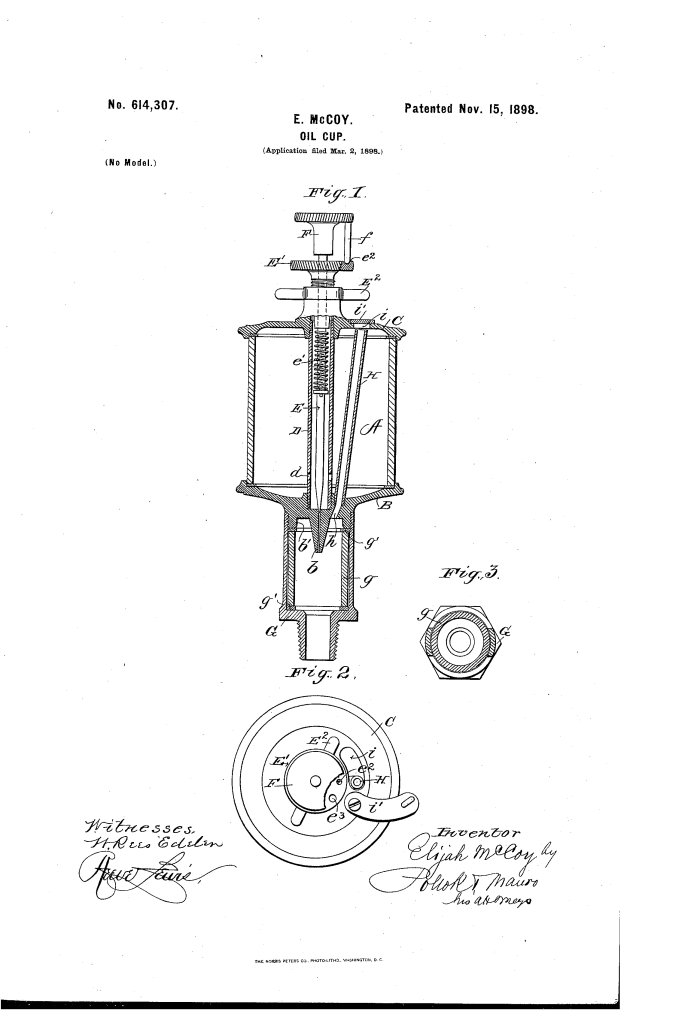

Oil-Cup (Elijah McCoy, No. 614,307)

The patent by Elijah McCoy of Detroit, Michigan, describes a new and useful Improvement in Oil-Cups (Patent No. 614,307, 1898), specifically related to sight-feed oilers for journal-bearings on steam-engines and other machinery. The invention addresses the critical issues of emergency lubrication, oil overflow/waste, and sluggish operation in airtight sight-feed chambers.

Inventor Background: Elijah McCoy

Elijah McCoy (1844–1929) was an exceptionally prolific African-American inventor and engineer known as the original source of the phrase “the real McCoy.” His inventions revolutionized industrial efficiency by providing automated, reliable lubrication for machinery while it was running. This patent is a refinement of his sight-feed oiler designs, incorporating multiple safety and efficiency features demanded by continuous industrial operation.

Invention and Mechanism

The improvement centers on integrating an “emergency feed-tube” that serves three distinct functions: manual oiling, overflow, and venting.

1. The Emergency Feed-Tube (H) (Key Innovation)

- Tube (H) Location: A tube extending upwardly through the oil-reservoir (A) and terminating just below the filling-opening (

) in the top (C).

- Connection: The lower end of the tube (H) communicates with the interior of the sight-feed tube () through a separate passage (

) in the bottom (B) of the cup, distinct from the primary oil-feed nozzle (

).

2. Multi-Functional Utility

The single tube (H) is engineered to solve three separate problems:

- Emergency Lubrication: If the primary feed nozzle (

) clogs, the cover (

) can be swung aside, and a hand-can can be used to feed oil directly into the tube (H). The oil then flows via passage (

) straight to the bearing, ensuring lubrication continues while the clog is fixed.

- Overflow Prevention: If the reservoir (A) is filled too full (a common issue with continuous-supply systems), excess oil passes down through the tube (H).

- Function: Instead of spilling over the exterior of the reservoir (A), the overflow oil is channeled directly to the bearing, preventing waste and exterior mess.

- Air Vent for Sight-Feed (Air-Tight Solution): The sight-feed chamber is designed to be air and dust tight to prevent oil spray (atomization) near rapidly rotating parts. Without venting, the air displaced by oil drops would slow the oil flow.

- Function: The emergency feed-tube (H) provides an independent communication from the sight-feed tube to the atmosphere via passage (

), allowing air to escape easily and ensuring the oil drops form freely without interference.

- Function: The emergency feed-tube (H) provides an independent communication from the sight-feed tube to the atmosphere via passage (

3. Primary Feed System

- Valve Control (E, ): The oil flow from the reservoir is regulated by a central valve stem (E) controlled by a head (F) and various screws and springs, which are designed for precision adjustment (these specific controls are detailed in McCoy’s other patents).

Concepts Influenced by This Invention

McCoy’s Oil-Cup influenced subsequent fluid system design by pioneering multi-purpose, segregated channels for safety, maintenance, and flow integrity.

- Integrated Safety/Maintenance Channel: The most direct influence is the principle of using a dedicated, independent channel (H) within a reservoir for emergency and maintenance access. This concept is used today in fluid systems where an auxiliary port is required for:

- Bypass Oiling/Filling

- Ventilation

- Monitoring

- Air-Tightness with Vented Flow: The design solution for using an air-tight chamber (for cleanliness) while maintaining smooth fluid flow by providing a separate air-communication path (H) influenced the design of modern closed fluid dispensing systems and metering devices that require an integrated vent to prevent vacuum lock or flow restriction.

- Overflow Recovery: The innovative use of the overflow path to recycle the oil directly to the bearing (preventing waste) influenced the design of modern industrial oil management and sump systems that integrate overflow return lines and overflow traps.