The patent by Robert Randolph Reynolds of New York, N.Y., describes a Non-Refillable Bottle (Patent No. 624,092, 1899). The invention consists of a valved stopper adapted to be permanently applied to prevent unauthorized use and misrepresentation (i.e., refilling with counterfeit liquid).

Inventor Background: Robert Randolph Reynolds

Robert Randolph Reynolds was an inventor focused on commercial security solutions, particularly in packaging. His invention addressed the widespread issue of product fraud and counterfeiting in the late 19th-century spirits and medicine industries by engineering a clever, mechanical lock to guarantee the integrity of bottled goods.

Invention and Mechanism

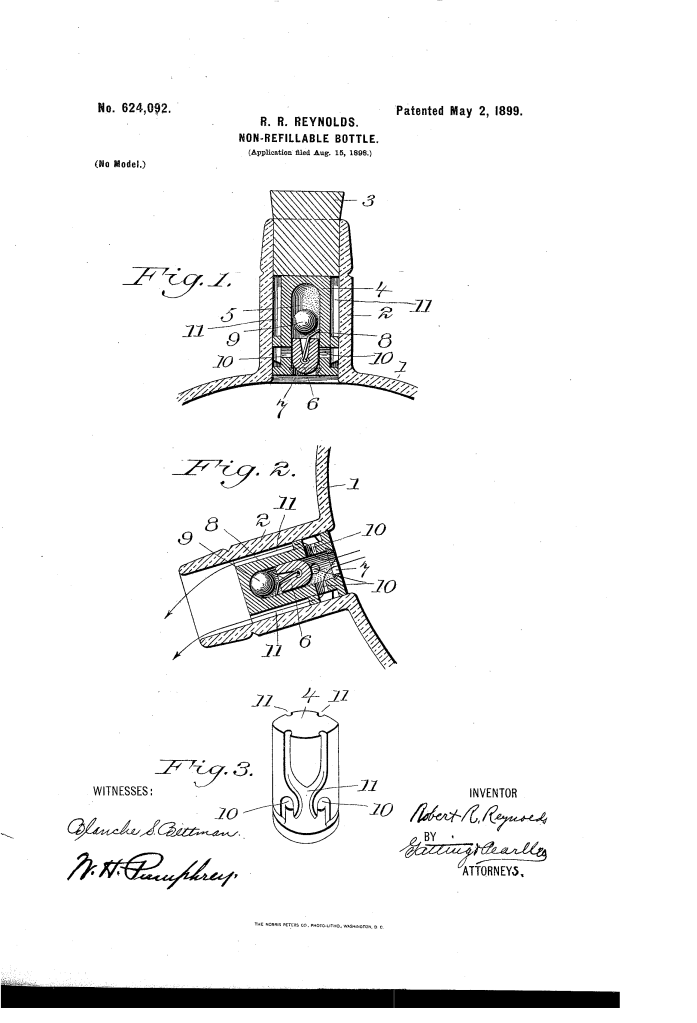

The device is a permanent, gravity-actuated valve stopper that locks closed when empty and is designed to resist tampering.

1. Permanent Valve Stopper

- Casing/Stopper (4): The stopper casing is ground and forcibly set into the bottle neck (2), ensuring a secure, permanent seal that prevents non-destructive removal. The casing has an interior chamber (5) opening downward into the bottle.

- Outflow Ports (10): The chamber (5) is provided with ports (10) for the liquid to escape when the bottle is tilted.

2. Gravity-Actuated Valve

- Gravity-Valve (6): A plug-valve slidingly seated in the chamber (5).

- Follower Weight (9) (Key Innovation): A weight (preferably spherical) confined within the chamber between the valve (6) and the upper closed end of the stopper.

- Function (Emptying): When the bottle is tilted, the follower weight (9) shifts due to gravity, moving off the valve (6) and allowing the valve to slide open and let the liquid pass.

3. Anti-Tamper Locking

- Locking Dog/Pawl (8): A self-disengaging dog (or pawl) formed of spring-wire is attached to the valve (6).

- Roughened Chamber Wall: The wall of the chamber (5) is roughened to facilitate engagement with the dog (8).

- Function (Locking): When the bottle is upright (or empty), the follower weight (9) rests on the valve (6), forcing the dog (8) outward into engagement with the roughened chamber wall. This action locks the valve closed, preventing it from being manipulated or siphoned open by external force (like a bent wire). When tilted, the weight shifts, releasing the dog.

Concepts Influenced by This Invention

Reynolds’s bottle design influenced subsequent packaging security and fluid control by pioneering weight-actuated internal locking combined with tamper-evidence.

- Weight-Dependent Valve Control: The core concept of using a follower weight (9) that shifts due to gravity to both enable and disable the valve’s operation influenced the design of specialty dispensing systems and industrial safety valves.

- Internal Locking for Tamper Resistance: The use of a follower weight to mechanically activate an internal lock (pawl 8) against the chamber wall is a key innovation. This provided a secure, non-siphonable seal that was resistant to tampering with tools, influencing the engineering of high-security containers.

- Permanent, Ground-Fit Sealing: The reliance on grinding the stopper (4) and the bottle neck (1) to ensure an accurate and forcibly sealed fit influenced early high-security packaging techniques where precise glass fitting was necessary to ensure the seal’s integrity against pressure and removal attempts.

- Fail-Safe Locking: The mechanism is designed to be in its locked state when upright and empty, the safest condition to prevent fraud. This fail-safe principle influenced the design of various security mechanisms.