rides atop the wires.

1. The Three-Wire Conducting Path (1, 2, 3)

- The Central Conductor (3): A copper wire (3) is carried at the very bottom of the insulated hanger (4). This wire carries the main current from the generator.

- The Outer Carrying Wires (1, 2): Two iron wires (1, 2) are supported on upward-projecting metallic arms (5, 6).

- Function: The main current from the copper wire is transmitted through the metallic bracket arms to the outer iron wires. This allows the system to use lighter, less expensive wires while achieving a “largely-increased conducting capacity” and lower resistance.

2. The Pivoted Contact Carriage (7, 10, 11, 12)

- The Frame: A light cast-iron frame consisting of two side pieces (7) flared outward at the ends to prevent snagging.

- Grooved Running-Wheels: The carriage rides on three wheels. The rear two wheels (11, 12) are secured in a pivoted truck.

- Function: The pivoted truck allows the wheels to adjust to any bends or “inequalities in the alignment” of the wires. This ensures the carriage maintains constant electrical contact even if the wires are slightly uneven or the car bounces.

3. The Central Extension and Connection

- Curved Extension: One of the side plates extends downward and curves inward toward the central vertical plane of the carriage.

- Function: This positions the motor connection at the “lowest central point,” providing better balance and stability for the carriage as it is pulled along by the car.

4. The Fail-Safe Spring-Clamp (13, 14)

- The Clamp (13): A U-shaped spring metal clamp connects the car’s cable (14) to the carriage.

- Function: The clamp is strong enough to pull the carriage during normal operation. However, if the carriage accidentally stops or snags, the clamp automatically releases the carriage. This prevents the entire overhead conducting line from being torn down, protecting the expensive infrastructure.

Improvements Over Standard Overhead Systems

| Feature | Standard Single-Wire Systems | Woods’s Three-Wire System |

| Electrical Resistance | High; limited by the gauge of a single wire. | Low; utilizes three wires and metallic brackets to increase capacity. |

| Contact Stability | Prone to sparking or “jumping” off the wire. | Pivoted truck allows wheels to follow wire irregularities. |

| Infrastructure Safety | Snags could pull down miles of wire. | Spring-clamp (13) acts as a mechanical fuse, releasing under stress. |

| Mechanical Alignment | Required perfectly straight wire tension. | Flared side plates and pivoted wheels navigate misalignments. |

Significance to Electrical Engineering

Granville T. Woods’s conducting system influenced the development of modern light rail and overhead power distribution.

- Power Redundancy: The use of multiple wires to distribute current is a foundational principle in high-voltage power transmission, ensuring that a break in one path doesn’t necessarily kill the circuit.

- The “Trolley” Evolution: His work on the traveling carriage provided the mechanical logic for the pantograph and trolley pole systems used by streetcars and subways for over a century.

- Breakaway Safety Logic: The concept of a “mechanical release” to protect infrastructure is a standard safety feature in modern industrial cable management and high-speed rail.

- Conductive Bracketry: By utilizing the hanger arms themselves as conductors, Woods demonstrated an early mastery of integrated component design, where structural parts also serve electrical functions.